1.5mm EPDM membrane waterproofing For Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

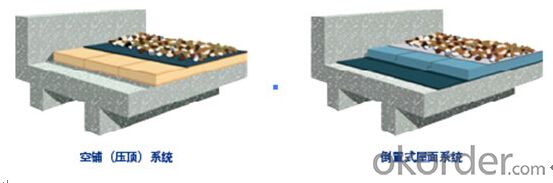

ROOF WATERPROOF SYSTEM-

EPDM MEMBRANE/COIL is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Application Scope

• Roofs, Basement, Toilet

•Industrial and civil building waterproofing

•Geo-synthetic liner for swimming pool, channels, irrigation system

•Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Advantagee

•Excellent weather-ability, durability and size stability

•Good adaptability to high and low temperature, UV resistant and anti-corrosion

•High tensile strength and good elongation, accommodating to structure movement

•Easy installation, solid joint, and no environmental pollution

•Good rooting penetration resistance

•Service life up to 50 years

Storage:

Shelf life is 12 months. Store in a cool and dry place with

original packing.

5,Demension:

1.2mmx1.2mx20m;1.5mmx1.2mx20m;2.0mmx1.2mx20m

Advantages

Technical Parameters

| Item | Index | ||||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

product show

factory show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: What are the requirements for the storage of waterproofing membranes?

- Prohibited sun exposure, exposure easily deformed.

- Q: Can a waterproofing membrane be walked on?

- Yes, a waterproofing membrane can be walked on, but it depends on the specific type of membrane and the intended use. Some waterproofing membranes, such as those used in roofing applications, are designed to be walked on during installation and maintenance. These membranes are typically more durable and can withstand foot traffic without being damaged. However, it's always important to follow the manufacturer's guidelines and recommendations to ensure that the membrane remains intact and continues to provide effective waterproofing protection. In other cases, such as with certain types of below-grade waterproofing membranes, walking on the membrane may not be recommended as it could potentially compromise its performance. It's best to consult with a professional or refer to the manufacturer's instructions to determine whether walking on a specific waterproofing membrane is safe and appropriate.

- Q: Can a waterproofing membrane be used for industrial facilities and factories?

- Indeed, industrial facilities and factories can utilize a waterproofing membrane. These establishments frequently feature areas that are exposed to moisture, such as basements, rooftops, and storage spaces. These particular areas are prone to water leakage and damage, which can lead to expensive repairs and operational downtime. A waterproofing membrane serves as an exceptionally effective solution for safeguarding these areas against water infiltration. It is a pliable and enduring barrier that is applied to surfaces, preventing water from penetrating through. Waterproofing membranes are engineered to withstand a range of environmental conditions, including temperature fluctuations, UV exposure, and chemical exposure, making them well-suited for industrial settings. Through the installation of a waterproofing membrane, industrial facilities and factories can avert water damage, mold growth, and structural decay caused by moisture. This preserves a safe and functional environment for workers and equipment, while also guaranteeing the longevity of the facility. Furthermore, a waterproofing membrane can contribute to enhanced energy efficiency by reducing heat loss through insulation and preventing water-related harm to HVAC systems. All in all, the utilization of a waterproofing membrane in industrial facilities and factories represents a practical and cost-effective approach to ensuring the protection and longevity of the facility.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Areas with extreme weather conditions, such as hurricanes or snowstorms, can benefit from the use of a waterproofing membrane. These membranes are designed to create a protective barrier against water infiltration and can withstand various weather conditions effectively. They are made from moisture-resistant materials and can be installed in roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes play a crucial role in preventing water damage. They create a barrier that keeps water out, even during heavy rainfall or storm surges. These membranes are often reinforced and possess high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas experiencing heavy snowstorms, waterproofing membranes are valuable in preventing water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring their integrity and leak prevention in freezing conditions. However, it is essential to select the appropriate type of waterproofing membrane for the specific weather conditions in the area. Different membranes offer varying levels of resistance to extreme weather, so consulting with a professional is advisable to determine the most suitable membrane for the climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: What is sbs, app modified asphalt waterproofing membrane

- Compared to the use of SBS waterproofing membrane to use a larger range. But each has its own advantages and disadvantages, according to the local environment and the actual situation of the building in combination with the characteristics of two kinds of coil to choose materials. You have to compare the next, I can only tell you SBS waterproofing membrane prices than APP waterproofing membrane high.

- Q: Can waterproofing membranes be used on retaining walls?

- Yes, waterproofing membranes can be used on retaining walls. These membranes are designed to prevent water penetration and can help protect the retaining wall from moisture damage.

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- Yes, a waterproofing membrane can be used on modified bitumen roofs. In fact, it is a common practice to enhance the waterproofing capabilities of modified bitumen roofs by applying a separate waterproofing membrane on top. This additional layer provides an extra barrier against water infiltration and helps prolong the lifespan of the roof.

- Q: Can waterproofing membranes be applied in cold weather?

- Indeed, waterproofing membranes are capable of being applied in chilly conditions. Nevertheless, it is imperative to take into account several factors when carrying out the application of these membranes in low temperatures. The curing process of the membrane can be affected by cold weather, which has the potential to decelerate it. Consequently, it is of utmost importance to ensure that the surface to be waterproofed is devoid of moisture, ice, or frost prior to the application of the membrane. Furthermore, certain waterproofing products might possess specific temperature prerequisites for attaining optimal performance, thus referring to the manufacturer's guidelines becomes indispensable. In colder temperatures, the employment of specialized adhesives or primers tailored for cold weather applications may also become necessary. All in all, by adopting appropriate precautions and utilizing suitable materials, it is feasible to successfully apply waterproofing membranes in cold weather.

- Q: Can a waterproofing membrane be used for train platforms?

- Train platforms can indeed benefit from the application of a waterproofing membrane. Given their exposure to different weather conditions like rain and snow, it is important to address potential water damage and deterioration over time. One effective method is to install a waterproofing membrane on the surface of the platform. This protective barrier prevents water from seeping through and causing harm to the underlying structure. Consequently, this approach not only prolongs the platform's lifespan but also reduces maintenance costs and ensures the safety of passengers and personnel. In addition, the use of a waterproofing membrane can help prevent the growth of mold and mildew, which can negatively impact the health of those using the train platform. All in all, utilizing a waterproofing membrane on train platforms proves to be a practical and efficient solution for safeguarding against water damage and maintaining the infrastructure's longevity.

- Q: How does a waterproofing membrane handle settlement of adjacent structures?

- A waterproofing membrane can handle settlement of adjacent structures by being flexible and able to accommodate movement. It is designed to withstand and adapt to shifts in the surrounding structures without compromising its integrity or waterproofing capabilities.

Send your message to us

1.5mm EPDM membrane waterproofing For Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords