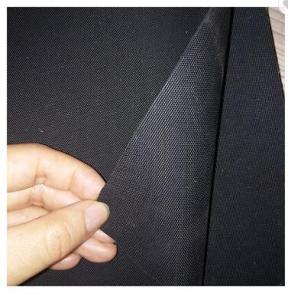

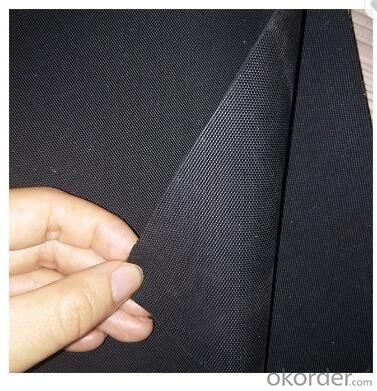

Roofing Waterproof Membrane/EPDM Rubber Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane Specifications:

EPDM rubber waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing projects applications, which has high flexibility and bendable property for all kinds of buildings.

Type | EPDM Rubber Waterproof Membrane | ||

Type | Vulcanized and Weldable | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m (width) * 20m (length)/roll. Weldable type could be 4m wide. | ||

Packing | 24㎡/roll, with plastic bag. (Weldable: 80㎡/roll) | ||

Usage | Roof, basement, pond, Lake, steel structure roofing, underground, tunnel, etc | ||

EPDM Waterproof Membrane Property:

•Excellent anti-ageing,prolonged longevity;long service life.

•Good strength and tensity/Suitable for a wide range of temperatures

•Great high-temperature,low-temperature resistance

•Single layer applied is applicable and cold applied

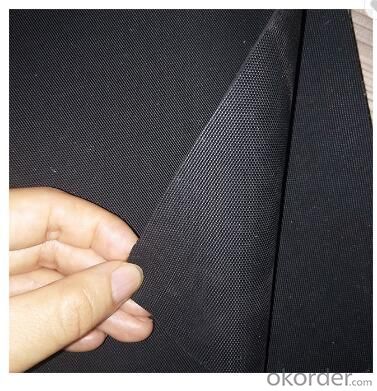

EPDM Waterproof Membrane Application:

Applicable to all kinds of roofing, basement, tunnel light building waterproofing engineering;

roofing and underground engineering, storage tanks, municipal, bridges, subways, tunnels, dams, etc.

- Q: What are the different sizes of earthwork products available?

- The sizes of earthwork products can vary depending on the specific project and requirements. Generally, earthwork products such as gravel, sand, and soil are available in different sizes ranging from fine to coarse. Gravel can come in sizes like 3/8 inch, ¾ inch, or 1 inch, while sand may be available in fine, medium, or coarse grades. Soil is typically classified into different types based on particle size, such as clay, silt, or sand. Ultimately, the size of earthwork products needed will depend on the intended use and specifications of the project.

- Q: What is the function of geosynthetic drainage materials in road shoulder construction?

- Geosynthetic drainage materials in road shoulder construction serve the function of enhancing drainage efficiency by providing a pathway for water to flow away from the road surface. They help prevent the accumulation of water in the road shoulder, which can lead to softening of the soil and potential damage to the road structure.

- Q: Can earthwork products be used in bridge abutment construction?

- Yes, earthwork products can be used in bridge abutment construction. Earthwork products such as fill materials, geotextiles, and retaining walls are commonly used to support and stabilize bridge abutments. These products help in providing a solid foundation, preventing erosion, and ensuring the stability and longevity of the abutment structure.

- Q: How are geotextile tubes used in sediment control during dredging operations?

- Geotextile tubes are used in sediment control during dredging operations as they provide an effective and environmentally friendly solution for containing and dewatering sediment. These tubes are filled with the dredged material and the water is allowed to drain out, leaving behind the captured sediment. The geotextile fabric acts as a filter, allowing water to pass through while retaining the sediment. This method helps prevent sediment from spreading and contaminating nearby water bodies, ensuring compliance with environmental regulations.

- Q: Can corrugated metal pipes be used as culverts?

- Yes, corrugated metal pipes can be used as culverts. They are commonly used in various applications, including culverts, due to their durability, strength, and cost-effectiveness. Corrugated metal pipes are designed to efficiently convey water and other fluids, making them suitable for facilitating the flow of water under roads, railways, or other structures.

- Q: What are the different cost considerations for earthwork products?

- The different cost considerations for earthwork products include the type and quality of materials used, the complexity and scale of the project, the labor and equipment required, site conditions and accessibility, transportation and logistics, permits and regulatory requirements, and any additional services or features requested.

- Q: Are earthwork products easy to install?

- Yes, earthwork products are generally easy to install. They are designed to be user-friendly and can be installed with basic tools and minimal expertise. The straightforward installation process ensures that homeowners or contractors can complete the installation efficiently and effectively.

- Q: What are the different types of geosynthetic tubes used in riverbank protection?

- There are several types of geosynthetic tubes used in riverbank protection, including geotextile tubes, geogrid tubes, and geocell tubes. Geotextile tubes are made of high-strength woven or non-woven geotextile fabric and filled with soil or other materials to form a stable barrier against erosion. Geogrid tubes, on the other hand, consist of geogrid panels connected together and filled with soil, providing reinforcement to the riverbank. Geocell tubes are three-dimensional honeycomb-like structures made of high-density polyethylene and filled with soil or aggregate, offering both erosion control and slope stabilization.

- Q: Can earthwork products be used for creating raised seating areas in stadiums?

- Yes, earthwork products can be used for creating raised seating areas in stadiums. Earthwork products like compacted soil, gravel, and retaining walls can be used to build elevated platforms or terraces, providing a solid foundation for the seating structure. These products can help create a stable and leveled surface, ensuring the safety and comfort of spectators in stadiums.

- Q: Are earthwork products suitable for use in swimming pool construction?

- Yes, earthwork products can be suitable for use in swimming pool construction. Earthwork products, such as compacted fill materials and engineered soil, can be used to create a stable foundation for the pool. Additionally, these products can be used to shape the terrain around the pool to ensure proper drainage and prevent water accumulation. However, it is important to consult with a professional pool builder or engineer to determine the specific earthwork products and techniques needed for the construction, considering factors such as soil composition, water table, and local building codes.

Send your message to us

Roofing Waterproof Membrane/EPDM Rubber Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords