EPDM Waterproofing Rubber Membrane 1.5mm 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction for EPDM Waterproof Membrane:

The product uses the technology of internationally advanced level-cold feed extruder continuous vulcanization, chooses imported epdm and accessories with high quality. The production is of well quality according to the national standards.

This product has the high elasticity and high elongation and high tear strength and excellent low temperature performance and water resistance, ozone resistance, aging resistance performance.

2. Product Technical Index for EPDM Waterproof Membrane:

Item | Index | |

Tensile strength (N/cm) | normal temperature≥ | 7.5 |

60°C | 2.3 | |

Elongation at break (%) | normal temperature≥ | 450 |

’-20°C | 200 | |

Tear Resistance,KN/m≥ | 25 | |

waterproofness, 30min no permeation | 0.3Mpa | |

Low temperature bending °C≤ | -40 | |

Heating expansion amount,mm | extension< | 2 |

shrinkage< | 4 | |

3. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

4. Note of Use:

Don't spread on the surface of the frozen base for the coil;

Don't construct on the pollution and moisture content on the high side at the grass-roots level;

Adhesive coil packaging and isolation of paper can only removed in front of the shop post and posting ;

When sealant isn't used up, it need to tighten the container seal in time

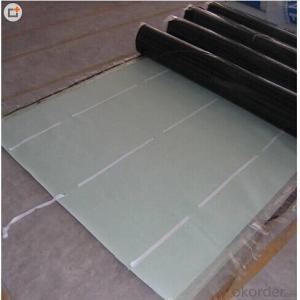

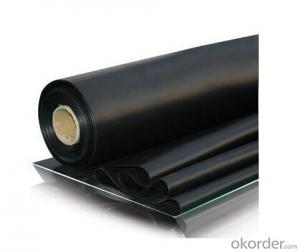

5. Some photos:

- Q: Coil waterproof roofing requirements

- 2, grass-roots moisture content of less than 9%, knife scratch marks white,

- Q: How does a waterproofing membrane handle exposure to UV radiation?

- A waterproofing membrane is specifically designed to handle exposure to UV radiation, which is a common environmental factor that can deteriorate and degrade materials over time. To combat the damaging effects of UV radiation, waterproofing membranes are typically manufactured with UV stabilizers and additives that help to protect the membrane from the harmful effects of the sun. These UV stabilizers act as a barrier, absorbing or reflecting the UV rays and preventing them from penetrating the membrane. Additionally, some waterproofing membranes may have additional protective layers or coatings that enhance their resistance to UV radiation. Overall, the presence of UV stabilizers and protective layers in waterproofing membranes ensures that they can withstand prolonged exposure to UV radiation without compromising their performance or integrity.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Yes, a waterproofing membrane does require specific cleaning methods. It is important to clean the membrane regularly to maintain its effectiveness and longevity. The specific cleaning methods will depend on the type of waterproofing membrane being used, as different materials may have different cleaning requirements. In general, it is recommended to use gentle cleaning solutions and tools, such as a soft brush and mild detergent, to clean the membrane. It is important to avoid using harsh chemicals or abrasive materials that could damage the membrane. Additionally, regular inspection of the membrane for any signs of damage or debris accumulation is essential, as addressing these issues promptly can help prevent further damage and ensure the membrane continues to provide effective waterproofing. Consulting the manufacturer's guidelines and recommendations for cleaning and maintenance is highly recommended to ensure proper care of the waterproofing membrane.

- Q: Can a waterproofing membrane be covered or concealed by other finishes or materials?

- Indeed, other finishes or materials have the capability to cover or mask a waterproofing membrane. In fact, this practice is widely employed in construction projects. The primary purpose of a waterproofing membrane is to establish a barrier against water infiltration and safeguard the underlying structure. Prior to the application of other finishes or materials, it is typically installed on surfaces like roofs, foundations, or walls. Concealing the waterproofing membrane with other finishes or materials serves two key objectives. Firstly, it enhances the aesthetics of the structure. Whether it is a roof, bathroom, or basement, hiding the waterproofing membrane allows for the incorporation of more visually pleasing finishes such as tiles, paints, or decorative elements. Secondly, covering the waterproofing membrane provides an additional layer of protection. While the membrane itself is designed to be water-resistant, it may still be susceptible to damage from UV rays, foot traffic, or general wear and tear. By adding other finishes or materials on top, such as protective coatings, tiles, or concrete, the waterproofing membrane is shielded from potential harm, extending its lifespan and effectiveness. However, it is crucial to note that proper installation and compatibility between the waterproofing membrane and the covering materials are of utmost importance. The covering materials should not compromise the integrity of the membrane or create any weak points. Additionally, any penetrations or joints in the covering materials must be meticulously sealed to maintain the effectiveness of the waterproofing system. Therefore, while it is possible to cover or conceal a waterproofing membrane with other finishes or materials, it is essential to adhere to manufacturer guidelines and seek professional advice to ensure the overall integrity and performance of the waterproofing system.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. They are designed to protect against moisture and other environmental factors, including saltwater. The membranes are specifically engineered to provide a barrier that prevents water and salts from infiltrating and causing damage to underlying structures.

- Q: Can a waterproofing membrane be used for below-grade parking structures?

- Yes, a waterproofing membrane can be used for below-grade parking structures. Waterproofing membranes are commonly used in construction to prevent the ingress of water and protect structures from water damage. In the case of below-grade parking structures, which are underground or partially underground, there is a higher risk of water infiltration due to the surrounding soil and groundwater. Waterproofing membranes are applied to the exterior surfaces of the structure, creating a barrier that prevents water from seeping through the walls and floors. These membranes are typically made of materials such as bitumen, rubberized asphalt, PVC, or polyurethane, which are highly resistant to water penetration. Additionally, some membranes may also have additional properties like crack-bridging capabilities or protection against chemicals or gases. It is important to consult with a qualified engineer or waterproofing specialist to determine the most suitable membrane for a specific below-grade parking structure, taking into consideration factors such as soil conditions, hydrostatic pressure, and local building codes.

- Q: Can a waterproofing membrane be used for podium decks or plaza areas?

- Podium decks or plaza areas can benefit from the application of a waterproofing membrane. It is highly recommended to utilize this protective layer in order to safeguard the underlying structure from water-related harm. Given their exposure to the elements, podium decks and plaza areas are susceptible to water infiltration. By implementing a waterproofing membrane, water seepage into the lower layers can be effectively prevented, thus ensuring the long-lasting durability and structural integrity of the deck or plaza. Furthermore, this waterproofing membrane is also capable of shielding spaces beneath the deck or plaza, such as basements or parking garages, from potential water damage. Therefore, it is crucial to select a top-notch waterproofing membrane specifically designed for outdoor purposes, and to carefully adhere to the manufacturer's instructions regarding proper installation and maintenance.

- Q: Can a waterproofing membrane be used on swimming pools?

- Yes, a waterproofing membrane can be used on swimming pools. In fact, it is a common and effective method for ensuring the pool remains watertight. Waterproofing membranes are typically made of materials such as PVC or rubber and are specifically designed to prevent water from seeping through the walls or floor of the pool. These membranes are applied as a thin layer or sheet over the pool's surfaces, creating a barrier that keeps water contained within the pool. This helps to minimize the risk of leaks and water damage, ensuring the longevity and functionality of the swimming pool.

- Q: Can a waterproofing membrane be used for underground parking structures?

- Yes, a waterproofing membrane can be used for underground parking structures. Waterproofing membranes are commonly used in construction to prevent water infiltration and protect the structure from moisture damage. In underground parking structures, where there is a higher risk of water seepage due to the location below ground level, a waterproofing membrane can be applied to the walls, floors, and ceilings to create a barrier against water intrusion and ensure the longevity and integrity of the structure.

- Q: Are waterproofing membranes resistant to hydrocarbons?

- Yes, waterproofing membranes are generally resistant to hydrocarbons. Waterproofing membranes are designed to provide a barrier against water penetration and are often made from materials such as bitumen, PVC, TPO, or EPDM. These materials have inherent resistance to hydrocarbons and can withstand exposure to various types of hydrocarbon-based substances such as oil, gasoline, diesel, and other petroleum-based products. This resistance ensures that the waterproofing membrane remains intact and effective in preventing water infiltration even when exposed to hydrocarbons. However, it is important to note that the specific resistance of a waterproofing membrane to hydrocarbons may vary depending on the material used and its quality. Therefore, it is always recommended to consult the manufacturer's specifications and guidelines to ensure the appropriate selection and installation of a waterproofing membrane for specific hydrocarbon-resistant requirements.

Send your message to us

EPDM Waterproofing Rubber Membrane 1.5mm 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords