EPDM Rubber Waterproofing Membrane Underground Leakage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

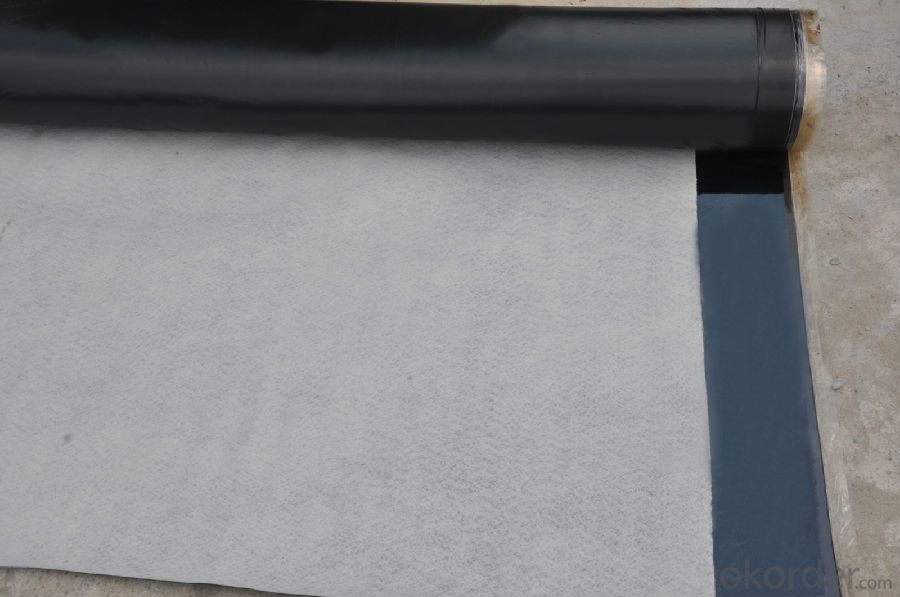

Introduction for EPDM Waterproofing Membrane:

Waterproof membrane for roof adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

Application of EPDM Waterproofing Membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

Specification of EPDM Waterproofing Membrane:

No. | Item | Unit | Standard Request | |

1 | Variation in Dimension | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | No Negative Value | ||

2 | Tensile Strength at Break(Normal Temperature) | Mpa | ≥7.5 | |

Tensile Strength at Break(60ºC) | Mpa | ≥2.3 | ||

3 | Elongation at Break(Normal Temperature) | % | ≥450 | |

Elongation at Break(-20ºC) | % | ≥200 | ||

4 | Tearing Strength | KN/m | ≥25 | |

5 | Water Impermeability(30min) | * | 0.3Mpa Impermeability | |

6 | Bend Temperature | ºC | ≤-40 | |

7 | Heating Expansion/Shrinkage | Expansion | mm | ≤2 |

Shrinkage | mm | ≤4 | ||

8 | Hot Air Aging 80ºC x168h | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

9 | Property of Anti Alkali 10% Ca(OH)²x 168h normal temperature | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥80 | ||

10 | Elongation 40%,500x102 | * | No Crack | |

11 | Artificial Aging | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

Appearance of 100% elongation | * | No Crack | ||

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: What is the difference between SBS and APP rolls?

- Compared to the use of SBS waterproofing membrane to use a larger range. But each has its own advantages and disadvantages, according to the local environment and the actual situation of the building in combination with the characteristics of two kinds of coil to choose materials. You have to compare the next, I can only tell you SBS waterproofing membrane prices than APP waterproofing membrane high.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Yes, a waterproofing membrane can be used for underground bunkers. Waterproofing membranes are designed to provide a barrier against water infiltration, which makes them suitable for protecting underground structures such as bunkers from moisture and water damage.

- Q: Can a waterproofing membrane be used for a crawl space?

- Indeed, a crawl space can benefit from the application of a waterproofing membrane. Given their vulnerability to moisture and water infiltration, crawl spaces can experience a range of problems including the growth of mold, structural deterioration, and unpleasant odors. By employing a waterproofing membrane, the infiltration of water and moisture into the crawl space can be effectively impeded. Typically, this membrane is affixed to the walls and floors of the crawl space, forming a secure seal that prevents any water from seeping through. Consequently, this membrane serves as an exceptional remedy for the waterproofing of crawl spaces. Furthermore, certain waterproofing membranes possess antimicrobial properties, thereby further diminishing the likelihood of mold and mildew growth within the crawl space.

- Q: Can waterproofing membranes be used on concrete manholes?

- Indeed, concrete manholes can benefit from the application of waterproofing membranes. These membranes are widely utilized to safeguard structures against water penetration and can be effectively utilized on various surfaces, including concrete. Given that concrete manholes are susceptible to water ingress, which may result in deterioration and structural problems over time, the application of a waterproofing membrane on the concrete surface of the manhole creates a barrier that prevents water intrusion into the structure. This measure serves to lengthen the lifespan of the manhole and guarantee its structural integrity in the long run. Moreover, in addition to providing protection against chemical attacks and other environmental factors, waterproofing membranes further enhance the durability of concrete manholes.

- Q: Does a waterproofing membrane prevent mold and mildew growth?

- Indeed, the growth of mold and mildew can be prevented with the aid of a waterproofing membrane. These fungi flourish in environments characterized by dampness and moisture, but a waterproofing membrane acts as a barrier, thwarting the infiltration of water into the treated surfaces. By keeping moisture at bay, it diminishes the circumstances that facilitate the proliferation of mold and mildew. Nonetheless, it is crucial to acknowledge that while a waterproofing membrane is effective in preventing such growth, it does not ensure absolute protection. Adequate ventilation and consistent upkeep are also imperative in the battle against mold and mildew.

- Q: Can a waterproofing membrane be used for a hospital?

- Yes, a waterproofing membrane can be used for a hospital. Waterproofing membranes are commonly used in construction projects to prevent moisture infiltration and protect the integrity of the building materials. In a hospital setting, where hygiene and infection control are of utmost importance, it is crucial to maintain a dry and clean environment to prevent the growth of mold, mildew, and bacteria. A waterproofing membrane can help to create a barrier against water and moisture, preventing any potential damage to the structure and ensuring a safe and healthy environment for patients, staff, and visitors. Additionally, waterproofing membranes can also be used in specific areas of a hospital, such as operating rooms or laboratories, where the risk of spills or water exposure is higher. Overall, the use of a waterproofing membrane in a hospital can contribute to maintaining a high standard of cleanliness, safety, and durability in the facility.

- Q: Does a waterproofing membrane require any specific cleaning or maintenance procedures?

- To ensure the longevity and effectiveness of a waterproofing membrane, it is necessary to follow specific cleaning and maintenance procedures. Regular cleaning and maintenance are important to prevent the accumulation of debris, dirt, and contaminants that could compromise the membrane's ability to keep water out. The exact procedures for cleaning and maintenance may vary depending on the type of waterproofing membrane used, but there are some general guidelines to follow. Firstly, it is crucial to frequently inspect the membrane for any signs of damage, such as cracks, tears, or deterioration. If any issues are found, they should be addressed promptly to prevent further damage. When it comes to cleaning, it is recommended to use a soft-bristle broom or a leaf blower to remove loose debris or dirt from the membrane surface. It is important to avoid harsh chemicals or abrasive materials that could harm the membrane. Instead, a mild detergent or specialized cleaning solution recommended by the manufacturer should be used. The surface can be gently scrubbed with a soft brush or sponge and thoroughly rinsed with clean water. Additionally, it is vital to keep the surrounding drainage systems clear and free from obstructions. Regular inspection and cleaning of gutters, downspouts, and drains are necessary to ensure proper water flow and prevent potential water damage. Lastly, it is advisable to have the waterproofing membrane professionally inspected and maintained on a regular basis. This will help identify any potential issues early on and ensure that the membrane is functioning optimally. By following these specific cleaning and maintenance procedures, the lifespan of the waterproofing membrane can be prolonged, and its effectiveness in preventing water infiltration can be maintained.

- Q: Can a waterproofing membrane improve energy efficiency?

- Indeed, energy efficiency can be enhanced through the utilization of a waterproofing membrane. By functioning as a barricade against the infiltration of moisture, the waterproofing membrane effectively averts water from permeating the building envelope. Consequently, it maintains the structure's dryness, thus inhibiting the growth of mold and mildew. This is pivotal in the preservation of indoor air quality and the safeguarding of building materials from deterioration. Furthermore, a waterproofing membrane can also offer insulation advantages. Numerous waterproofing membranes are engineered with a substantial thermal resistance, commonly referred to as R-value. This signifies that they can furnish an additional layer of insulation to the edifice, diminishing heat transfer across the walls and roof. By enhancing the thermal performance of the building, a waterproofing membrane facilitates the reduction of the burden placed on heating and cooling systems, ultimately leading to energy savings and improved energy efficiency. Moreover, a waterproofing membrane can contribute to the reduction of air leakage within a building. Air leakage is responsible for a noteworthy amount of energy dissipation, as conditioned air escapes through crevices and fissures in the building envelope. By effectively sealing off these areas, the waterproofing membrane aids in enhancing the airtightness of the building, thereby diminishing energy loss and improving energy efficiency. All in all, a waterproofing membrane assumes a pivotal role in the enhancement of energy efficiency by preventing moisture intrusion, providing supplementary insulation, and diminishing air leakage. Allocating resources towards a top-notch waterproofing system can result in long-term energy savings, improved indoor comfort, and a more sustainable and efficient building.

- Q: Can waterproofing membranes be used on concrete countertops?

- Yes, waterproofing membranes can be used on concrete countertops. These membranes are designed to create a barrier that prevents water from seeping into the concrete, protecting it from damage and increasing its lifespan.

- Q: Can waterproofing membranes be used on roofs?

- Yes, waterproofing membranes can be used on roofs. Waterproofing membranes are specially designed materials that are used to provide a protective layer on roofs to prevent water penetration. These membranes are typically made of materials such as modified bitumen, EPDM, PVC, or TPO, which are highly resistant to water and can effectively seal the roof. They are commonly used in both residential and commercial applications, including flat roofs, low-slope roofs, and even sloped roofs with certain designs. Waterproofing membranes are applied in multiple layers to ensure maximum protection against water damage and can greatly extend the lifespan of a roof by preventing leaks and moisture buildup.

Send your message to us

EPDM Rubber Waterproofing Membrane Underground Leakage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords