EPDM Rubber Waterproof Membrane Width 1.2m Thickness1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

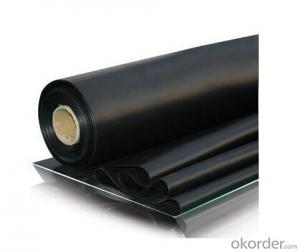

1. Description for EPDM Waterproof Membrane

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-

popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene

rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof

membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization

technology.

2. Features for EPDM Waterproof Membrane

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

3. Application for EPDM Waterproof Membrane

l Roofs, Basement, Toilet

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suit for projects with high requirements in durability, anti-corrosion and deformation

4 Specification for for EPDM Waterproof Membrane

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

5. Image for EPDM Waterproof Membrane

6. FAQ

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane,

Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane,

Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2.What's the main type for EPDM ?

Vulcanized and weldable are the main type .

3.What's the thickness for EPDM ?

1.2mm ,1.5mm ,2.0mm.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Yes, a waterproofing membrane can be used for residential buildings or homes. It is commonly used in basements, bathrooms, and other areas prone to water damage to prevent moisture infiltration and protect the structure from potential water leaks or flooding.

- Q: Can a waterproofing membrane be painted or covered with a protective layer?

- Yes, a waterproofing membrane can be painted or covered with a protective layer. However, it is important to choose the right type of paint or protective layer that is specifically designed for use with waterproofing membranes. This ensures that the integrity of the membrane is not compromised and that it continues to provide effective protection against water damage. It is also important to follow the manufacturer's guidelines and recommendations when applying paint or a protective layer to the membrane. This may include proper surface preparation, application techniques, and maintenance instructions. By following these guidelines, the waterproofing membrane can be painted or covered with a protective layer without compromising its effectiveness.

- Q: Can a waterproofing membrane be used for a green roof system?

- Indeed, a green roof system can utilize a waterproofing membrane. In truth, a top-notch waterproofing membrane is a vital element of a green roof system. These roofs are specifically designed to facilitate the growth of vegetation and necessitate a strong and dependable waterproofing barrier to deter water leakage and safeguard the underlying structure against moisture damage. A waterproofing membrane functions as a safeguarding layer, effectively sealing the roof and preventing water infiltration into the building. Moreover, the membrane aids in retaining water within the green roof system, ensuring that the plants receive an ample supply of water. Consequently, the integration of a waterproofing membrane into a green roof system is indispensable for its triumph and durability.

- Q: Are waterproofing membranes suitable for commercial applications?

- Yes, waterproofing membranes are suitable for commercial applications. Waterproofing membranes are specifically designed to protect buildings, structures, and surfaces from water infiltration, moisture damage, and other related problems. They are often used in various commercial applications such as roofs, basements, underground parking garages, and exterior walls. Commercial buildings are exposed to a wide range of weather conditions and water sources, including rain, snow, and groundwater. Waterproofing membranes provide a reliable barrier against water penetration, preventing costly water damage and ensuring the longevity of the building. Additionally, they can also act as a vapor barrier, preventing moisture buildup and condensation within the building envelope, which can lead to mold growth and structural deterioration. Waterproofing membranes are available in various materials, such as bitumen, modified bitumen, EPDM, PVC, and TPO. These materials offer different advantages and characteristics, allowing for flexibility in choosing the most suitable option for specific commercial applications. They can be applied as a liquid coating, sheets, or panels, providing versatility in installation methods to accommodate different building designs and requirements. Furthermore, waterproofing membranes can be customized to meet specific commercial needs, such as fire resistance, UV protection, and durability. This makes them effective in protecting commercial properties that may be subjected to heavy foot traffic, mechanical equipment, or other potential sources of damage. In summary, waterproofing membranes are a highly suitable solution for commercial applications. They offer reliable protection against water infiltration, moisture damage, and other related problems, ensuring the longevity and structural integrity of commercial buildings. Their versatility, customization options, and ability to withstand various weather conditions make them an excellent choice for commercial waterproofing needs.

- Q: How thick should a waterproofing membrane be?

- The thickness of a waterproofing membrane is influenced by various factors, including the type of membrane, specific application, and desired level of protection. Typically, the thickness of a waterproofing membrane can range from 0.5mm to 4mm. For waterproofing applications below ground, like basements or foundations, it is generally recommended to use a thicker membrane to provide better defense against water infiltration and potential hydrostatic pressure. In these cases, a membrane thickness of approximately 2mm to 4mm is commonly utilized. Conversely, for above-ground applications such as roofs or balconies, a thinner membrane is often sufficient. A thickness of 0.5mm to 2mm is typically satisfactory in creating a reliable waterproofing barrier. It is important to understand that the thickness alone does not solely determine the effectiveness of a waterproofing membrane. Other factors, such as the material's composition, quality, and installation techniques, also significantly contribute to ensuring a long-lasting and efficient waterproofing solution. Therefore, consulting with a professional waterproofing expert or manufacturer is essential in order to determine the appropriate thickness based on the specific requirements and conditions of the project.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Yes, a waterproofing membrane can definitely be used in government or municipal projects. In fact, it is often a crucial component in the construction or renovation of various infrastructure projects such as roads, bridges, tunnels, and buildings. Waterproofing membranes help to prevent water infiltration, which can cause damage to the structure and compromise its integrity. By using a waterproofing membrane, government and municipal projects can ensure the longevity and durability of their infrastructure, reducing the need for costly repairs or replacements in the future. Additionally, waterproofing membranes can also contribute to energy efficiency by preventing moisture intrusion, thus reducing the potential for mold growth and improving insulation properties. Overall, the use of a waterproofing membrane in government or municipal projects is highly recommended to enhance the lifespan and functionality of the infrastructure.

- Q: Is a waterproofing membrane resistant to saltwater or salt damage?

- Typically, a waterproofing membrane resists saltwater or salt damage. Its purpose is to create a barrier against water and moisture, making it suitable for use in marine environments or coastal areas. These membranes are made from materials that can withstand the corrosive effects of saltwater or salt. To ensure their resistance to saltwater or salt damage, proper preparation and sealing techniques are employed during installation. However, it is important to note that the level of resistance may vary depending on the type and quality of the membrane. Therefore, it is advisable to consult with a professional or the manufacturer to choose the appropriate membrane for the specific application and environment.

- Q: Can a waterproofing membrane be used in conjunction with flooring materials?

- Yes, a waterproofing membrane can be used in conjunction with flooring materials. In fact, it is often recommended to use a waterproofing membrane when installing certain types of flooring, such as in wet areas like bathrooms, kitchens, or basements. A waterproofing membrane acts as a barrier against moisture, preventing water from seeping through and damaging the flooring material or the subfloor. It helps to protect the flooring from leaks, spills, or even excessive moisture in the air. By using a waterproofing membrane, you can ensure the longevity and durability of your flooring, while also maintaining a waterproof and moisture-resistant environment.

- Q: How to use self-adhesive waterproofing membrane?

- Construction Technology of Double - sided Self - adhesive Waterproof Coil First, the empty shop self - adhesive waterproofing membrane (mainly applicable to the basement floor and other suitable for the empty parts of the waterproofing works. Construction process: grass-roots treatment - → node strengthening treatment - → empty sheet - → long, short side lap bond - → quality acceptance 1) grass-roots treatment: grass-roots should be smooth, solid, no clear water, the grass-roots protrusions clean. 2) node to strengthen the processing: the node at the regulatory requirements to strengthen the treatment. 3) empty shop coil: coil length, short side of the overlap width of not less than 60mm. 4) long, short side lap bond: the length of the coil, short lap edge of the isolation film removed, 5) Adhesive on polystyrene board protection

- Q: What is the difference between PET waterproofing membrane and BAC waterproofing membrane? What is the commonality? Is BAC a PET?

- BAC is not equal to PET, carcass material is not the same, and BAC also fiberglass tire coil.

Send your message to us

EPDM Rubber Waterproof Membrane Width 1.2m Thickness1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords