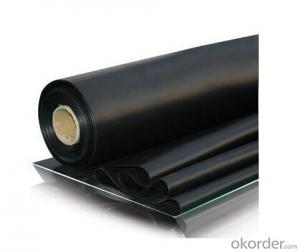

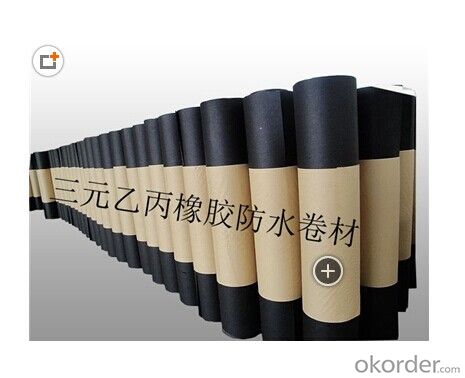

EPDM Rubber Vulcanization Waterproof Membrane 1.2mm/1.5mm/2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

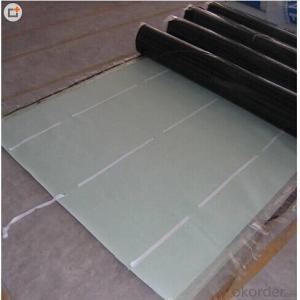

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Uses for EPDM Waterproof Membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Data for EPDM Waterproof Membrane

Item | value | ||

JL1 | JF1 | ||

Tensile Strength (Mpa) | normal tamperature | 7.5 | 4.0 |

60°C ≥ | 2.3 | 0.8 | |

Elongation at break (%) | normal tamperature ≥ | 450 | 450 |

-20°C ≥ | 200 | 200 | |

Tear Resistance (N) | ≥ | 25 | 18 |

Water impermeability | 30mm | 0.3Mpa | 0.3Mpa |

Cold bending | (°C) ≤ | -40 | -30 |

Heating Shrinking rate | extand << span=""> | 2 | 2 |

shrink << span=""> | 4 | 4 | |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Are waterproofing membranes resistant to punctures?

- Yes, waterproofing membranes are designed to be resistant to punctures. They are typically made from durable materials that can withstand external forces without tearing or puncturing, ensuring long-lasting protection against water intrusion.

- Q: Can a waterproofing membrane be used for storage tanks or containment areas?

- Storage tanks or containment areas can utilize a waterproofing membrane to prevent water or liquid penetration. These membranes serve as a barrier against such infiltrations and are therefore ideal for containment purposes. Rubber, PVC, or bitumen are commonly used materials for these membranes due to their water-resistant properties. They can be applied either internally or externally to storage tanks or containment areas to safeguard against leaks and moisture-related deterioration. Moreover, the use of waterproofing membranes aids in preventing the development of mold or mildew, thereby ensuring a secure and hygienic environment for stored materials or liquids.

- Q: Does a waterproofing membrane require any special tools for installation?

- Typically, a few special tools are necessary for installing a waterproofing membrane. These tools might include a utility knife or scissors for cutting the membrane to the right size, a trowel or notched trowel for spreading the adhesive or mortar, a roller or squeegee to ensure proper adhesion, a brush or sprayer for applying primers or sealants, and a heat gun or torch for activating self-adhesive membranes. Depending on the specific method of installation and type of membrane, other tools like a nail gun, stapler, or specialized fasteners may also be needed. To determine the exact tools required for a particular waterproofing membrane, it is crucial to refer to the manufacturer's installation guidelines and recommendations.

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Tunnels with subway systems can indeed benefit from the use of a waterproofing membrane. It is strongly advised to incorporate this protective layer into subway tunnel construction to prevent water infiltration and potential harm to the structure and electrical systems. The waterproofing membrane acts as a barrier, effectively excluding water and safeguarding the tunnel against issues caused by moisture, such as corrosion, mold, and deterioration. It is crucial to select a waterproofing membrane that is specially designed for tunnel use and capable of withstanding the unique challenges and conditions of subway systems, including heavy traffic loads, vibrations, and exposure to chemicals. Moreover, it is essential to ensure the installation of the waterproofing membrane is carried out by experienced professionals who adhere to the appropriate guidelines and specifications, guaranteeing its effectiveness and durability.

- Q: Can a waterproofing membrane be used in conjunction with energy-efficient building designs?

- Yes, a waterproofing membrane can be used in conjunction with energy-efficient building designs. In fact, incorporating a waterproofing membrane into the construction of an energy-efficient building can provide several benefits. Firstly, a waterproofing membrane helps to protect the building envelope from water infiltration, which is critical for maintaining the integrity and longevity of the structure. By preventing water damage, the building can avoid costly repairs and potential energy losses caused by moisture intrusion. Additionally, a well-designed waterproofing system can contribute to the energy efficiency of the building by reducing the need for mechanical heating and cooling. By preventing moisture from entering the building envelope, the waterproofing membrane helps to maintain a consistent indoor temperature, reducing the load on HVAC systems and improving energy efficiency. Furthermore, certain types of waterproofing membranes, such as those with reflective or heat-resistant properties, can also contribute to energy savings by reducing heat transfer through the building envelope. These membranes reflect solar radiation, reducing the amount of heat absorbed by the building, and thus decreasing the demand for cooling. Lastly, waterproofing membranes can be integrated with other energy-efficient building components, such as green roofs or rainwater harvesting systems. These systems can help to further reduce energy consumption by providing insulation, reducing stormwater runoff, and promoting sustainable water management practices. Overall, incorporating a waterproofing membrane into an energy-efficient building design can enhance both the durability and energy performance of the structure. It offers protection against water damage, reduces the load on mechanical systems, and can be integrated with other sustainable features, making it a valuable component of energy-efficient building designs.

- Q: Can a waterproofing membrane be used on vinyl surfaces?

- Yes, a waterproofing membrane can be used on vinyl surfaces. The membrane serves as a protective layer that prevents water from penetrating and damaging the vinyl material.

- Q: Can a waterproofing membrane be used in swimming pools or water features?

- Yes, a waterproofing membrane can be used in swimming pools or water features. Waterproofing membranes are specifically designed to prevent water leakage and can effectively seal and protect the surfaces of pools and water features from water damage.

- Q: Can waterproofing membranes be used on concrete surfaces?

- Concrete surfaces can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to create a barrier against water penetration. They are often employed on concrete surfaces to safeguard them against water damage. Typically, these membranes are composed of rubber, PVC, or bitumen and can be applied to the concrete surface either in a liquid or sheet form. Once applied, the membrane forms a strong and continuous waterproof layer that effectively prevents water from seeping into the concrete. This proves to be particularly advantageous in areas that frequently come into contact with water, such as basements, bathrooms, or outdoor concrete structures. By preventing water-related issues such as cracking, spalling, or mold growth, waterproofing membranes effectively prolong the lifespan of concrete surfaces.

- Q: Does a waterproofing membrane require a topcoat or sealer?

- Yes, a waterproofing membrane typically requires a topcoat or sealer in order to provide additional protection and enhance its effectiveness. While the membrane itself is designed to prevent water penetration, applying a topcoat or sealer can further reinforce its waterproofing capabilities and extend its lifespan. The topcoat or sealer acts as an extra layer of defense against moisture, UV rays, and other potential sources of damage. Additionally, it can help seal any small cracks or imperfections in the membrane, ensuring a tighter seal and reducing the risk of water infiltration. Therefore, while a waterproofing membrane can offer some level of protection on its own, the addition of a topcoat or sealer is generally recommended for optimal performance and longevity.

- Q: Can a waterproofing membrane be used on interior walls?

- Yes, a waterproofing membrane can be used on interior walls. Waterproofing membranes are designed to create a barrier against moisture, preventing water from penetrating the surface and causing damage. While they are commonly used on exterior walls to protect against rain and groundwater, they can also be used on interior walls in areas that are prone to moisture, such as bathrooms, kitchens, or basements. By applying a waterproofing membrane, you can effectively protect the interior walls from water damage, mold growth, and other moisture-related issues. It is important to note that the specific type of waterproofing membrane and the proper installation technique should be determined based on the specific needs and conditions of the interior walls. Consulting with a professional or following manufacturer guidelines is recommended to ensure proper application and long-lasting protection.

Send your message to us

EPDM Rubber Vulcanization Waterproof Membrane 1.2mm/1.5mm/2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords