EPDM Self-adhesive 22Waterproof Membrane for Rooftop

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

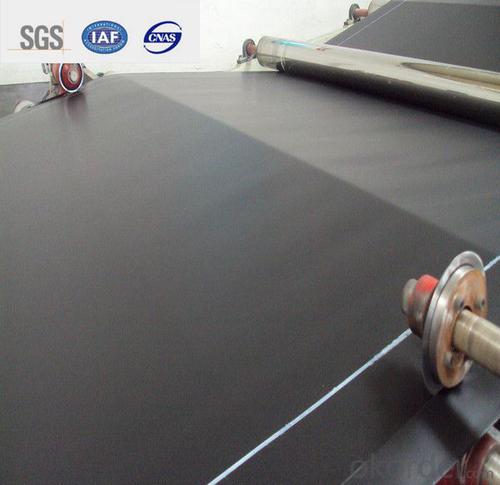

Description Of EPDM Self-adhesive Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Self-adhesive Waterproof Membrane:

1 High tear

2 High puncturing strength

3 Great temperature resistance.

4 High dimensional stability

Specifications of EPDM Self-adhesive Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

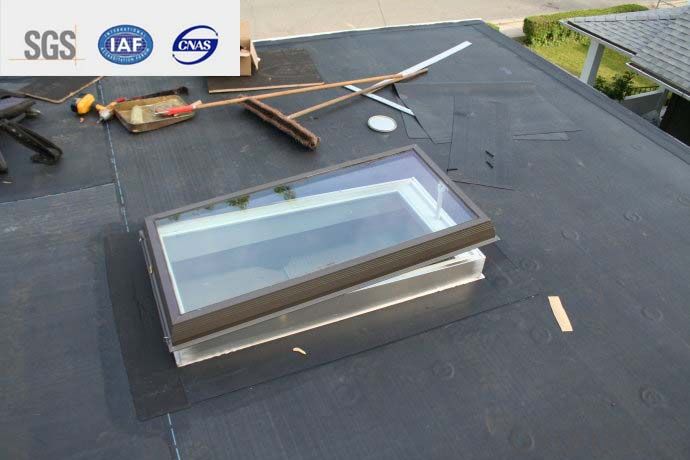

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How does a waterproofing membrane handle water infiltration from above?

- A waterproofing membrane handles water infiltration from above by creating a barrier that prevents water from seeping through the surface it is applied on. It effectively repels and redirects the water away, ensuring that it does not penetrate the underlying structure or cause any damage.

- Q: Can a waterproofing membrane be used on metal surfaces?

- Yes, a waterproofing membrane can be used on metal surfaces. Waterproofing membranes are designed to protect surfaces from water penetration and can be applied to a variety of materials, including metal. These membranes are typically made of materials such as modified bitumen, EPDM, PVC, or TPO, which provide a durable and watertight barrier. Applying a waterproofing membrane to a metal surface can help prevent corrosion, rust, and water damage, making it a suitable solution for protecting metal structures, roofs, or surfaces that are exposed to moisture or water. However, it is important to ensure that the specific waterproofing membrane being used is compatible with the type of metal surface and that proper installation guidelines are followed for optimal performance and longevity.

- Q: Can a waterproofing membrane be used for underground communication vaults?

- Yes, a waterproofing membrane can be used for underground communication vaults. Waterproofing membranes are commonly used in construction to prevent water infiltration and provide protection against moisture. In the case of underground communication vaults, where moisture and potential water leakage can be a concern, a waterproofing membrane can help ensure the integrity and longevity of the structure by creating a barrier against water intrusion.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Vehicular traffic areas can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier that prevents water from seeping through and causing damage to surfaces. In areas like parking decks or driveways, it is crucial to protect the underlying structure from water infiltration, which can lead to corrosion, deterioration, and expensive repairs. By utilizing a waterproofing membrane that is specifically designed for vehicular traffic, the surface can be effectively safeguarded from water damage, as well as other potential contaminants such as oil and chemicals. These membranes are typically more durable and capable of withstanding the weight and impact of vehicles, ensuring long-lasting protection. Furthermore, certain waterproofing membranes even offer slip-resistant properties, making them suitable for areas where vehicles require traction. Nevertheless, it is important to seek guidance from a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas, taking into account factors such as traffic volume, load capacity, and climate conditions.

- Q: Are waterproofing membranes suitable for high-traffic areas?

- Yes, waterproofing membranes are suitable for high-traffic areas. Waterproofing membranes are designed to provide a protective barrier against water infiltration, preventing water damage and maintaining the integrity of the structure. High-traffic areas, such as walkways, driveways, parking lots, and other heavily used spaces, are prone to constant exposure to water, which can lead to structural damage and deterioration over time. By applying a waterproofing membrane, these areas can be effectively protected from water intrusion, ensuring their durability and longevity. Additionally, waterproofing membranes are often designed to be slip-resistant, providing an added safety feature in high-traffic areas. Therefore, using waterproofing membranes in high-traffic areas is a wise choice to mitigate water-related issues and maintain the structural integrity of the space while ensuring the safety of occupants.

- Q: How does a waterproofing membrane handle exposure to chemicals or solvents?

- A waterproofing membrane is designed to be resistant to chemicals and solvents, allowing it to handle exposure without being damaged or deteriorated.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic or vehicle loadings?

- Yes, a waterproofing membrane can be used in areas with heavy foot traffic or vehicle loadings. However, it is important to choose a membrane that is specifically designed for such applications to ensure durability and longevity. These specialized membranes are typically thicker and more resistant to wear and tear. Additionally, consideration should be given to the type of traffic or loading that the area will experience. For example, areas with vehicular traffic may require a membrane with higher compressive strength to withstand the weight of vehicles. In summary, while waterproofing membranes can be used in high-traffic or heavy loading areas, it is crucial to select the appropriate type of membrane that meets the specific demands of the application.

- Q: Can waterproofing membranes be used on concrete pipes?

- Concrete pipes can indeed utilize waterproofing membranes. These membranes are frequently employed to thwart the ingress of water and safeguard concrete structures against moisture-induced harm. Like any other concrete structure, concrete pipes are vulnerable to water infiltration, which can result in decay and a shortened lifespan. By applying a waterproofing membrane to concrete pipes, a barrier against water can be established, thus averting potential complications such as leaks, cracks, and corrosion. Typically, the membrane is administered to the exterior of the pipe, forming a protective layer that thwarts water from permeating the concrete. This measure contributes to prolonging the pipes' lifespan and guaranteeing their long-standing durability.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Yes, a waterproofing membrane can be used on stadium seating areas. Waterproofing membranes are typically used to protect structures from water damage, including roofs, basements, and decks. Stadium seating areas are often exposed to the elements, including rain and snow, which can lead to water damage if not properly protected. By applying a waterproofing membrane, the seating areas can be safeguarded against water infiltration, preventing potential issues such as mold growth, deterioration of materials, and structural damage. It is important to choose a high-quality waterproofing membrane that is specifically designed for outdoor use and can withstand heavy foot traffic, ensuring long-lasting protection for the stadium seating areas.

- Q: Can a waterproofing membrane be used on plaster surfaces?

- Plaster surfaces can benefit from the use of a waterproofing membrane. Due to its porous nature, plaster readily absorbs water, which can lead to damage caused by moisture. By applying a waterproofing membrane to plaster surfaces, a barrier is created to prevent water infiltration. This protective measure safeguards against problems like mold, mildew, and deterioration caused by moisture. Before applying the membrane, it is crucial to ensure the plaster surface is clean, dry, and devoid of loose or flaking material. It is also important to follow proper surface preparation and application techniques to guarantee the effectiveness and durability of the waterproofing system.

Send your message to us

EPDM Self-adhesive 22Waterproof Membrane for Rooftop

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords