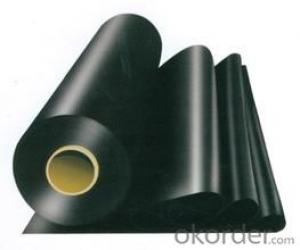

EPDM Rubber Waterproof Sheet for Single Layer Roof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3300 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane for Single Layer Roof System

Instruction for EPDM Single Layer Roof System:

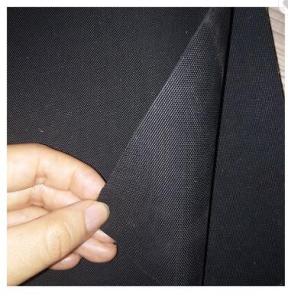

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Features of EPDM Single Layer Roof System:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications of EPDM Single Layer Roof System:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications of EPDM Single Layer Roof System:

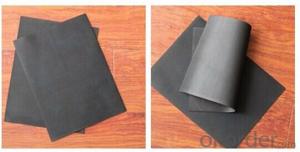

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

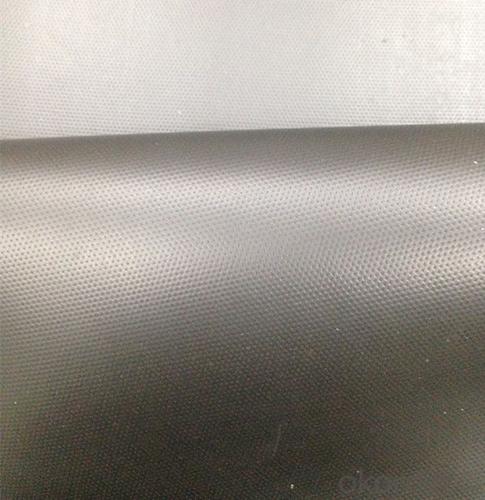

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos of EPDM Single Layer Roof System:

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Certainly! When installing tile or stone, it is highly recommended to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water from seeping into the underlying layers and causing damage. It is especially beneficial in wet areas, such as bathrooms, showers, and kitchen backsplashes. There are different types of waterproofing membranes available, such as liquid-applied, sheet, and fabric membranes. These can be applied to the substrate before installing the tile or stone, creating a waterproof layer that keeps the area dry and free from water-related issues. In addition to safeguarding against water damage, a waterproofing membrane also helps to prevent the growth of mold and mildew, which can be detrimental to both the installation and the health of those using the space. It is essential to note that proper installation of the waterproofing membrane is crucial for its effectiveness. Following the guidelines and best practices provided by the manufacturer ensures a tight seal and complete coverage. Overall, integrating a waterproofing membrane with tile or stone installations is a prudent decision. It enhances the project's durability and longevity while providing peace of mind against potential water damage.

- Q: Are waterproofing membranes resistant to mold and mildew?

- Yes, waterproofing membranes are resistant to mold and mildew. They create a barrier that prevents moisture from seeping through, which helps inhibit the growth of mold and mildew.

- Q: Can a waterproofing membrane be used for underground communication vaults?

- Yes, a waterproofing membrane can be used for underground communication vaults. Waterproofing membranes are commonly used in construction to prevent water infiltration and provide protection against moisture. In the case of underground communication vaults, where moisture and potential water leakage can be a concern, a waterproofing membrane can help ensure the integrity and longevity of the structure by creating a barrier against water intrusion.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Indeed, adobe block surfaces can be treated with a waterproofing membrane. These blocks, composed of a blend of clay, sand, and straw, are prone to water damage. By applying a waterproofing membrane, the infiltration of water can be prevented, thus safeguarding the adobe blocks against various moisture-related problems like cracking, erosion, or mold formation. It is essential to verify that the waterproofing membrane is suitable for adobe surfaces and adhere to the manufacturer's instructions for application. Furthermore, prior to applying the membrane, it is vital to adequately prepare the surface and address any preexisting damages to ensure optimal performance.

- Q: Can a waterproofing membrane be applied to concrete?

- Yes, a waterproofing membrane can be applied to concrete. In fact, it is a common and effective method used to protect concrete structures from water damage. The membrane is typically made of a flexible material, such as rubber or polymer, that is applied to the surface of the concrete. This creates a barrier that prevents water from penetrating the concrete and causing deterioration or structural damage. Waterproofing membranes can be applied to various types of concrete structures, including basements, foundations, roofs, and balconies. The application process typically involves cleaning and preparing the concrete surface, applying a primer if necessary, and then applying the membrane using a brush, roller, or spray. It is important to follow the manufacturer's instructions and ensure proper installation to achieve the desired level of waterproofing.

- Q: Are waterproofing membranes resistant to diesel fuel?

- Yes, waterproofing membranes are generally resistant to diesel fuel.

- Q: Can a waterproofing membrane be used in saunas?

- Indeed, a sauna can utilize a waterproofing membrane. Given that saunas consist of environments abundant in moisture, implementing a waterproofing membrane can effectively avert water damage and shield the underlying structure against moisture infiltration. The membrane functions as a barrier, effectively impeding the permeation of water and mitigating potential complications like mold growth, mildew formation, and rot. The selection of a waterproofing membrane specifically engineered for high-moisture regions, capable of withstanding the intense heat and humidity characteristic of saunas, is of utmost importance. Additionally, proper installation and adherence to manufacturer guidelines are essential to guarantee the efficiency and durability of the waterproofing membrane within a sauna setting.

- Q: Can a waterproofing membrane be used on both interior and exterior walls?

- Yes, a waterproofing membrane can be used on both interior and exterior walls. Waterproofing membranes are designed to prevent the penetration of water or moisture into the walls, regardless of whether they are located on the interior or exterior of a building. These membranes are typically made from materials such as rubber, modified bitumen, or liquid-applied coatings, and they provide an effective barrier against water infiltration. By applying a waterproofing membrane on both interior and exterior walls, you can ensure the long-term protection of your building from water damage, mold growth, and other moisture-related issues.

- Q: Can a waterproofing membrane be used for a stadium?

- Yes, a waterproofing membrane can be used for a stadium. A waterproofing membrane is designed to provide a barrier against water infiltration, making it an ideal solution for protecting the structure of a stadium from water damage. It can be used on various parts of the stadium, including the roof, walls, and foundation, to prevent leaks and moisture seepage. Additionally, a waterproofing membrane can help to extend the lifespan of the stadium by protecting it from the harmful effects of water, such as corrosion and mold growth. Overall, using a waterproofing membrane for a stadium is a practical and effective way to ensure its durability and longevity.

- Q: Can a waterproofing membrane be used for a stadium roof structure?

- Yes, a waterproofing membrane can be used for a stadium roof structure. A waterproofing membrane is a protective layer that prevents water from penetrating the roof and causing damage. It is typically made of materials such as rubber or synthetic polymers that are resistant to water. In the case of a stadium roof structure, a waterproofing membrane can be used to ensure that the roof remains watertight and prevents any leaks or water damage. This is particularly important for stadiums that have open-air or retractable roofs, as they are exposed to the elements and are more susceptible to water infiltration. A waterproofing membrane can be applied to various types of stadium roof structures, including metal, concrete, or even fabric roofs. It is typically installed beneath the roofing material, acting as a protective barrier against water. By preventing water from seeping into the roof, the membrane helps to extend the lifespan of the roof and protect the interior of the stadium from water damage. Additionally, a waterproofing membrane can also provide other benefits for a stadium roof structure. It can help to improve energy efficiency by reducing heat loss or gain through the roof. Some membranes also offer UV resistance, which helps to protect the roof from damaging ultraviolet rays. Overall, using a waterproofing membrane for a stadium roof structure is a practical and effective solution to ensure the roof remains watertight, durable, and protected from water damage.

Send your message to us

EPDM Rubber Waterproof Sheet for Single Layer Roof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3300 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords