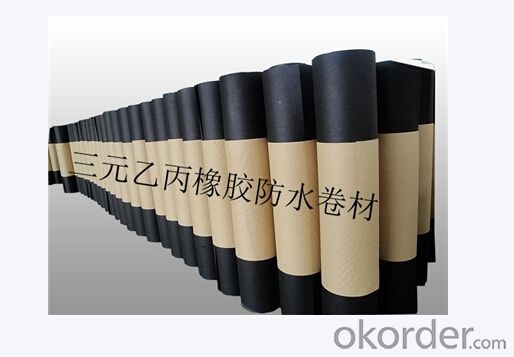

EPDM Swimming Waterproof EPDM Pond Liner with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM waterproofing membrane

1. Brief Introduction:

It is a kind of self-adhesive waterproof coiled material based on polymer rubber and superior asphalt, together with polyethylene film and aluminum foil as surface material or no film(Double-sided self-adhesive). And it adopts the package preventing-adhesion-isolation-layer package, and dividing into no fiber and polyester fiber two parts.The coiled material has perfect performances, simple operation, non-pollution and etc.

2. Characters:

1).Excellent anti aging performance ,service life up to 50 years.

2).High extension rate,high tensile strength ,small size changes at heat treatment.

3).Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4).Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5).Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6).Convenient application ,solid joint ,no environment pollution.

7).Chemical corrosion resistance ,can be used for special occasions.

8).Good anti-perforated.

3. Application:

It is widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing, especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

4. Package and Storage:

Each Roll with one plastic bag with or without pallets.

Keep in dry and ventilated place. Avoid shining and raining. Height of stack not more than 5 layers. Shelf life:12 months.

5. Specification:

Type | EPDM Waterproof Rubber Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

6. Installations:

1. adhere the EPDM membrane directly to the smooth and clean substrate like concrete deck, insulation board, etc.

2. Adjust membrane to make sure the overlaps is no less than 10cm and wiped clean.

3. Then, apply special adhesive evenly to both the substrate and the membrane laps or seam tape.

4. After minutes, press it securely and finish with sealant.

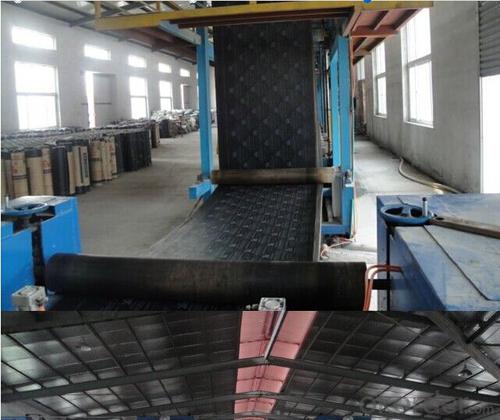

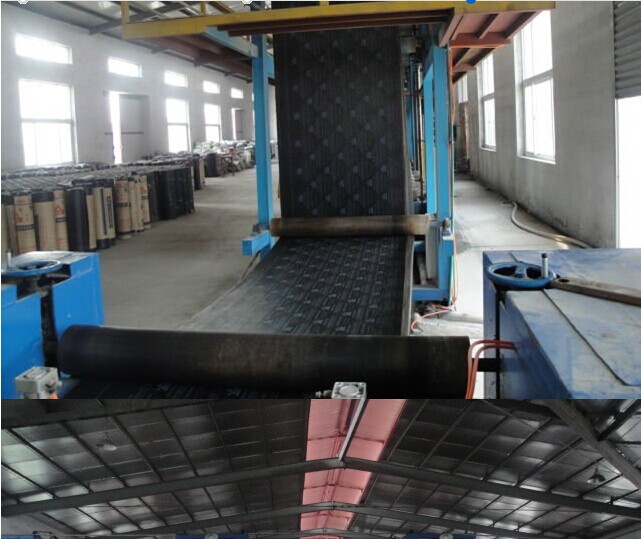

5. Some photos:

- Q: Can a waterproofing membrane be used on wood block surfaces?

- Yes, a waterproofing membrane can be used on wood block surfaces. Wood block surfaces, such as decks or wooden floors, can benefit from the application of a waterproofing membrane to protect against water damage and extend the lifespan of the wood. Waterproofing membranes create a barrier that prevents water from seeping into the wood, which can cause rot, warping, or decay over time. By applying a waterproofing membrane, the wood block surface can be effectively protected and maintained, ensuring its durability and longevity. However, it is important to choose a waterproofing membrane that is specifically designed for wood surfaces and follow the manufacturer's instructions for application to ensure the best results.

- Q: On the roof of the waterproofing membrane paving the direction of what are the requirements

- ?As for the upper and lower layers are not allowed between the vertical paving, the reason is that after the paving more heavy joints, and heavy seam is the most vulnerable to leakage of weak parts. ????????Dragon waterproof experts to remind you: things always have a dual nature. In the southern region, the temperature is high, rainy days, to the web paving brought a lot of difficulties. In order to waterproof roofing, when the rain is easy to coil joints, in addition to less than 3% of the roof slope, the remaining slope of the roof coil should take the vertical roof direction paving.

- Q: Does a waterproofing membrane prevent water infiltration through concrete?

- Water infiltration through concrete can be prevented by a waterproofing membrane. This type of membrane is applied to concrete surfaces to establish a barrier against water penetration. Its purpose is to be impermeable to water and to serve as a protective layer that seals the concrete surface. When installed correctly, the waterproofing membrane can successfully stop water from seeping through the concrete, safeguarding the structure against water damage and potential structural problems. Nevertheless, it is crucial to consider that the effectiveness of a waterproofing membrane relies on the quality of materials utilized, the installation procedure, and the maintenance of the membrane over time.

- Q: Can a waterproofing membrane be used on precast stone surfaces?

- Indeed, the utilization of a waterproofing membrane is viable on precast stone surfaces. Similar to all other concrete or masonry surfaces, precast stone surfaces are prone to water infiltration, which may lead to long-term damage. By applying a waterproofing membrane onto the precast stone surface, one can effectively prevent water penetration and shield the stone from moisture-related problems such as cracking, spalling, and efflorescence. This membrane establishes a barrier that hinders water seepage into the stone while still permitting it to respire and release any trapped moisture. Hence, it is crucial to select a waterproofing membrane that is compatible with the precast stone material and meticulously adhere to the manufacturer's instructions for proper application.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Yes, a waterproofing membrane can be used for temporary structures or tents. Waterproofing membranes are designed to provide a protective barrier against water, preventing it from penetrating the surface and causing damage. This makes them an ideal choice for temporary structures or tents, as they can effectively keep the interior dry during rain or other wet conditions. Additionally, waterproofing membranes are often lightweight and flexible, making them easy to install and remove, which is especially beneficial for temporary structures or tents that may need to be relocated or dismantled.

- Q: Can waterproofing membranes be used on both horizontal and vertical surfaces?

- Yes, waterproofing membranes can be used on both horizontal and vertical surfaces. Waterproofing membranes are designed to provide a barrier against water penetration and can be applied on various surfaces, including roofs, walls, floors, and even underground structures. They are versatile in their application and can be used to protect both horizontal surfaces such as flat roofs or balconies, as well as vertical surfaces like walls or foundations. The flexibility and durability of waterproofing membranes make them suitable for a wide range of construction projects, ensuring that water does not seep through and cause damage to the structure.

- Q: Are waterproofing membranes resistant to frost damage?

- Waterproofing membranes, in general, exhibit resistance towards frost damage. These membranes are specifically crafted to endure diverse weather conditions, which include freezing temperatures. They typically comprise modified bitumen, PVC, EPDM, or TPO, materials renowned for their exceptional frost and environmental resistance. These materials are engineered to maintain their flexibility and elasticity, even in low temperatures, ensuring the preservation of the waterproofing membrane's effectiveness in preventing water infiltration. Furthermore, meticulous installation methods and regular maintenance can augment the waterproofing membranes' resistance to frost damage.

- Q: Can a waterproofing membrane be used for pond or pool applications?

- Certainly! A waterproofing membrane is suitable for both pond and pool applications. Its main purpose is to create a barrier that prevents water from penetrating, making it an excellent choice for sealing ponds and pools. These membranes are typically made from synthetic materials like PVC, EPDM, or TPO, all of which have high resistance to water and UV rays. They come in different thicknesses and can be tailored to fit the specific dimensions of the pond or pool. Moreover, waterproofing membranes are incredibly durable and flexible, allowing them to withstand continuous exposure to water and the movement of the underlying substrate. In summary, utilizing a waterproofing membrane for pond or pool applications helps avoid leaks, extends the lifespan of the structure, and guarantees a safe and enjoyable water environment.

- Q: Does a waterproofing membrane require any curing time?

- Indeed, a curing time is typically necessary for a waterproofing membrane to fully bond and establish a robust, impermeable barrier. The duration of this curing period can differ based on the type of membrane employed and the instructions provided by the manufacturer. While the membrane is undergoing the curing process, precautions should be taken to shield it from foot traffic, water exposure, and any other potential sources of harm. Adhering to the recommended curing time is crucial in guaranteeing the membrane's effectiveness and durability.

- Q: Can waterproofing membranes be used on concrete floors?

- Yes, waterproofing membranes can be used on concrete floors. They are commonly used to protect concrete surfaces from water damage and can be applied to both new and existing concrete floors to prevent water penetration and moisture-related issues such as mold, mildew, and deterioration.

Send your message to us

EPDM Swimming Waterproof EPDM Pond Liner with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords