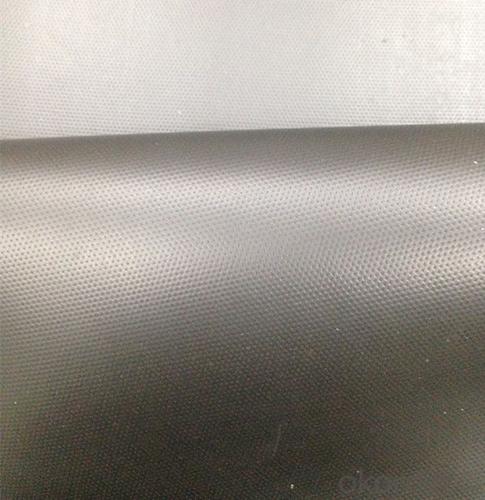

Vulcanized EPDM Waterproof Membrane Width1.2m Thickness 1.2mm, 1.5mm, 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos:

- Q: Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- A waterproofing membrane works well in areas where the groundwater levels are high. Its purpose is to stop water from getting in, making it an effective barrier against groundwater. These membranes are usually made from materials like bitumen, PVC, or EPDM, which are extremely resistant to water and can handle a lot of pressure from below. They are built to create a tight seal, keeping water out of buildings or underground areas. Because of this, a waterproofing membrane is the perfect choice for places with high groundwater levels. It can successfully guard against water infiltration and the potential harm it could cause to structures or infrastructure.

- Q: Can a waterproofing membrane be used in high-traffic areas, such as decks or balconies?

- Yes, a waterproofing membrane can be used in high-traffic areas such as decks or balconies. Waterproofing membranes are designed to provide protection against water damage and can withstand regular foot traffic. They are durable and can effectively prevent water penetration, making them suitable for use in areas that experience heavy use.

- Q: Can a waterproofing membrane be used for parking garage ramps and driveways?

- Yes, a waterproofing membrane can be used for parking garage ramps and driveways. These areas are often exposed to water, moisture, and other environmental elements that can cause damage to the structure over time. By applying a waterproofing membrane, it creates a barrier that prevents water penetration and protects the underlying concrete or asphalt from deterioration. This helps to extend the lifespan of the ramps and driveways, reduce maintenance costs, and enhance overall durability. Additionally, the use of a waterproofing membrane can also prevent water from seeping into the underground parking areas, preventing potential water damage and maintaining a safe and dry environment for vehicles and pedestrians.

- Q: Can a waterproofing membrane be used on precast concrete block surfaces?

- Yes, a waterproofing membrane can be used on precast concrete block surfaces. It helps to prevent water penetration and protects the structure from potential damage caused by moisture.

- Q: Are waterproofing membranes resistant to battery acid?

- Waterproofing membranes are typically not specifically designed to be resistant to battery acid. The purpose of waterproofing membranes is to provide a barrier against water and moisture, and they are typically made of materials such as bitumen, rubber, or modified asphalt. While these materials may have some level of resistance to certain acids, they are not typically designed to withstand the corrosive properties of battery acid. Battery acid, which is typically sulfuric acid, can cause significant damage to many materials, including waterproofing membranes. If you are working with battery acid or have a situation where exposure to battery acid is a concern, it is recommended to use materials specifically designed to resist the corrosive effects of battery acid or consult with a professional for appropriate solutions.

- Q: Can waterproofing membranes be used on mechanical rooms?

- Yes, waterproofing membranes can be used on mechanical rooms. These membranes are designed to provide a protective barrier against water infiltration, making them suitable for use in areas prone to moisture or water exposure, such as mechanical rooms.

- Q: Can a waterproofing membrane be used on precast concrete block surfaces?

- Yes, a waterproofing membrane can be used on precast concrete block surfaces. It helps to prevent water penetration and protects the structure from potential damage caused by moisture.

- Q: Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. However, it is important to consider the specific needs and requirements of the building. The use of a waterproofing membrane should be carefully assessed and integrated into the building's preservation and conservation plans to ensure compatibility with its historic fabric and materials. Professional advice and expertise should be sought to ensure the appropriate selection and installation of the waterproofing membrane without compromising the building's historic integrity.

- Q: Basement SBS Waterproof Coil Division I and II type What is the difference? How is the site identified?

- Type I low temperature flexibility is -20 degrees, pulling force of 500N / 5cm, elongation of 30%. Type II low temperature is -25 degrees, tension of 800N / 5cm, elongation of 40%. The appearance of the general can not distinguish, you can take the sample to the laboratory to be a tensile test on it.

- Q: Can waterproofing membranes be used on terraces?

- Yes, waterproofing membranes can be used on terraces to prevent water penetration and protect the underlying structure from moisture damage.

Send your message to us

Vulcanized EPDM Waterproof Membrane Width1.2m Thickness 1.2mm, 1.5mm, 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords