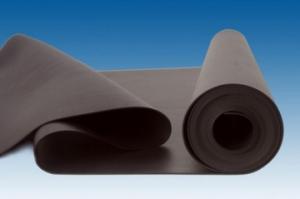

EPDM Rubber Waterproof Membrane for Roofing, Basement, Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3600 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vulcanized / Weldable EPDM Rubber Waterproof Membrane

EPDM rubber waterproof membrane for roof and basement

Width: 1.2m.2m.3m,4m

Length: 20m

Thickness: 1.2mm/1.5mm/2.0mm

Type: Vulcanized / Weldable

Profile of EPDM Waterproof Membrane:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Advantages of EPDM Waterproof Membrane:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications of EPDM Waterproof Membrane:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building

waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially

to the keystone waterproofing projects which is durability, high corrosion resistance and easy

deformation.

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications of EPDM Waterproof Membrane:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos of EPDM Waterproof Membrane:

- Q: Can a waterproofing membrane be used on precast brick block surfaces?

- Precast brick block surfaces can indeed benefit from the application of a waterproofing membrane. Such a membrane serves as a protective shield, safeguarding the bricks against water infiltration, which could otherwise lead to undesirable consequences like cracks, efflorescence, or the growth of mold. It is crucial to select a waterproofing membrane explicitly designed for masonry surfaces, as these membranes are specially formulated to adhere perfectly to the distinct properties of brick and block materials. Moreover, to guarantee the membrane's effectiveness, it is essential to adhere to proper surface preparation and application techniques.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Yes, a waterproofing membrane can be used for tunnels or subway systems. It is a common practice to use waterproofing membranes in underground structures to prevent water infiltration and protect the structural integrity of the tunnels or subway systems. These membranes are designed to provide a barrier against water, ensuring the safety and longevity of the underground infrastructure.

- Q: Can a waterproofing membrane be used on swimming pools?

- Yes, a waterproofing membrane can be used on swimming pools. In fact, it is a common and effective method for ensuring the pool remains watertight. Waterproofing membranes are typically made of materials such as PVC or rubber and are specifically designed to prevent water from seeping through the walls or floor of the pool. These membranes are applied as a thin layer or sheet over the pool's surfaces, creating a barrier that keeps water contained within the pool. This helps to minimize the risk of leaks and water damage, ensuring the longevity and functionality of the swimming pool.

- Q: Can a waterproofing membrane be used for wastewater treatment plants?

- Indeed, wastewater treatment plants can make use of a waterproofing membrane. Waterproofing membranes are frequently employed in various construction undertakings, including wastewater treatment plants, to establish a barrier against the infiltration of water. These membranes are specifically designed to prevent water from permeating the structure, which is of utmost importance for wastewater treatment plants due to their handling of considerable water volumes. Wastewater treatment plants constantly face exposure to water and high levels of humidity, which may result in moisture-related harm and structural degradation. By incorporating a waterproofing membrane, the facility can effectively avert water penetration, thereby ensuring the soundness and longevity of the structure. Furthermore, wastewater treatment plants commonly contain diverse corrosive chemicals and substances that can cause damage to the structure over time. Waterproofing membranes can serve as a protective layer, effectively shielding the building materials against these chemicals and deterring structural problems. Various types of waterproofing membranes are available, such as sheet membranes, liquid membranes, and cementitious membranes. The selection of a suitable membrane depends on the specific requirements, financial considerations, and prevailing conditions at the wastewater treatment plant. It is imperative to choose a membrane that is compatible with the chemicals present in the wastewater and capable of withstanding the harsh conditions prevalent at the facility. In conclusion, a waterproofing membrane proves to be an appropriate solution for wastewater treatment plants as it effectively safeguards the structure against water infiltration and chemical harm. By implementing an appropriate waterproofing system, the facility can ensure the long-term durability and operational effectiveness of the plant.

- Q: Does a waterproofing membrane provide any insulation benefits?

- A waterproofing membrane does not offer any insulation benefits, unlike insulation which is specifically designed to regulate temperature and prevent heat transfer. The primary function of a waterproofing membrane is to safeguard the underlying structure from water damage by creating a barrier that prevents water from penetrating through the surface. This barrier acts as a protective shield, maintaining the structure's integrity and keeping water out. On the other hand, insulation materials are installed within the walls, floors, or roofs of a building to provide thermal resistance and enhance energy efficiency. Insulation works by reducing the transfer of heat between the interior and exterior of the building, thus creating a comfortable indoor environment. While both waterproofing and insulation contribute to the overall performance and durability of a building, they serve distinct purposes. Waterproofing focuses solely on keeping water out, whereas insulation focuses on temperature regulation. To achieve optimal results, it is crucial to utilize appropriate waterproofing and insulation materials in their respective areas.

- Q: Can a waterproofing membrane be used on concrete tanks?

- Yes, a waterproofing membrane can be used on concrete tanks. Waterproofing membranes are commonly used to prevent water leakage and provide protection against water ingress in various structures, including concrete tanks. These membranes create a barrier that prevents water from penetrating the concrete surface, ensuring the tank remains watertight and protected against moisture damage.

- Q: Can a waterproofing membrane be applied to tiled surfaces?

- Yes, a waterproofing membrane can be applied to tiled surfaces. In fact, it is common practice to use a waterproofing membrane underneath tiled surfaces, especially in areas prone to moisture such as bathrooms, showers, and kitchen backsplashes. The waterproofing membrane acts as a barrier to prevent water penetration into the substrate, protecting the tiles and the underlying structure from water damage. It is important to ensure that the tiled surface is properly prepared and free from any cracks or damage before applying the waterproofing membrane to achieve optimal results.

- Q: Can a waterproofing membrane be used as a vapor barrier?

- Yes, a waterproofing membrane can be used as a vapor barrier. Waterproofing membranes are designed to prevent the passage of water through a surface, such as a roof or foundation. In the process of preventing water penetration, these membranes also act as a vapor barrier, stopping the movement of water vapor. This helps to reduce the risk of condensation and moisture-related issues within a structure. However, it is important to note that not all waterproofing membranes are created equal and may have different levels of vapor resistance. Therefore, it is essential to select a waterproofing membrane that is specifically designed to also act as a vapor barrier if that is a requirement for the intended application.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer serves multiple purposes. Firstly, it helps to prevent damage to the waterproofing membrane during and after installation. It acts as a barrier against sharp objects, construction debris, and potential punctures. Additionally, the protective layer helps to distribute loads evenly and provide stability to the membrane, reducing the risk of damage caused by foot traffic or heavy equipment. Furthermore, the protective layer serves as a UV barrier, shielding the waterproofing membrane from the harmful effects of sunlight exposure. UV rays can degrade the membrane over time, leading to reduced effectiveness and potential leaks. The protective layer also helps to regulate temperature fluctuations, which can expand and contract the membrane, causing stress and compromising its waterproofing capabilities. In summary, a protective layer is essential for the longevity and performance of a waterproofing membrane. It safeguards against physical damage, UV radiation, and temperature fluctuations, ensuring the membrane's effectiveness in keeping water out and preserving the integrity of the structure it protects.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- Yes, a waterproofing membrane can be used in conjunction with expansion joint systems. The membrane can be applied over the expansion joint system to provide an additional layer of protection against water penetration, ensuring the longevity and effectiveness of the joint system.

Send your message to us

EPDM Rubber Waterproof Membrane for Roofing, Basement, Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3600 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords