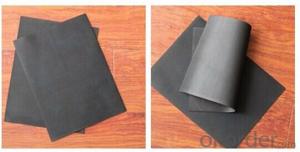

EPDM Waterproof Rubber Sheet for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Waterproof Rubber Sheet for Roofing Industry:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

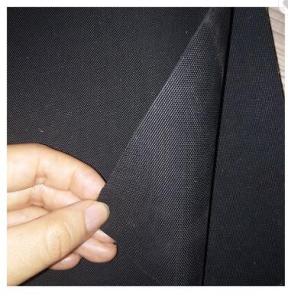

Main Features of Waterproof Rubber Sheet for Roofing Industry:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Application of EPDM Waterproof Rubber Sheet for Roofing Industry:

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Technical Parameters of EPDM Waterproof Rubber Sheet for Roofing Industry:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. What is your main market?

Our EPDM Waterproof Membrane for Roofing Industry sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

3. What is your advantage for EPDM Waterproof Membrane for Roofing Industry ?

With the most advanced production line, our good quality is based on superior material imported from America.

- Q: Can a waterproofing membrane be installed over existing coatings or sealants?

- Yes, a waterproofing membrane can be installed over existing coatings or sealants, depending on the condition of the existing surface. However, it is important to ensure that the surface is clean, dry, and free from any loose or damaged material before installing the membrane. Proper surface preparation is crucial to ensure the new membrane adheres well and provides effective waterproofing. It is also recommended to consult with a professional to determine the compatibility of the existing coatings or sealants with the waterproofing membrane to avoid any potential issues or failure of the system.

- Q: Are waterproofing membranes suitable for rooftop gardens?

- Yes, waterproofing membranes are suitable for rooftop gardens. They provide an effective barrier against water leakage and prevent any potential damage to the structure below. Additionally, these membranes also protect the plants and vegetation in the rooftop garden from excessive moisture, ensuring their healthy growth.

- Q: Can a waterproofing membrane be used for zoos or aquariums?

- Yes, a waterproofing membrane can be used for zoos or aquariums. Waterproofing membranes are designed to prevent water penetration and provide a watertight barrier, making them suitable for use in areas that require high levels of water resistance such as zoos or aquariums where water containment is critical.

- Q: Can waterproofing membranes be used on underground structures?

- Yes, waterproofing membranes can be used on underground structures.

- Q: Does a waterproofing membrane prevent water infiltration through concrete or other building materials?

- Yes, a waterproofing membrane is designed to prevent water infiltration through concrete or other building materials. It acts as a barrier, effectively sealing off the surface and protecting the underlying structure from water damage.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Yes, a waterproofing membrane can be used in elevator pits or sump pits to prevent water infiltration and protect the structure from potential damage caused by moisture.

- Q: Can a waterproofing membrane be installed by a homeowner or is professional installation required?

- Although a homeowner can technically install a waterproofing membrane, it is strongly advised to enlist the services of a professional. Several factors must be taken into consideration, making professional installation the superior choice. To begin with, proper installation of waterproofing membranes necessitates specific knowledge and expertise. Professionals are trained in the correct techniques and possess experience working with various membrane types. They understand the intricacies of the process, including surface preparation, membrane application, and sealing. This expertise guarantees correct installation and effective waterproofing. Furthermore, professionals have access to top-quality materials and tools that homeowners may not readily have access to. They possess knowledge of which membrane type is appropriate for various applications and can recommend the best product based on individual needs. Additionally, professionals have access to specialized equipment, enabling more efficient and effective installation. In addition, professional installation offers the advantage of warranties and guarantees. Reputable waterproofing companies typically provide warranties for their services, providing homeowners with peace of mind. They can trust that any issues that arise will be addressed and resolved by the professionals. Lastly, waterproofing is essential for safeguarding homes against water damage and maintaining structural integrity. Improper installation or a faulty membrane can lead to water leaks, mold growth, and expensive repairs. By hiring a professional, homeowners can be confident that the waterproofing membrane will be installed correctly, reducing the risk of future problems. In conclusion, while it is possible for homeowners to install waterproofing membranes themselves, the complexities of the process and the advantages of professional installation make it highly recommended to hire a professional for this task. Their expertise, access to quality materials, warranties, and guarantees provide homeowners with the reassurance that the job will be carried out correctly and effectively, ultimately protecting their homes from water damage.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Using a waterproofing membrane in crawlspaces or basements is highly recommended. These areas are prone to water seepage and high humidity levels, which can cause mold growth, structural issues, and damage to stored items. By effectively sealing the foundation walls and floor, a waterproofing membrane acts as a barrier against water intrusion. It creates a watertight seal that keeps the space dry and protected. Furthermore, waterproofing membranes help control moisture levels by reducing condensation and humidity, creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is crucial for ensuring the structure's longevity and integrity and protecting against potential water-related problems.

- Q: Are waterproofing membranes resistant to acid exposure?

- Yes, waterproofing membranes are generally resistant to acid exposure. They are designed to provide a barrier against water and other corrosive substances, including acids. However, the level of resistance may vary depending on the specific type and quality of the membrane used.

- Q: What is the resistance type SBS waterproofing membrane?

- The second is chemical resistance, in the waterproofing membrane production process, adding chemical resistance agent, similar to the chemical composition of herbicides, the plant roots are not close to the waterproofing membrane; In addition, copper ions have a similar effect.

Send your message to us

EPDM Waterproof Rubber Sheet for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords