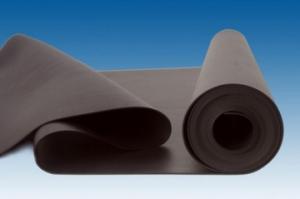

EPDM Rubber Waterproof Membrane Used for Roof and Under Basement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Feature for EPDM Waterproof Membrane:

a. UV resistant and anti-corrosion

b. High tensile strength and good elongation.

c. Easy installation, solid joint, and no environmental pollution

d. Good rooting penetration resistance

e. Service life up to 50 years

2. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

Width | 1m to 4m |

Length | 20m |

Model | EPDM, EPDM with fabric |

3. Product Application:

1. Roofs, Basement, Toilet

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suit for projects with high requirements in durability, anti-corrosion and deformation.

4. Some photos:

RFQ:

1) What's your package?

one roll with one woven bag, then 15-20rolls in one pallet

2) What's your payment terms?

T/T or L/C at sight

3) What's your delivery time?

Within one week against advance payment received

- Q: Are waterproofing membranes suitable for wastewater treatment plants?

- Yes, waterproofing membranes are suitable for wastewater treatment plants. Wastewater treatment plants deal with the treatment and processing of wastewater, which contains a variety of chemicals, contaminants, and bacteria. These substances can be highly corrosive and can cause damage to the infrastructure of the plant if not properly protected. Waterproofing membranes provide an effective barrier against water and chemical penetration, preventing leaks, seepage, and corrosion. They can be applied to various areas of the plant, including tanks, basins, pipelines, and concrete structures. Additionally, waterproofing membranes are durable, long-lasting, and can withstand the harsh conditions and chemicals present in wastewater treatment plants. Therefore, using waterproofing membranes in wastewater treatment plants is a recommended practice to ensure the integrity, longevity, and efficiency of the infrastructure.

- Q: Can a waterproofing membrane be used for industrial facilities and factories?

- Yes, a waterproofing membrane can be used for industrial facilities and factories. Industrial facilities and factories often have areas that are exposed to moisture, such as basements, rooftops, and storage areas. These areas are prone to water leakage and damage, which can result in costly repairs and downtime. A waterproofing membrane is a highly effective solution for protecting these areas from water infiltration. It is a flexible and durable barrier that is applied to surfaces to prevent water from penetrating through. Waterproofing membranes are designed to withstand various environmental conditions, including temperature changes, UV exposure, and chemical exposure, making them suitable for industrial settings. By installing a waterproofing membrane, industrial facilities and factories can prevent water damage, mold growth, and structural deterioration caused by moisture. This helps to maintain a safe and functional environment for workers and equipment, while also ensuring the longevity of the facility. Additionally, a waterproofing membrane can help to improve energy efficiency by reducing heat loss through insulation and preventing water-related damage to HVAC systems. Overall, using a waterproofing membrane in industrial facilities and factories is a practical and cost-effective solution for ensuring the protection and longevity of the facility.

- Q: Can a waterproofing membrane be used for a swimming pool liner installation?

- Yes, a waterproofing membrane can be used for a swimming pool liner installation. Waterproofing membranes are designed to create a waterproof barrier and prevent water from seeping through. This makes them an ideal choice for lining swimming pools as they can effectively protect the pool structure from water damage.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Yes, a waterproofing membrane can be used on precast metal surfaces. The membrane acts as a protective barrier, preventing water from seeping through the metal and causing damage. It helps to maintain the integrity and longevity of the precast metal surfaces by keeping them dry and free from moisture-related issues.

- Q: What is the difference between polymer waterproofing membrane and cross film waterproofing membrane?

- he strong cross-over film of the product is a high-strength HDPE film formed by the cross-laminating process. The film and the like have the same vertical and transverse elongation ratio. The coil does not send deformation, more beautiful and waterproof reliable.

- Q: Can a waterproofing membrane be tested for quality or performance?

- Indeed, it is possible to assess the quality and performance of a waterproofing membrane through various tests. Effectiveness and durability can be evaluated by conducting several tests. One such test is the water penetration test, which involves subjecting the membrane to a specific level of water pressure to determine if any water can pass through it. Another evaluation is the adhesion test, which assesses the strength of the bond between the membrane and the substrate. Furthermore, tests can be carried out to gauge the membrane's resistance to chemicals, UV radiation, temperature fluctuations, and physical stress. These tests contribute to determining if the membrane meets the required standards and can effectively function under diverse conditions.

- Q: Are waterproofing membranes resistant to soil chemicals?

- Waterproofing membranes are commonly resistant to soil chemicals. These membranes are created to act as a barrier against water and moisture, and they are often manufactured using materials that can resist various chemicals found in soil. This resistance aids in safeguarding the membrane from deterioration or harm caused by exposure to soil chemicals. Moreover, waterproofing membranes are frequently subjected to testing and certification to ensure compliance with industry standards and regulations, including resistance to soil chemicals. Nevertheless, it is important to acknowledge that the degree of resistance may vary depending on the particular type and quality of the waterproofing membrane employed. Thus, it is crucial to select the appropriate membrane that is specifically designed to endure the soil conditions and chemicals present in the project area. Seeking advice from a professional or the manufacturer can offer further guidance on the most suitable waterproofing membrane for a specific application.

- Q: Can a waterproofing membrane be used in residential construction?

- Residential construction can indeed utilize a waterproofing membrane. These membranes find common usage in different parts of a residential property, such as roofs, basements, bathrooms, and foundations. Their purpose is to prevent water from penetrating and causing damage due to moisture. By opting for a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks. This is crucial because such leaks can result in mold growth, structural deterioration, and other costly problems. The market offers a variety of waterproofing membranes, such as sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can assist in determining the most suitable waterproofing membrane for a particular residential construction project.

- Q: Can waterproofing membranes be used on wood surfaces?

- Waterproofing membranes have the capability to be utilized on wood surfaces. These membranes are highly adaptable and can be applied to various materials, including wood. Their main purpose is to establish a safeguarding barrier that hinders water infiltration, thus preventing moisture-related harm such as decay, distortion, or the growth of mold. By correctly applying waterproofing membranes, wood surfaces can be effectively sealed, rendering them impervious to water absorption and enhancing their longevity and robustness. It is crucial to select a waterproofing membrane that is specially developed for wood applications and adhere to the manufacturer's guidelines for appropriate application and upkeep.

- Q: Are there any special tools required for installing a waterproofing membrane?

- Installing a waterproofing membrane necessitates the use of various specialized tools. The specific tools required can differ depending on the type of membrane being installed, though some commonly used tools include a trowel or brush to apply the membrane, a utility knife to cut the membrane to the appropriate size, a roller for ensuring proper adhesion, and a heat gun to activate any adhesive properties of the membrane. In addition, other tools such as a measuring tape, level, and caulking gun may be required to ensure accurate installation. To guarantee that the correct tools are utilized for the specific membrane being installed, it is essential to refer to the manufacturer's instructions and recommendations.

Send your message to us

EPDM Rubber Waterproof Membrane Used for Roof and Under Basement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords