EPDM Self-adhesive Waterproof Membrane for Rooftop 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Rubber Waterproof Membrane:

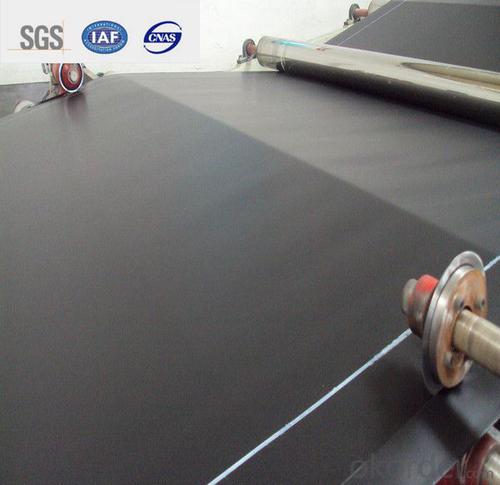

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

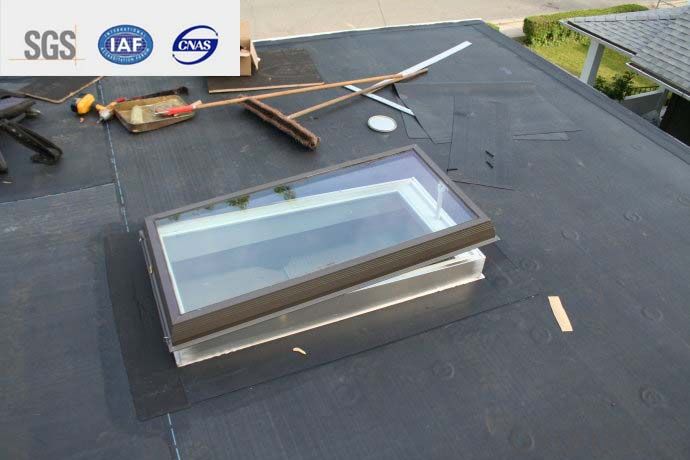

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for underground utility vaults?

- Yes, a waterproofing membrane can be used for underground utility vaults. Waterproofing membranes are commonly used to prevent water infiltration and protect structures from moisture damage. In the case of underground utility vaults, where there is a high risk of groundwater seepage, a waterproofing membrane can provide an effective barrier against water penetration, ensuring the vault remains dry and protected from potential water-related issues.

- Q: Is a waterproofing membrane resistant to cracking or shrinking?

- Yes, a waterproofing membrane is designed to be resistant to cracking and shrinking, providing a durable and long-lasting solution for preventing water penetration.

- Q: Can a waterproofing membrane be used for a parking lot?

- Indeed, a parking lot can benefit greatly from the utilization of a waterproofing membrane. Specifically engineered to create a safeguard against water infiltration, this remarkable membrane can be skillfully applied to a myriad of surfaces, encompassing parking lots. Its primary purpose is to thwart water-related damages, such as the formation of cracks and the degradation caused by the dreaded freeze-thaw cycles, ultimately leading to an elongated lifespan for the parking lot. Moreover, the implementation of a waterproofing membrane in a parking lot not only aids in the prevention of water leakage into the subbase, but it also fortifies its stability, effectively mitigating the possibility of exorbitant repairs. This intelligent investment not only bolsters the durability and longevity of the parking lot but also curtails the necessity for excessive maintenance efforts. In essence, the utilization of a waterproofing membrane for a parking lot serves as a prudent decision, ensuring enhanced endurance and reduced upkeep requirements.

- Q: Can a waterproofing membrane be used in areas with high water pressure?

- Yes, a waterproofing membrane can be used in areas with high water pressure. Waterproofing membranes are designed to withstand and prevent water penetration, making them suitable for use in areas where there is high water pressure. However, it is important to ensure that the membrane chosen is specifically rated and designed to handle the specific water pressure levels in order to ensure its effectiveness and durability.

- Q: Can a waterproofing membrane be used on green roofs?

- Yes, a waterproofing membrane can be used on green roofs. It is an essential component of the green roof system as it prevents water from penetrating the roof structure and causing damage. The waterproofing membrane ensures that the roof remains watertight and protects the building below from potential leaks.

- Q: Can a waterproofing membrane be used on nickel surfaces?

- Yes, a waterproofing membrane can be used on nickel surfaces. Waterproofing membranes are commonly used in construction and building projects to protect surfaces from water damage and moisture intrusion. They create a barrier that prevents water from penetrating through the surface and causing damage. Nickel surfaces, like any other metal surfaces, can be susceptible to corrosion and damage from water exposure. By applying a waterproofing membrane, the nickel surface can be effectively protected from water and moisture, extending its lifespan and maintaining its integrity. However, it is important to ensure that the specific waterproofing membrane being used is suitable for application on nickel surfaces. Different membranes may have different compatibility requirements, so it is recommended to consult with the manufacturer or a professional to ensure proper application and compatibility.

- Q: Are waterproofing membranes resistant to rodent and insect infestation?

- Waterproofing membranes are not typically designed with specific resistance against rodent and insect infestation in mind. While their main purpose is to safeguard structures from water damage, they might offer some degree of protection against pests. However, if rodents or insects are determined to invade a particular area, they can discover ways to circumvent or harm the membrane. To effectively prevent infestation by rodents and insects, it is recommended to adopt additional measures. These include sealing any gaps or cracks in the building, employing appropriate pest control methods, and adhering to good hygiene practices. By doing so, a more comprehensive approach can be achieved in keeping pests out and safeguarding the structure's integrity.

- Q: Can a waterproofing membrane be used on nickel surfaces?

- Yes, a waterproofing membrane can be used on nickel surfaces. The membrane will provide a protective barrier against moisture and prevent water penetration into the nickel surface.

- Q: Can a waterproofing membrane be used for bridges and overpasses?

- Bridges and overpasses can benefit from the use of waterproofing membranes. These membranes are widely employed in the construction industry to safeguard structures against water infiltration. They are specifically designed to create a barrier between the structure and moisture, effectively preventing water from seeping into the concrete or steel components. The installation of a waterproofing membrane significantly extends the lifespan of these structures by inhibiting corrosion, concrete degradation, and other damages caused by water exposure. Furthermore, these membranes offer protection against other environmental factors such as freeze-thaw cycles, chemicals, and UV radiation. Therefore, it is a commonplace practice in the industry to utilize waterproofing membranes for bridges and overpasses, as it enhances their durability and longevity.

- Q: Can a waterproofing membrane be applied in cold weather conditions?

- Applying a waterproofing membrane in cold weather is possible, but the temperature range may differ depending on the product and manufacturer guidelines. Certain membranes can endure cold temperatures and be applied as low as -20 degrees Celsius (-4 degrees Fahrenheit), while others may have a higher minimum application temperature. Following the manufacturer's instructions is crucial, as well as ensuring the surface is adequately prepared and free from ice, snow, or moisture. Consulting with an experienced professional contractor who has worked with waterproofing membranes in cold weather conditions is also recommended for optimal results.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Rooftop 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords