EPDM Waterproofing Roofing Membrane with 1.2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

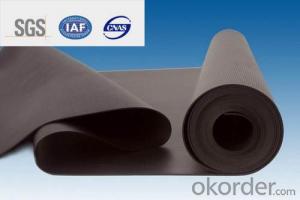

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How does a waterproofing membrane prevent water penetration?

- Waterproofing membranes act as a physical barrier, preventing water from entering the surface they are applied to. They are typically made of impermeable materials like synthetic polymers or bitumen. When properly applied, the membrane adheres tightly to the surface, forming a seamless layer that stops water seepage. Apart from water resistance, these membranes are designed to withstand various environmental conditions and resist damage caused by water pressure, temperature changes, and UV radiation. They are flexible and can accommodate structural movements without compromising their integrity. This flexibility ensures the membrane remains undamaged, preventing any gaps or cracks that water could exploit. Moreover, waterproofing membranes often incorporate additives or technologies that enhance their water resistance properties. These may include hydrophobic compounds that repel water or self-sealing capabilities, allowing the membrane to repair itself if punctured or damaged. In conclusion, a waterproofing membrane creates a durable, impermeable, and continuous barrier that resists water pressure, environmental factors, and structural movements. This barrier keeps the underlying surface dry and protected from potential water damage.

- Q: Are waterproofing membranes suitable for historical buildings?

- Yes, waterproofing membranes can be suitable for historical buildings. These membranes provide an effective solution for preventing water penetration and damage to the structure, helping to preserve the integrity and longevity of the building. However, it is essential to consider the specific requirements and characteristics of the historical building and select an appropriate membrane that is compatible with its materials and architectural features. Additionally, any waterproofing work should be done with sensitivity and care to ensure it does not compromise the historical value or aesthetics of the building.

- Q: Can a waterproofing membrane be used for oil or gas industry applications?

- The oil or gas industry can utilize a waterproofing membrane for various applications. These membranes are specifically designed to create a barrier against water penetration, making them highly advantageous in industries where oil or gas leaks and spills pose a significant concern. By preventing water from seeping into underground storage tanks or pipelines, these membranes safeguard against corrosion and potential environmental contamination. Moreover, they can be employed in areas where water might come into contact with oil or gas, such as containment areas or waste treatment facilities, ensuring that no substances escape into the surrounding environment. In summary, waterproofing membranes provide a dependable solution for safeguarding oil or gas industry infrastructure against water-related harm, thereby contributing to the integrity and safety of these operations.

- Q: Can a waterproofing membrane be used on precast zinc surfaces?

- Precast zinc surfaces can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to safeguard various surface types against water infiltration, including concrete, metal, and zinc. By creating a protective barrier, these membranes effectively prevent water from permeating the surface. This is especially crucial for precast zinc surfaces that are prone to exposure to moisture or water. The application of a waterproofing membrane to such surfaces can effectively extend their lifespan and shield them against potential water-induced damage, such as corrosion or deterioration. Therefore, it is essential to carefully choose a waterproofing membrane that is compatible with zinc and meticulously adhere to the manufacturer's instructions regarding proper application and maintenance.

- Q: Can waterproofing membranes be used on concrete countertops?

- Concrete countertops can indeed benefit from the application of waterproofing membranes. These membranes are specially crafted to thwart the infiltration of water and can be utilized on diverse surfaces, including concrete. By opting for a waterproofing membrane on a concrete countertop, one can effectively safeguard it against water harm, staining, and possible structural concerns. Furthermore, these membranes can augment the countertop's resilience and lifespan by averting moisture-induced problems, such as cracking or warping. It is imperative to verify that the selected waterproofing membrane is concrete-compatible and appropriate for countertop use.

- Q: Can a waterproofing membrane be used on tunnels with security systems?

- Yes, a waterproofing membrane can be used on tunnels with security systems. In fact, it is highly recommended to use a waterproofing membrane in tunnels, especially those with security systems, to protect the infrastructure and valuable equipment from water damage. Waterproofing membranes are designed to prevent water infiltration, providing a protective barrier against water leakage and potential moisture-related issues such as corrosion, mold growth, and structural deterioration. By using a waterproofing membrane in tunnels with security systems, the integrity of the tunnel structure and the functionality of the security systems can be preserved, ensuring the safety and security of the facility.

- Q: Can waterproofing membranes be used on parking decks?

- Yes, waterproofing membranes can be used on parking decks. Parking decks are exposed to various weather conditions and are subject to constant vehicle traffic, which can lead to water penetration and damage. Waterproofing membranes provide a protective barrier against water infiltration, preventing moisture from seeping into the structure and causing deterioration. These membranes are designed to withstand heavy loads and resist the chemicals found in automotive fluids, making them an ideal solution for parking decks. By applying waterproofing membranes, the lifespan of the parking deck can be extended, reducing the need for costly repairs and ensuring the safety and integrity of the structure.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Yes, waterproofing membranes can be used on stormwater management systems. These membranes provide a protective barrier that prevents water from infiltrating into the system, ensuring efficient and reliable stormwater management.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Using a waterproofing membrane comes with its fair share of drawbacks and limitations. One issue is the time-consuming and labor-intensive installation process. These membranes require careful surface preparation and multiple layers, which can be both time-consuming and require skilled labor. As a result, the overall cost of the project may increase. Another limitation is that not all surfaces are suitable for waterproofing membranes. Certain membranes are designed for specific types of substrates, such as concrete or metal, and may not adhere properly to other materials. To ensure proper adhesion and effectiveness, it is crucial to select the appropriate type of membrane for the specific surface. Moreover, waterproofing membranes can be sensitive to environmental conditions. Exposure to extreme temperature fluctuations, UV rays, and chemicals can degrade the membrane over time, reducing its effectiveness. To ensure the longevity of the membrane, regular inspections and maintenance may be necessary. Furthermore, during installation or due to external factors such as foot traffic or heavy objects, waterproofing membranes can be susceptible to damage. Punctures, tears, or improper installation can compromise the integrity of the membrane and reduce its ability to prevent water infiltration. Lastly, in certain situations, waterproofing membranes may not completely prevent water penetration. If there are existing cracks or structural issues in the substrate, water may find a way to seep through, bypassing the membrane. Therefore, it is important to address any underlying structural issues before applying the membrane to ensure optimal performance. In conclusion, while waterproofing membranes offer significant benefits in terms of water damage protection, it is crucial to consider these limitations and drawbacks before deciding to use them in specific applications.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Precast metal surfaces can benefit from the application of a waterproofing membrane. These membranes are specifically designed to create a protective layer that stops water from penetrating the surface. They can be used on various types of surfaces, including precast metal. Waterproofing membranes are typically made from materials like bitumen, liquid coatings, or synthetic rubber. These materials form a barrier that prevents water and moisture from causing damage. When a waterproofing membrane is applied to precast metal surfaces, it helps to prevent corrosion, protects against water damage, and improves the overall durability and lifespan of the metal structure. However, it is crucial to select a waterproofing membrane that is compatible with the specific type of precast metal surface. Additionally, proper surface preparation and application techniques must be followed to ensure optimal performance.

Send your message to us

EPDM Waterproofing Roofing Membrane with 1.2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords