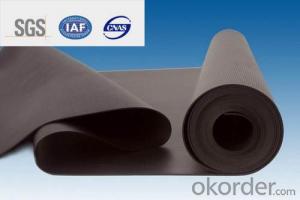

EPDM Waterproof Roofing Membrane Thickness with 1.5 mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Introduction:

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Product Features:

1. the excellent anti-aging, in the long term light, humidity, cold use of the naturalenvironment, small changes in physical properties, used in the temperature: From -50 degree Celsius to +80degree Celsious.

2.with outstanding ozone resistance, resistance to ultraviolet and atmospheric corrosion of many chemical corrosive substances.

Product Advantage:

1. high tensile strength, high elongation, high flexibility, capable of sustaining a puncture of hard material, good anti-crack, high adaptability of the grass roots' contraction and the crack and deformation, and give full play to extend the performance, playing the role of waterproofing.

2.long lifetime, high durability can achieve more than 25 years.

3.the cold construction operation, no environment pollution and simple operation.

FAQ:

Q: Can I visit your company?

A: Yes, welcome to visit our enterprise.

Q: Can I do the third party testing before loading?

A: Yes, we could accept the third party testing.

Q: Which kind of payment in your company?

A: We could accept TT, LC at sight, etc.

- Q: Are waterproofing membranes suitable for residential basements?

- Residential basements can indeed benefit from the use of waterproofing membranes. These membranes are specifically engineered to avert water infiltration and safeguard the basement against any harm caused by moisture. Whether applied on the interior or exterior walls, they create a formidable barrier against both water and dampness. This, in turn, helps to stave off problems like mold growth, water damage, and structural decay. With their excellent durability and ability to foster a dry and wholesome living space, waterproofing membranes emerge as a highly effective solution for residential basements.

- Q: Can a waterproofing membrane be used for underground utilities?

- Underground utilities can benefit from the use of a waterproofing membrane. These membranes are specifically designed to act as a barrier against water penetration, safeguarding the underlying structure from moisture damage. This becomes particularly significant for underground utilities, which face constant exposure to the surrounding soil and potential water seepage. Applying a waterproofing membrane to underground utilities, such as water pipes, sewer lines, or electrical conduits, aids in preventing water infiltration and subsequent corrosion or degradation of the materials. Acting as a protective layer, the membrane ensures that the utilities remain dry and free from moisture-related issues. Different types of waterproofing membranes are available, including sheet membranes, liquid membranes, and spray-applied membranes, each possessing unique properties and installation methods. The selection of the appropriate membrane relies on factors such as the specific utility, surrounding soil conditions, and additional requirements like chemical resistance or structural reinforcement. It is crucial to emphasize that proper installation and maintenance of the waterproofing membrane are vital for its effectiveness. Trained professionals should handle the installation, adhering to manufacturer guidelines and industry best practices. Regular inspections and maintenance are also necessary to ensure the membrane remains intact and functional over time. In conclusion, the utilization of a waterproofing membrane is indeed suitable for underground utilities. This application provides protection against water infiltration and preserves the integrity and longevity of the utilities.

- Q: Can a waterproofing membrane be used in roofs?

- Yes, a waterproofing membrane can be used in roofs. In fact, it is a commonly used method for protecting roofs from water damage. A waterproofing membrane is typically made of a durable material, such as rubber or modified bitumen, and is applied to the roof surface to create a barrier against water penetration. This membrane acts as a protective layer that prevents water from seeping into the underlying structure of the roof, thus preventing leaks and potential damage. Waterproofing membranes are especially useful for flat or low-sloped roofs, where water can easily accumulate and cause problems. Additionally, these membranes can be applied to various types of roofing materials, including concrete, metal, and asphalt, making them versatile and suitable for different roof types. Overall, using a waterproofing membrane in roofs is an effective way to enhance their durability and longevity, while also providing reliable protection against water infiltration.

- Q: Can waterproofing membranes be used for planter boxes?

- Yes, waterproofing membranes can be used for planter boxes. Waterproofing membranes are designed to prevent water from penetrating surfaces, and can be applied to various materials such as wood, concrete, or metal. By applying a waterproofing membrane to the inside of a planter box, it can help to protect the material from water damage, prolonging the lifespan of the planter box. This is especially beneficial for wooden planter boxes, as the membrane can prevent the wood from rotting or deteriorating over time. Additionally, the waterproofing membrane can help to retain moisture within the planter box, preventing water from seeping out and ensuring that the plants receive sufficient water for healthy growth. Overall, using waterproofing membranes for planter boxes can help to improve their durability and performance, making them a popular choice for both indoor and outdoor gardening.

- Q: Can a waterproofing membrane be used for a school building foundation?

- A school building foundation can indeed utilize a waterproofing membrane. These membranes are specifically created to safeguard structures by preventing water from infiltrating. They are commonly employed in various construction scenarios, including building foundations. By applying a waterproofing membrane to the foundation walls, it can effectively shield the building from water-related harm and prevent issues caused by moisture, such as mold, decay, and structural damage. This is especially crucial for school buildings due to their extensive foundations and the possibility of heavy usage and water exposure. Thus, the use of a waterproofing membrane is a viable solution to ensure the durability and structural soundness of the school building foundation.

- Q: Can a waterproofing membrane be used in earthquake-prone areas?

- Yes, a waterproofing membrane can be used in earthquake-prone areas. Waterproofing membranes are designed to provide a barrier against moisture penetration, and they can also offer some degree of flexibility and elasticity. This allows them to withstand the movement and vibrations caused by earthquakes, helping to protect the structure from water damage and potential leaks. However, it is important to ensure that the chosen membrane meets the specific requirements and standards for earthquake-prone areas to ensure its effectiveness and durability.

- Q: Can a waterproofing membrane be used on rubber surfaces?

- Yes, a waterproofing membrane can be used on rubber surfaces.

- Q: Are waterproofing membranes resistant to chemicals?

- Yes, waterproofing membranes are generally resistant to chemicals. They are designed to provide a barrier against water, moisture, and various chemicals, making them highly effective in protecting surfaces against chemical damage.

- Q: Can a waterproofing membrane be installed in areas with high humidity?

- Yes, a waterproofing membrane can be installed in areas with high humidity. In fact, high humidity can be a contributing factor to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the humidity levels in the area. However, it is important to ensure that the membrane is properly installed and sealed to prevent any moisture from seeping through. Additionally, it may be necessary to take extra precautions in areas with high humidity, such as using a moisture barrier or dehumidifiers, to further protect against potential water damage.

- Q: Can a waterproofing membrane be used on roofs?

- Yes, a waterproofing membrane can be used on roofs. Waterproofing membranes are often applied to roofs to provide a protective barrier against water penetration and ensure the roof remains watertight.

Send your message to us

EPDM Waterproof Roofing Membrane Thickness with 1.5 mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords