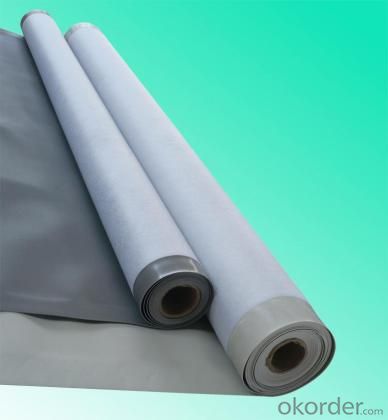

EPDM Rubber Sheet for Waterproofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

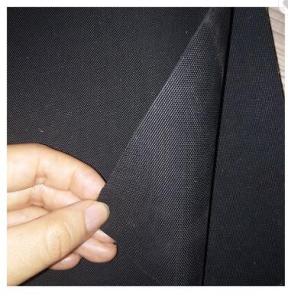

Introduciton of EPDM Rubber Sheet for Waterproofing Industry:

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylenepropylene rubber of KINTOPbrand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Features of EPDM Rubber Sheet for Waterproofing Industry:

Excellent weatherability, durability and size stability.

Good adaptability to high and low temperature, UV resistant and anti-corrosion.

High tensile strength and good elongation, accommodating substrate movement.

Easy installation, environment friendly.

Good rooting penetration resistance.

Service life up to 50 years.

Applications of EPDM Rubber Sheet for Waterproofing Industry:

Subways, tunnels, roofs, basement.

Industrial and civil building waterproofing, like water reservior, bridge, dam, etc.

Geosynthetic liner for swimming pool, channels, irrigation system

Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

Technical Data of EPDM Rubber Sheet for Waterproofing Industry:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

- Q: Can a waterproofing membrane be used for a basement floor moisture barrier?

- Indeed, a basement floor moisture barrier can be established by utilizing a waterproofing membrane. The primary purpose of a waterproofing membrane is to impede the penetration of water into surfaces, thereby offering a highly efficient solution for safeguarding a basement floor against moisture. Through the application of a waterproofing membrane, a protective barrier is formed to prevent water from infiltrating the concrete floor, subsequently minimizing the potential hazards of mold, mildew, and water damage. To attain optimal effectiveness, it is crucial to ensure the accurate installation of the waterproofing membrane, covering the entirety of the basement floor. Moreover, it is advisable to seek guidance from a professional to ascertain the most appropriate type of waterproofing membrane suitable for your specific basement floor and moisture conditions.

- Q: Is a waterproofing membrane resistant to gasoline or other petroleum-based substances?

- Yes, a waterproofing membrane is generally resistant to gasoline and other petroleum-based substances.

- Q: Are waterproofing membranes resistant to thermal cycling?

- Yes, waterproofing membranes are generally resistant to thermal cycling. These membranes are designed to withstand changes in temperature without losing their effectiveness. Thermal cycling refers to the repeated expansion and contraction of materials due to temperature fluctuations. Waterproofing membranes are engineered to have excellent dimensional stability, which means they can expand and contract with minimal deformation. This resistance to thermal cycling ensures that the membranes maintain their integrity and prevent water penetration, even in extreme temperature conditions. However, it is important to note that the specific resistance to thermal cycling can vary depending on the type and quality of the waterproofing membrane used.

- Q: How does a waterproofing membrane handle exposure to UV radiation?

- Waterproofing membranes are specifically designed to withstand exposure to UV radiation, which is a common environmental factor that can cause deterioration and degradation of materials over time. In order to counteract the damaging effects of UV radiation, manufacturers typically incorporate UV stabilizers and additives into the production of waterproofing membranes. These substances serve as a barrier, either absorbing or reflecting the UV rays and preventing them from penetrating the membrane. Additionally, certain waterproofing membranes may include extra protective layers or coatings that further enhance their resistance to UV radiation. Ultimately, the inclusion of UV stabilizers and protective layers in waterproofing membranes guarantees their ability to endure prolonged exposure to UV radiation without compromising their performance or integrity.

- Q: Can a waterproofing membrane be used for a stadium seating area?

- Yes, a waterproofing membrane can be used for a stadium seating area. A waterproofing membrane is a material that is designed to prevent the penetration of water into a structure. It is commonly used in building construction to protect the foundation, roof, or walls from water damage. In the case of a stadium seating area, a waterproofing membrane can be applied to the concrete or other flooring material to prevent water from seeping through and causing damage. This is especially important in outdoor stadiums where rain or other forms of moisture can accumulate and potentially lead to long-term structural issues. By using a waterproofing membrane, the seating area can be protected from water damage, ensuring its longevity and safety for spectators.

- Q: Can a waterproofing membrane be used for a green roof system?

- Yes, a waterproofing membrane can be used for a green roof system. In fact, a high-quality waterproofing membrane is an essential component of a green roof system. Green roofs are designed to support the growth of vegetation and require a durable and reliable waterproofing barrier to prevent water leakage and protect the underlying structure from moisture damage. A waterproofing membrane acts as a protective layer, effectively sealing the roof and preventing water from penetrating into the building. Additionally, the membrane helps to retain water within the green roof system, ensuring that the plants receive an adequate water supply. Therefore, integrating a waterproofing membrane into a green roof system is crucial for its success and longevity.

- Q: Are waterproofing membranes easy to install?

- Waterproofing membranes are generally easy to put in place. They can be found in various forms, such as sheets, rolls, or liquid coatings, which allows them to adapt to different surfaces and uses. Typically, the process involves cleaning and preparing the surface, applying the membrane, and ensuring a proper seal. While some technical knowledge and tools may be necessary, manufacturers often provide detailed instructions and guidelines for installation, making it easier for professionals and DIY enthusiasts alike. Furthermore, advancements in technology have resulted in the creation of self-adhesive membranes, which make the installation process even simpler. All in all, with proper preparation and following the correct installation procedures, waterproofing membranes can be installed relatively effortlessly.

- Q: Can waterproofing membranes be applied in cold weather?

- Indeed, waterproofing membranes are capable of being applied in chilly conditions. Nevertheless, it is imperative to take into account several factors when carrying out the application of these membranes in low temperatures. The curing process of the membrane can be affected by cold weather, which has the potential to decelerate it. Consequently, it is of utmost importance to ensure that the surface to be waterproofed is devoid of moisture, ice, or frost prior to the application of the membrane. Furthermore, certain waterproofing products might possess specific temperature prerequisites for attaining optimal performance, thus referring to the manufacturer's guidelines becomes indispensable. In colder temperatures, the employment of specialized adhesives or primers tailored for cold weather applications may also become necessary. All in all, by adopting appropriate precautions and utilizing suitable materials, it is feasible to successfully apply waterproofing membranes in cold weather.

- Q: How does a waterproofing membrane handle exposure to chemicals or solvents?

- A waterproofing membrane is designed to be resistant to chemicals and solvents, allowing it to handle exposure without being damaged or deteriorated.

- Q: Can a waterproofing membrane be used in hospitals or healthcare facilities?

- Yes, a waterproofing membrane can be used in hospitals or healthcare facilities. It is often used in areas that require protection against moisture, such as bathrooms, operating rooms, and laboratories, to prevent water damage and maintain a hygienic environment.

Send your message to us

EPDM Rubber Sheet for Waterproofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords