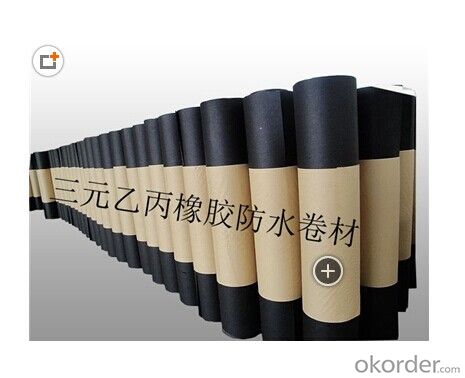

EPDM Rubber Roofing Waterproof Membrane 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM Waterproof Membrane (Ethylene Propylene Diene Monomer) is a synthetic rubber, highly flexible stable material that is not only easy to work with, but long lasting and aquatic safe.

Property for EPDM Waterproof Membrane

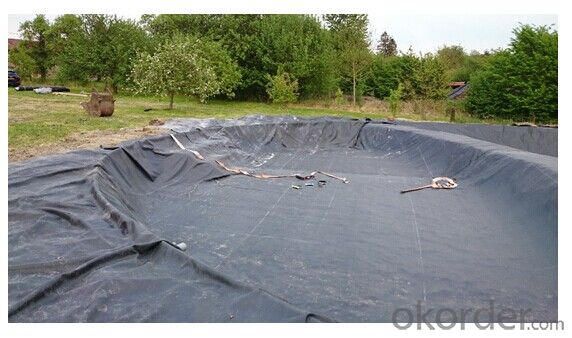

1)AQUATIC SAFE

A highly stable material that is formulated for safety when exposed to fish and plant life in a decorative pond

2)HIGHLY FLEXIBLE

Stays flexible in temperatures from -40° Fahrenheit to 175° Fahrenheit making it easy to install year round. Unlike other liner materials, it does not contain plasticizers that could make it become brittle with age and cause cracks or splits in the material, threatening aquatic life.

3)DESIGN VERSATILITY

EPDM's flexibility provides more versatility in the pond design. Unlike preformed liners, it can be easily shaped to fit the unique contours of the pond dimensions, allowing a more creative design

4)WEATHER RESISTANT

Remarkable resistance to the harmful effects of ultraviolet radiation (UV), ozone and other environmental conditions.

5)HIGH ELONGATION

High expansion and contraction characteristics that enable it to conform to objects in the sub grade. Should earth movement occur, rocks and tree roots could be dislodged beneath the liner, but EPDM's high elongation will enable it to stretch over such objects.

6)MINIMAL MAINTENANCE

Requires little or no regular maintenance once installed. However, if repair becomes necessary, it is easy to do without removing the liner from the pond with the EPDM repair patch.

Uses for EPDM Waterproof Membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Data for EPDM Waterproof Membrane

Item | value | ||

JL1 | JF1 | ||

Tensile Strength (Mpa) | normal tamperature | 7.5 | 4.0 |

60°C ≥ | 2.3 | 0.8 | |

Elongation at break (%) | normal tamperature ≥ | 450 | 450 |

-20°C ≥ | 200 | 200 | |

Tear Resistance (N) | ≥ | 25 | 18 |

Water impermeability | 30mm | 0.3Mpa | 0.3Mpa |

Cold bending | (°C) ≤ | -40 | -30 |

Heating Shrinking rate | extand << span=""> | 2 | 2 |

shrink << span=""> | 4 | 4 | |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can waterproofing membranes be used on concrete tunnels?

- Yes, waterproofing membranes can be used on concrete tunnels. Waterproofing membranes are commonly used to provide a barrier against water infiltration in various structures, including concrete tunnels. These membranes, which can be made of various materials such as bitumen, PVC, or EPDM, are applied on the exterior surface of the tunnel walls to prevent water from seeping through the concrete. By creating a waterproof layer, these membranes help protect the tunnel from water damage, such as corrosion, deterioration, and leaks. Additionally, waterproofing membranes also provide a protective barrier against other potential sources of moisture, such as groundwater or surface water. It is important to ensure that the selected waterproofing membrane is suitable for the specific conditions and requirements of the concrete tunnel, taking into account factors such as the level of water pressure, chemical exposure, and temperature variations. Proper installation and regular maintenance of the waterproofing membrane are crucial to ensure its effectiveness and long-term durability in protecting the concrete tunnel from water ingress.

- Q: Does a waterproofing membrane require any special cleaning or maintenance procedures?

- Yes, a waterproofing membrane typically requires special cleaning and maintenance procedures to ensure its effectiveness and longevity. Regular inspections, cleaning off debris, and addressing any damage or wear are essential to prevent leaks or deterioration. Additionally, specific cleaning products and techniques may be recommended by the manufacturer or installer to maintain the membrane's performance.

- Q: Are waterproofing membranes resistant to earthquake-induced water pressure?

- Waterproofing membranes can provide some level of resistance to earthquake-induced water pressure, but their effectiveness may vary depending on the specific membrane and the magnitude of the earthquake. Waterproofing membranes are designed to create a barrier against water infiltration, protecting the structure from water damage. However, they are not specifically designed to withstand the pressure caused by earthquakes. During an earthquake, the ground can experience significant shaking and movement, which can result in increased water pressure in the surrounding soil and groundwater. This increased pressure can potentially cause water to seep through the waterproofing membrane, compromising its effectiveness. To enhance the resistance of waterproofing membranes to earthquake-induced water pressure, additional measures may be required. These can include reinforcing the membrane with materials that can absorb shock and movement, installing drainage systems to alleviate excessive water pressure, and ensuring proper installation and maintenance of the membrane. It is important to consult with a professional waterproofing expert or structural engineer to determine the most suitable waterproofing system for earthquake-prone areas. They can provide guidance on selecting membranes that are specifically designed to withstand higher water pressure and offer better protection against earthquakes.

- Q: What are the common mistakes to avoid when installing a waterproofing membrane?

- When installing a waterproofing membrane, it is important to avoid certain common mistakes to ensure its effectiveness and longevity. Some of the common mistakes to avoid include: 1. Inadequate surface preparation: One of the most common mistakes is not properly preparing the surface before installing the membrane. This can include not cleaning the surface thoroughly, not filling cracks or holes, or not removing loose debris. Inadequate surface preparation can compromise the adhesion of the membrane and lead to leaks. 2. Improper membrane selection: Choosing the wrong type of waterproofing membrane can be a costly mistake. Different membranes are designed for specific applications and environmental conditions. It is crucial to select a membrane that is suitable for the specific project requirements to ensure its effectiveness and durability. 3. Inadequate membrane overlap: Properly overlapping the membrane is essential to create a continuous barrier against water infiltration. Inadequate overlap can lead to water seepage and compromise the integrity of the waterproofing system. It is important to follow the manufacturer's instructions regarding the recommended overlap width and ensure proper adhesion between the overlapped sections. 4. Incorrect membrane installation: Improper installation techniques can also lead to issues with the waterproofing membrane. This can include not applying the membrane evenly or not using the correct tools for installation. It is crucial to follow the manufacturer's guidelines and recommendations for installation to ensure a proper and effective waterproofing system. 5. Neglecting proper drainage: Waterproofing membranes should always be accompanied by an adequate drainage system. Failing to install proper drainage can result in water pooling on the surface, which can lead to membrane degradation and potential leaks. It is important to consider the slope and design of the drainage system to ensure efficient water removal. 6. Lack of regular inspection and maintenance: Once the waterproofing membrane is installed, it is important to regularly inspect and maintain it. Neglecting regular inspections and maintenance can lead to issues going unnoticed, such as damage or deterioration, which can compromise the waterproofing system. Regular inspections and timely repairs or maintenance can help prolong the life of the membrane and avoid costly repairs in the future. By avoiding these common mistakes during the installation process and ensuring proper maintenance, you can enhance the effectiveness and longevity of your waterproofing membrane, providing reliable protection against water infiltration.

- Q: Can a waterproofing membrane be applied on a vertical surface?

- Yes, a waterproofing membrane can be applied on a vertical surface. In fact, waterproofing membranes are commonly used on vertical surfaces such as walls, foundations, and retaining walls to prevent water infiltration and protect the underlying structures. These membranes are designed to adhere to vertical surfaces and create a barrier that prevents water from penetrating through. They are typically applied using a variety of techniques including spray or roller application, and can be used in both new construction and renovation projects. The use of a waterproofing membrane on a vertical surface is an effective way to ensure the long-term durability and integrity of the structure by preventing water damage.

- Q: Can a waterproofing membrane be used on concrete block walls?

- Concrete block walls are prone to water infiltration, which can cause problems like mold, mildew, and structural harm. To combat this, a waterproofing membrane can be utilized on the walls. This membrane acts as a protective shield, applied to the surface of the concrete blocks, effectively stopping water from seeping in. By creating a moisture-resistant barrier, it establishes a tight seal, preventing water from entering the interior of the walls. This aids in preserving the walls' integrity and safeguards against water-related damage. However, it is crucial to ensure that the waterproofing membrane is correctly installed and that any existing cracks or gaps in the concrete block walls are adequately sealed before its application.

- Q: Can a waterproofing membrane be used for storage tanks or containment areas?

- Storage tanks or containment areas can utilize a waterproofing membrane to prevent water or liquid penetration. These membranes serve as a barrier against such infiltrations and are therefore ideal for containment purposes. Rubber, PVC, or bitumen are commonly used materials for these membranes due to their water-resistant properties. They can be applied either internally or externally to storage tanks or containment areas to safeguard against leaks and moisture-related deterioration. Moreover, the use of waterproofing membranes aids in preventing the development of mold or mildew, thereby ensuring a secure and hygienic environment for stored materials or liquids.

- Q: Can a waterproofing membrane be used as a vapor barrier?

- Indeed, a vapor barrier can be achieved by utilizing a waterproofing membrane. The main purpose of waterproofing membranes is to obstruct the flow of water across various surfaces, such as roofs or foundations. As a result of their water-repelling capabilities, these membranes simultaneously serve as vapor barriers, hindering the movement of water vapor. This serves to minimize the likelihood of condensation and other moisture-related problems within a structure. Nonetheless, it is crucial to acknowledge that not all waterproofing membranes possess the same degree of vapor resistance. Consequently, it is imperative to carefully select a waterproofing membrane that is explicitly designed to function as a vapor barrier, should this be a necessity for the intended application.

- Q: Are waterproofing membranes resistant to acid exposure?

- The resistance of waterproofing membranes to acid exposure can differ depending on the specific type of membrane used. Certain waterproofing membranes are engineered to withstand acid exposure, whereas others may not have the same resistance. Therefore, it is of utmost importance to meticulously choose the suitable waterproofing membrane for the particular application and environment where acid exposure could be an issue. Seeking guidance from manufacturers or industry professionals is also recommended in order to determine the most effective waterproofing membrane solution for areas prone to acid.

- Q: Can a waterproofing membrane be used on roofs?

- Yes, a waterproofing membrane can be used on roofs. Waterproofing membranes are commonly used on flat or low-slope roofs to provide an additional layer of protection against water infiltration. These membranes are typically made from synthetic materials such as modified bitumen, EPDM (ethylene propylene diene monomer), PVC (polyvinyl chloride), or TPO (thermoplastic olefin). They are designed to be durable, flexible, and resistant to UV rays, weathering, and ponding water. When properly installed, a waterproofing membrane can effectively prevent water from seeping into the underlying roof structure, protecting the building from leaks and water damage.

Send your message to us

EPDM Rubber Roofing Waterproof Membrane 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords