EPDM Self-adhesive Waterproof Membrane for Rooftop Foam Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Self-adhesive Waterproof Membrane Foam Material:

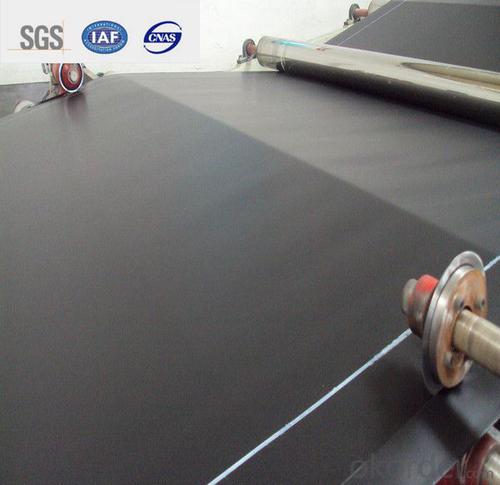

1. EPDM Self-adhesive waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM Self-adhesive waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM Self-adhesive waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Self-adhesive Waterproof Membrane Foam Material:

1 High tear

2 High puncturing strength

3 Great temperature resistance.

4 High dimensional stability

Specifications of EPDM Self-adhesive Waterproof Membrane Foam Material:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

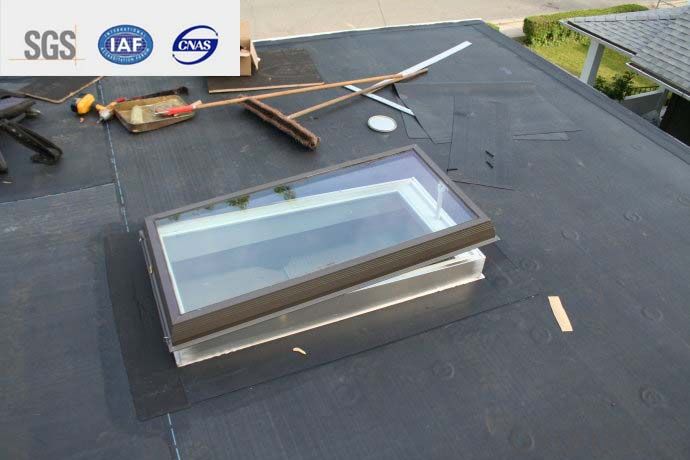

Applications of EPDM Rubber Waterproof Membrane Foam Material:

Widely used for kinds of cold/hot medium piping and containers in central control air condition, construction, chemical

industry, medicine, light industry, textile process, metallurgy, boat, vehicle, electrical apparatus and others fields to reduce

cold/thermal loss.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in historical or heritage buildings?

- Yes, a waterproofing membrane can be used in historical or heritage buildings. However, it should be done with caution and expertise to ensure that the membrane does not compromise the historical integrity or aesthetic value of the building. The selection and installation of the membrane should be carried out by professionals who understand the specific requirements and challenges associated with preserving the architectural significance of such buildings.

- Q: Can a waterproofing membrane be used for swimming pool decks and patios?

- Yes, a waterproofing membrane can be used for swimming pool decks and patios. A waterproofing membrane is designed to prevent water penetration and protect the underlying structure from water damage. Swimming pool decks and patios are constantly exposed to water, whether through splashing or rain, making them susceptible to water damage. By applying a waterproofing membrane, you can ensure that the pool deck or patio remains protected and free from water-related issues such as cracking, mold, or deterioration. This membrane acts as a barrier, preventing water from seeping into the concrete or other materials, thus extending the lifespan of the pool deck or patio. It is essential to choose a high-quality and suitable waterproofing membrane specifically designed for outdoor use to ensure optimal performance and durability.

- Q: Are there any specific considerations for installing a waterproofing membrane on wood surfaces?

- Yes, there are several specific considerations for installing a waterproofing membrane on wood surfaces. Firstly, it is important to ensure that the wood surface is clean, dry, and free from any debris or loose material. This will help in achieving a proper adhesion of the waterproofing membrane. Additionally, it is crucial to choose a membrane specifically designed for wood surfaces, as they may require additional flexibility and resistance to expansion and contraction. It is also recommended to apply a primer or sealer to the wood surface before installing the membrane to improve its adhesion and longevity. Lastly, regular inspection and maintenance of the waterproofing membrane is essential to identify any potential issues and ensure its effectiveness over time.

- Q: Can a waterproofing membrane be used in bathrooms?

- Yes, a waterproofing membrane can be used in bathrooms. In fact, it is highly recommended to use a waterproofing membrane in bathrooms to prevent water damage and leakage. The membrane acts as a barrier, preventing moisture from seeping into the walls or floors, ensuring the longevity and durability of the bathroom.

- Q: Can a waterproofing membrane be used on roofs with solar panels?

- Yes, a waterproofing membrane can be used on roofs with solar panels. In fact, it is highly recommended to use a waterproofing membrane in such cases to ensure that the roof remains watertight and protected from any potential leaks. The waterproofing membrane acts as a barrier that prevents water from seeping into the roof structure and causing damage. It is important to choose a waterproofing membrane that is compatible with the solar panels and does not interfere with their performance. Additionally, proper installation techniques should be followed to ensure a seamless integration of the membrane and solar panels.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Indeed, a waterproofing membrane is capable of being employed on walls located below ground level. In fact, it is highly advisable to utilize a waterproofing membrane on such walls so as to shield them against infiltration of water and potential harm caused by moisture. Walls situated below ground level are especially susceptible to water penetration due to their proximity to the ground and the possibility of hydrostatic pressure. A waterproofing membrane serves as a protective barrier, effectively preventing water from seeping into the walls and leading to issues such as mold, mildew, decay, and structural impairment. Moreover, it aids in maintaining the interior of the edifice in a dry condition, thereby averting potential problems related to moisture.

- Q: Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. However, it is important to consider the specific needs and requirements of the building. The use of a waterproofing membrane should be carefully assessed and integrated into the building's preservation and conservation plans to ensure compatibility with its historic fabric and materials. Professional advice and expertise should be sought to ensure the appropriate selection and installation of the waterproofing membrane without compromising the building's historic integrity.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Installing a waterproofing membrane on precast concrete surfaces requires specific considerations. Here are some important points to remember: 1. Proper Surface Preparation: Before applying the waterproofing membrane, it is crucial to prepare the precast concrete surface correctly. This involves cleaning the surface, removing loose particles, and ensuring it is dry and free from any contaminants. 2. Compatibility: It is important to select a waterproofing membrane that is suitable for precast concrete surfaces. Some membranes may not adhere well or provide effective waterproofing on this type of substrate. Therefore, it is essential to choose a membrane specifically designed for use on precast concrete. 3. Ensuring Adhesion: Properly adhering the waterproofing membrane to the precast concrete surface is vital. It is important to carefully follow the manufacturer's instructions, including any surface priming or preparation requirements for optimal adhesion. Proper adhesion will prevent water infiltration and concrete damage. 4. Joint Treatment: Precast concrete surfaces often have joints between panels or components. These joints need proper treatment to maintain the system's waterproofing integrity. This may involve using joint sealants or tapes designed specifically for waterproofing purposes. 5. Considering Durability: Consider the durability and longevity of the waterproofing membrane. Precast concrete surfaces are exposed to various weather conditions and environmental factors. Therefore, it is crucial to choose a membrane that can withstand these conditions and provide long-term protection against water penetration. 6. Quality Assurance: It is recommended to work with experienced professionals or certified installers to ensure the proper installation of the waterproofing membrane on precast concrete surfaces. This minimizes the risk of installation errors and ensures that the waterproofing system performs as intended. By considering these factors, installing a waterproofing membrane on precast concrete surfaces can effectively protect the concrete from water damage and extend its lifespan.

- Q: Can a waterproofing membrane be used for retaining walls?

- A waterproofing membrane is suitable for retaining walls as it helps to prevent water from penetrating and causing damage or structural failure. These membranes, made of materials like rubber, PVC, or bituminous compounds, are installed on the inner side of the retaining wall to create a barrier against water infiltration. In addition to protecting the wall's stability, some membranes also offer resistance to root penetration, UV protection, and flexibility to accommodate movement. However, it is crucial to consider factors such as the type of retaining wall, water pressure, and local climate conditions when selecting the right waterproofing membrane. It is advisable to consult with a professional engineer or contractor to ensure the most suitable waterproofing solution for your specific retaining wall project.

- Q: How thick is a typical waterproofing membrane?

- The thickness of a waterproofing membrane can differ depending on its purpose and the specific product employed. However, the typical range for these membranes is usually between 0.5mm and 2mm. Thinner membranes are commonly utilized for interior applications such as showers, whereas thicker membranes are more commonly applied to roofs or underground structures. To ensure the correct thickness is chosen for a particular waterproofing project, it is crucial to consult the manufacturer's guidelines and specifications.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Rooftop Foam Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords