EPDM Waterproofing Roofing Membrane with 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

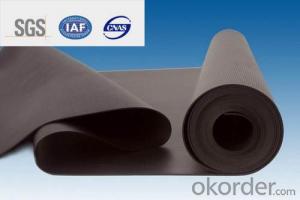

Description Of EPDM Rubber Waterproof Membrane:

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Main Features of EPDM Rubber Waterproof Membrane:

1>Excellent anti-aging performance, service life up to 50 years

2>Working well with in -40°C to 100°C,it can be constructed with a single layer in ambient temperature.

3>Waterproofing on various kinds of underground project,industrial of civil buildings and structures.

4>high extension rate, high tensile strength, small size changes at heat treatment

5>Good plant roots penetrability resistance and can be made waterproofing layer of planting roof

6>Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem .

7>Good low temperature flexibility, and good performance of adapting to ambient temperature changes.

8>Convenient application ,solid joint, no environment pollution

9>chemical corrosion Resistance, can be used for special occasions

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Does a waterproofing membrane require any specific cleaning or maintenance procedures?

- To ensure the longevity and effectiveness of a waterproofing membrane, it is necessary to follow specific cleaning and maintenance procedures. Regular cleaning and maintenance are important to prevent the accumulation of debris, dirt, and contaminants that could compromise the membrane's ability to keep water out. The exact procedures for cleaning and maintenance may vary depending on the type of waterproofing membrane used, but there are some general guidelines to follow. Firstly, it is crucial to frequently inspect the membrane for any signs of damage, such as cracks, tears, or deterioration. If any issues are found, they should be addressed promptly to prevent further damage. When it comes to cleaning, it is recommended to use a soft-bristle broom or a leaf blower to remove loose debris or dirt from the membrane surface. It is important to avoid harsh chemicals or abrasive materials that could harm the membrane. Instead, a mild detergent or specialized cleaning solution recommended by the manufacturer should be used. The surface can be gently scrubbed with a soft brush or sponge and thoroughly rinsed with clean water. Additionally, it is vital to keep the surrounding drainage systems clear and free from obstructions. Regular inspection and cleaning of gutters, downspouts, and drains are necessary to ensure proper water flow and prevent potential water damage. Lastly, it is advisable to have the waterproofing membrane professionally inspected and maintained on a regular basis. This will help identify any potential issues early on and ensure that the membrane is functioning optimally. By following these specific cleaning and maintenance procedures, the lifespan of the waterproofing membrane can be prolonged, and its effectiveness in preventing water infiltration can be maintained.

- Q: Is a waterproofing membrane resistant to algae or moss growth?

- Yes, a waterproofing membrane is typically resistant to algae or moss growth. Waterproofing membranes are designed to create a barrier against water infiltration, preventing moisture from seeping into the underlying structure. These membranes are typically made of materials that are not conducive to the growth of algae or moss, such as synthetic polymers or rubberized compounds. Additionally, waterproofing membranes are often treated with additives that inhibit the growth of organic matter, including algae or moss. However, it is important to note that over time, if the membrane is exposed to constant moisture or damp conditions, it may become a breeding ground for algae or moss. Therefore, regular maintenance and cleaning are important to ensure the longevity and effectiveness of the waterproofing membrane.

- Q: Does a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth by creating a barrier that prevents moisture from seeping into walls, floors, or other surfaces. By keeping the area dry, it reduces the conditions necessary for mold and mildew to thrive. However, it is important to note that a waterproofing membrane alone may not completely eliminate mold and mildew, as proper ventilation and maintenance are also crucial in preventing their growth.

- Q: Can a waterproofing membrane be used for a podium deck?

- Indeed, a podium deck can utilize a waterproofing membrane. A podium deck refers to an elevated platform or structure commonly found in commercial buildings or multi-story residential complexes. Given its raised position, a podium deck is exposed to various weather elements, including rain and moisture. Consequently, it becomes imperative to implement a dependable waterproofing system to shield the underlying structure from water-related harm. A waterproofing membrane emerges as a popular option for podium decks due to its ability to serve as an effective barrier against water infiltration. Generally, this membrane is applied beneath the deck's surface, acting as a protective layer that thwarts water from permeating the underlying structure. Its design prioritizes durability, flexibility, and resistance to weathering, guaranteeing long-term protection for the deck. Additionally, a waterproofing membrane can yield supplementary advantages for a podium deck. It can function as a vapor barrier, preventing the accumulation of moisture within the structure, which could lead to mold growth and material deterioration. Moreover, certain waterproofing membranes offer heightened UV resistance, contributing to the deck's longevity and aesthetic appeal preservation. When selecting a waterproofing membrane for a podium deck, it is crucial to consider factors such as the deck's design, projected foot traffic levels, and local climate conditions. Different membrane types, including sheet membranes, liquid membranes, or spray-applied membranes, may be suitable depending on the specific project requirements. In conclusion, employing a waterproofing membrane indeed proves suitable for a podium deck. It furnishes a reliable and effective solution for safeguarding the deck and underlying structure from water damage, thereby ensuring the durability and functionality of the podium deck.

- Q: Can a waterproofing membrane be used for loading docks or ramps?

- Yes, a waterproofing membrane can be used for loading docks or ramps. A waterproofing membrane is designed to protect surfaces from water damage by creating a barrier that prevents water from seeping through. Loading docks and ramps are exposed to various weather conditions and can be prone to water infiltration, which can cause damage over time. Applying a waterproofing membrane to these surfaces can help to prevent water penetration, protecting the structure and increasing its lifespan. Additionally, a waterproofing membrane can also provide added benefits such as slip resistance, protecting against chemical spills, and reducing maintenance costs.

- Q: Can waterproofing membranes be used on concrete dams?

- Yes, waterproofing membranes can be used on concrete dams. In fact, they are commonly used in the construction and maintenance of concrete dams to prevent water leakage and seepage. Waterproofing membranes are designed to create a barrier that is resistant to water penetration, protecting the concrete surface of the dam from damage caused by water. These membranes can be applied to both the interior and exterior surfaces of the dam, providing a reliable and long-lasting solution for waterproofing. Additionally, waterproofing membranes can also help to mitigate the risk of waterborne deterioration, such as freeze-thaw damage and corrosion of reinforcement, thereby extending the lifespan of the concrete dam.

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- Yes, a waterproofing membrane can be used on modified bitumen roofs. In fact, it is a common practice to install a waterproofing membrane over modified bitumen roofs to provide an additional layer of protection against water infiltration. This is especially important in areas with heavy rainfall or where the roof is prone to frequent exposure to water. The waterproofing membrane helps to seal any potential cracks or gaps in the modified bitumen roofing system, preventing water from seeping through and causing damage to the underlying structure. Additionally, the waterproofing membrane can also enhance the overall durability and longevity of the roof by protecting it from the harmful effects of moisture.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures and tears. It is specifically engineered to provide a durable barrier that can withstand potential damage from sharp objects or external forces.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Yes, a waterproofing membrane can be used in crawlspaces or basements. In fact, it is highly recommended to use waterproofing membranes in these areas to prevent moisture infiltration and water damage. Crawlspaces and basements are prone to water seepage and high humidity levels, which can lead to mold growth, structural issues, and damage to stored items. A waterproofing membrane acts as a barrier against water intrusion by effectively sealing the foundation walls and floor. It creates a watertight seal that prevents water from seeping into the space, keeping it dry and protected. Additionally, waterproofing membranes also help to control moisture levels by reducing condensation and humidity, thereby creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is an essential measure to ensure the longevity and integrity of the structure and to safeguard against potential water-related problems.

- Q: Can a waterproofing membrane be used in hospitals or healthcare facilities?

- Yes, a waterproofing membrane can be used in hospitals or healthcare facilities. In fact, it is highly recommended to use waterproofing membranes in these settings due to the critical need for maintaining a clean and hygienic environment. Waterproofing membranes are typically applied on floors, walls, and ceilings to prevent water or moisture infiltration, which can lead to mold growth, deterioration of building materials, and compromise the structural integrity of the facility. By using waterproofing membranes, healthcare facilities can effectively protect against water damage, facilitate easier cleaning and maintenance, and prevent the growth of bacteria and other harmful microorganisms. Additionally, waterproofing membranes can also help in managing moisture levels, thereby reducing the risk of slips and falls, which is especially crucial in areas where patients, staff, and visitors frequent. Overall, waterproofing membranes are a valuable asset in ensuring the safety, durability, and cleanliness of hospitals and healthcare facilities.

Send your message to us

EPDM Waterproofing Roofing Membrane with 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords