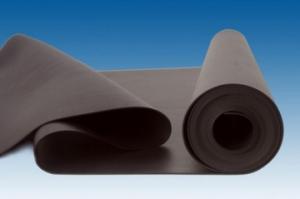

EPDM Waterproof Membrance for Roof and Basement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 15000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Waterproof Membrane | Place of Origin: | Shandong, China (Mainland) | Brand Name: | hongyuan |

Model Number: | Excaid-D | thickness:1.2mm,1.5mm,2.0mm: | Raw mateiral:EPDM rubber | width:1200mm: | Standard:GB18173.1--2006 |

length:20m: | Tear strength:>=25KN/m | break tensile strength >=7.5MPa: | waterproof:0.3MPa,30min | break elongation:>=450%: | usage:building waterproof |

Packaging & Delivery

Packaging Details: | PE membrane and pallet |

Delivery Detail: | within 20 days after receiving downpayment |

Usage range:

Bridge building, storage, road, tunnel, parking station, swimming pool, water-disposal pool, rubbish-disposal places and other waterproofing project, especially for,easy broken structural and cold building protective

Features:

a) Conforms to the national standards

b) SBS modified bitumen waterproof membrane is specially used as waterproof material in cold area

c) APP is specially suitable for areas of high temperature and of strong sun-shine

Technical Specification:

Type | Waterproof Membrane | |||

Material | EPDM RUBBER | |||

Thickness | 1.2mm; 1.5mm;2.0mm | |||

Weight(kg/m2) | 1.2mm | 1.5mm | 2.0mm | |

1.54-1.58 | 1.79-1.83 | 2.25-2.29 | ||

Length | 20m/Roll | |||

Width | 1.2m | |||

Usage | basements, ponds, Lake, steel structure roofing, underground, tunnels etc. | |||

Packing | 24 sqm/ROLL | |||

Loading in Container | ROLLS | |||

Colors | customized | |||

Enclosure | ||||

Technical Data:

Tensile Strength N/CM | Normal temperature: ≥60 ; 60°C: ≥30 |

Breaking Elongation % | Normal temperature:≥400 ; -20°C: ≥10 |

Tear Resistance N | ≥20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | ≥ -20 |

Heating Shrinking mm | Extension: ≥2 Shrink:≥4 |

Heat Resistance (80°C×168h) | Tensile Strength % : ≥80 ; Keeping rate of adhesive breaking:≥70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : ≥80 ; Keeping rate of adhesive breaking:≥80 |

Synthetic aging | Tensile Strength % : ≥80 ; Keeping rate of adhesive breaking:≥80

|

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Indeed, temporary structures or tents can benefit from the utilization of a waterproofing membrane. These membranes are specifically crafted to create a safeguarding shield against water, thwarting any potential harm caused by water infiltration. Consequently, they prove to be an excellent selection for temporary structures or tents, ensuring that the interior remains dry in inclement weather or damp environments. Furthermore, the lightweight and pliable nature of waterproofing membranes simplifies their installation and removal, which is particularly advantageous for temporary structures or tents that necessitate relocation or disassembly.

- Q: Can waterproofing membranes be used on utility vaults?

- Utility vaults, which are commonly found underground and contain vital utility equipment like electrical transformers, water meters, and communication systems, can benefit from the use of waterproofing membranes. These structures are vulnerable to water infiltration, which can harm the equipment and disrupt its operation. To prevent water from entering utility vaults, waterproofing membranes are often employed. These membranes, typically composed of robust materials like rubber, PVC, or modified bitumen, form an impenetrable barrier against moisture. Applied to the walls and floors of the vault, they establish a tight seal that wards off any water seepage. By employing waterproofing membranes on utility vaults, the risk of water damage is significantly diminished. This safeguard ensures that the equipment housed within remains functional and undamaged for an extended period. Additionally, these membranes offer protection against other potential issues, such as leaks, corrosion, and chemical damage. However, it is crucial to note that the proper preparation of the surface and correct installation techniques are essential for a successful and enduring waterproofing system on utility vaults. Therefore, it is advisable to consult a professional waterproofing contractor with experience in working on utility vaults to achieve optimal results.

- Q: Do you know how many square meters of waterproofing membrane to send a set of tests?

- Elastomer Asphalt Waterproofing Sheets: Take a roll out of the outer roll head 2500mm, the vertical cut 800mm full-width coil sample 2. 10000 square meters for a group, the lack of a group also.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They can effectively prevent water intrusion and protect homes from moisture damage, making them an ideal solution for basements, foundations, roofs, and other areas prone to water leakage.

- Q: Can a waterproofing membrane be used on balconies and decks?

- Balconies and decks can benefit greatly from the use of a waterproofing membrane. It is highly recommended to install this protective layer to safeguard against water damage. These outdoor areas are exposed to rain, snow, and other weather conditions, which can lead to issues like rot, mold, and structural deterioration if water seeps into the structure. By applying a waterproofing membrane beneath the surface material, such as tiles or decking, a barrier is created that prevents water from penetrating and redirects it away from the structure. This not only prolongs the life of the balcony or deck but also preserves its visual appeal. Moreover, the use of a waterproofing membrane is particularly crucial for balconies located above living spaces, as it prevents water from dripping down. In conclusion, incorporating a waterproofing membrane is an effective solution to ensure the durability and functionality of balconies and decks.

- Q: Can a waterproofing membrane be used on plastic block surfaces?

- Yes, a waterproofing membrane can be used on plastic block surfaces. These membranes are designed to provide a protective barrier against moisture, preventing water from seeping through the surface. Plastic blocks, like any other surface, can be susceptible to water damage if not properly protected. Applying a waterproofing membrane can help seal and protect the plastic blocks, preventing water penetration and potential damage. It is important to choose a waterproofing membrane that is compatible with plastic materials and follow the manufacturer's instructions for application to ensure the best results.

- Q: Are waterproofing membranes suitable for crawl spaces?

- Yes, waterproofing membranes are suitable for crawl spaces as they provide a protective barrier against moisture and water intrusion, preventing issues such as mold growth, structural damage, and musty odors.

- Q: Can a waterproofing membrane be used in conjunction with other waterproofing methods?

- Yes, a waterproofing membrane can be used in conjunction with other waterproofing methods. In fact, it is quite common to combine multiple waterproofing techniques to provide enhanced protection against water intrusion. Waterproofing membranes are often used as a primary waterproofing layer, providing a barrier against water penetration. However, they can be further reinforced by using other methods such as sealants, coatings, or drainage systems. These additional methods can help to address specific vulnerabilities, such as cracks, joints, or areas prone to high water pressure. By combining different waterproofing techniques, it is possible to create a comprehensive and effective waterproofing system that offers maximum protection against water damage.

- Q: What are the different thickness options for a waterproofing membrane?

- Waterproofing membranes are available in a range of thicknesses to accommodate different needs and uses. Typically, the thickness of a waterproofing membrane can vary from 0.5 mm to 2.0 mm. For applications that require a flexible and lightweight solution, thinner waterproofing membranes, measuring between 0.5 mm and 0.8 mm, are often utilized. These membranes are commonly employed in residential waterproofing projects, such as roof decks, balconies, and basements. Additionally, they are suitable for areas with minimal foot traffic or limited space, as their thin profile allows for easy installation and minimal disruption to the existing structure. In both residential and commercial applications, medium-thickness waterproofing membranes, ranging from 1.0 mm to 1.5 mm, are frequently used. These membranes offer a balance between flexibility and durability, making them appropriate for areas that may experience moderate to heavy foot traffic or require additional protection. Common areas of application include shower enclosures, wet rooms, and exterior walls. Thicker waterproofing membranes, typically measuring 1.5 mm to 2.0 mm, are often preferred for high-demand applications or areas exposed to extreme conditions. These membranes provide enhanced strength, resilience, and resistance to punctures and abrasions. They are commonly utilized in industrial settings, commercial buildings, and civil engineering projects, such as tunnels, bridges, and parking structures. It is important to note that the appropriate thickness option for a waterproofing membrane depends on specific project requirements, including anticipated usage, exposure to moisture, and expected loads. Therefore, it is advisable to consult with a professional or manufacturer to determine the most suitable thickness option for a particular application.

- Q: Can a waterproofing membrane be used in cold climates?

- Indeed, a waterproofing membrane is suitable for use in cold climates. It is highly advisable to utilize a waterproofing membrane in cold climates to safeguard structures from moisture damage caused by snow, ice, and freezing temperatures. These membranes are engineered to possess flexibility and durability, enabling them to endure extreme temperature fluctuations without experiencing cracks or deterioration. They establish a barrier that thwarts water from permeating the structure, a critical factor in cold climates where water can freeze and expand, resulting in substantial harm to buildings and infrastructure. Additionally, certain waterproofing membranes are specifically formulated to excel in cold weather conditions, offering heightened resistance to freeze-thaw cycles and ensuring long-term protection against water infiltration. Therefore, it is imperative to employ a high-quality waterproofing membrane in cold climates to uphold the integrity and longevity of structures.

Send your message to us

EPDM Waterproof Membrance for Roof and Basement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 15000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords