Geogrid Under Concrete

Geogrid Under Concrete Related Searches

Geogrid Under Pavers Laying Geogrid Geogrid Construction Geogrid On Slope Geogrid For Road Construction Geogrid With Geotextile Geogrid Road Construction Geogrid Pavement Geogrid For Roads Geogrid Installation Geogrid Paving Geogrid Near Me Geogrid For Gravel Roads Composite Geogrid Asphalt Geogrid Geogrid For Driveways Geogrid For Gravel Geogrid In Retaining Walls Gravel Geogrid Geogrid Wall Construction Geogrid For Driveway Geogrid Walls Geogrid Blocks Extruded Geogrid Synthetic Geogrid Forming Concrete Geogrid Layer Geogrid Machine Bonded Geogrid Geogrid For Soil StabilizationGeogrid Under Concrete Supplier & Manufacturer from China

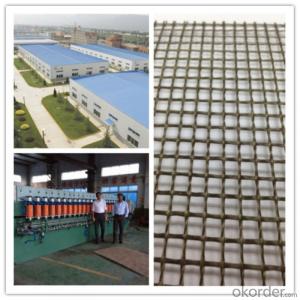

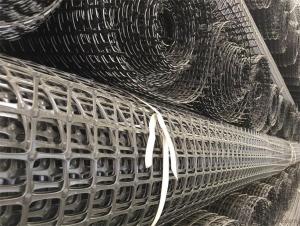

Geogrid Under Concrete is a type of geosynthetic material used to reinforce and stabilize soil structures, commonly employed in civil engineering projects. This product is specifically designed to be placed beneath concrete surfaces, enhancing the load-bearing capacity and durability of the construction. Geogrid Under Concrete is utilized in various applications, such as road construction, bridge abutments, and retaining walls, providing a cost-effective and efficient solution for improving the structural integrity of these projects. By incorporating Geogrid Under Concrete into these applications, engineers can achieve increased stability, reduced maintenance costs, and prolonged service life for the infrastructure.Okorder.com is a reputable wholesale supplier of Geogrid Under Concrete, offering a vast inventory of high-quality products to meet the demands of various construction projects. With a commitment to customer satisfaction and a focus on providing reliable solutions, Okorder.com ensures that their Geogrid Under Concrete products are manufactured to the highest standards, ensuring optimal performance and longevity in the field. By partnering with Okorder.com, contractors and engineers can access the Geogrid Under Concrete they need to successfully complete their projects, backed by the support and expertise of a trusted supplier.

Hot Products