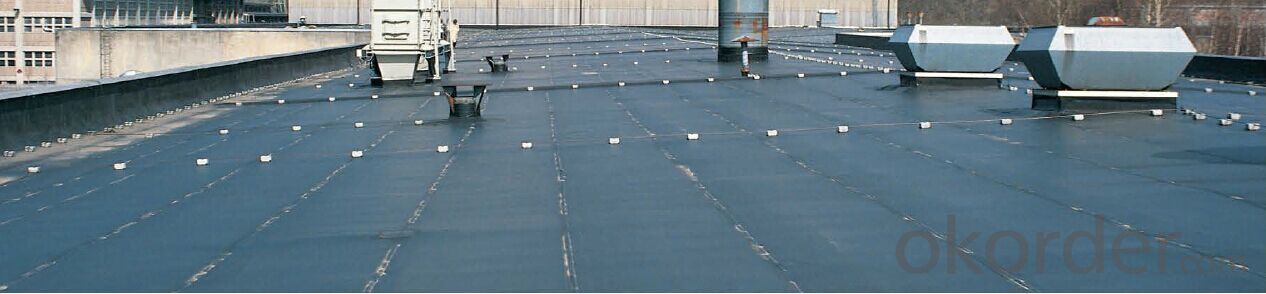

EPDM Rubber Roofing Membrane 1.5 mm with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Roofing Membrane Applications:

1. Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

EPDM Rubber Roofing Membrane Features:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

EPDM Rubber Roofing Membrane Advantages:

1. High elasticity among high polymer waterproof materialsand becomes a world-popular waterproofing material.

2. Adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

EPDM Rubber Roofing Membrane Specifications:

1. Material: EPDM Rubber

2. Size: 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width

3. Thick: 1.2mm, 1.5mm, 2.0mm

4. Type: Vulcanized & Weldable

5. Pattern: Non-reinforced (homogeneous)

6. Certificate: ISO9001/14001

FAQ:

Q: Can I visit your company?

A: Yes, welcome to visit our enterprise.

Q: Can I do the third party testing before loading?

A: Yes, we could accept the third party testing.

Q: Which kind of payment in your company?

A: We could accept TT, LC at sight, etc.

- Q: Are there different waterproofing membrane options for above-ground and below-ground applications?

- Yes, there are different waterproofing membrane options available for above-ground and below-ground applications. Above-ground applications typically involve waterproofing structures such as roofs, balconies, or walls. For these applications, commonly used waterproofing membrane options include liquid-applied membranes, sheet membranes, and polyurethane membranes. These membranes are designed to withstand exposure to weather elements such as UV rays, temperature changes, and foot traffic. On the other hand, below-ground applications involve waterproofing structures like basements, foundations, or tunnels. Below-ground waterproofing membranes are specifically designed to withstand hydrostatic pressure from the surrounding soil and groundwater. These membranes are typically thicker and more durable than above-ground membranes. Commonly used below-ground waterproofing options include bituminous membranes, bentonite clay membranes, and composite membranes. It is important to choose the right waterproofing membrane for each specific application as the requirements and challenges can vary. Consulting with a waterproofing professional or engineer can help determine the most suitable membrane option for both above-ground and below-ground applications.

- Q: What is the purpose of a waterproofing membrane?

- The purpose of a waterproofing membrane is to protect buildings and structures from water infiltration and damage. It is designed to create a barrier that prevents water from penetrating into the interior spaces or causing structural deterioration. Waterproofing membranes are commonly used in areas such as basements, roofs, walls, and foundations, where water intrusion is a common concern. By effectively sealing surfaces and preventing moisture penetration, a waterproofing membrane helps to maintain the integrity and longevity of a structure. Additionally, it helps to prevent the growth of mold and mildew, which can be harmful to both the building and its occupants. Overall, the purpose of a waterproofing membrane is to ensure the durability, safety, and longevity of a structure by providing effective protection against water damage.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, a waterproofing membrane can be used in areas with extreme weather conditions, such as hurricanes or snowstorms. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively withstand various weather conditions. They are made from materials that are resistant to moisture and can be installed in different areas like roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes can help prevent water damage by creating a barrier that keeps water out even during heavy rainfall or storm surges. These membranes are often reinforced and have high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas with heavy snowstorms, waterproofing membranes can help prevent water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring that they maintain their integrity and prevent leaks even in freezing conditions. However, it is important to choose the right type of waterproofing membrane suitable for the specific weather conditions in the area. Different membranes have varying levels of resistance to extreme weather, so it is advisable to consult with a professional to determine the most appropriate membrane for the specific climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: Can a waterproofing membrane be used for both interior and exterior applications?

- Yes, a waterproofing membrane can be used for both interior and exterior applications.

- Q: Can a waterproofing membrane be applied over existing waterproofing layers?

- Yes, a waterproofing membrane can be applied over existing waterproofing layers. However, it is important to assess the condition of the existing layers to ensure they are sound and can provide a proper substrate for the new membrane. Additionally, proper surface preparation and compatibility between the existing layers and the new membrane should be considered to ensure a successful and long-lasting waterproofing system.

- Q: Are waterproofing membranes resistant to battery acid?

- Waterproofing membranes do not usually possess the necessary resistance against battery acid. Their main function is to create a barrier against water and moisture, and they are typically composed of materials like bitumen, rubber, or modified asphalt. Although these materials may exhibit some level of acid resistance, they are not typically engineered to endure the corrosive nature of battery acid. Battery acid, commonly sulfuric acid, can inflict substantial harm on various materials, including waterproofing membranes. If you are dealing with battery acid or find yourself in a situation where exposure to battery acid is a concern, it is advisable to employ materials specifically designed to withstand the corrosive effects of battery acid or seek professional assistance for appropriate solutions.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to protect surfaces from water penetration and damage. They are typically made of materials such as rubber, asphalt, or thermoplastic, which provide a barrier against moisture. Whether it is applied on interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane can effectively prevent water from seeping through and causing potential issues like leaks, mold, or structural damage. It is important to consider the specific requirements of each surface and choose a waterproofing membrane that is suitable for the intended application.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer serves multiple purposes. Firstly, it helps to prevent damage to the waterproofing membrane during and after installation. It acts as a barrier against sharp objects, construction debris, and potential punctures. Additionally, the protective layer helps to distribute loads evenly and provide stability to the membrane, reducing the risk of damage caused by foot traffic or heavy equipment. Furthermore, the protective layer serves as a UV barrier, shielding the waterproofing membrane from the harmful effects of sunlight exposure. UV rays can degrade the membrane over time, leading to reduced effectiveness and potential leaks. The protective layer also helps to regulate temperature fluctuations, which can expand and contract the membrane, causing stress and compromising its waterproofing capabilities. In summary, a protective layer is essential for the longevity and performance of a waterproofing membrane. It safeguards against physical damage, UV radiation, and temperature fluctuations, ensuring the membrane's effectiveness in keeping water out and preserving the integrity of the structure it protects.

- Q: Can a waterproofing membrane be used in conjunction with vapor barriers?

- Using both a waterproofing membrane and vapor barriers together is highly recommended to provide thorough protection against moisture. Waterproofing membranes effectively block water from penetrating surfaces like roofs or foundations, while vapor barriers prevent the passage of water vapor. By utilizing both, you can prevent both liquid water and water vapor from causing any harm to a structure. The waterproofing membrane acts as a physical barrier, ensuring that water cannot enter, while the vapor barrier stops moisture buildup within the structure. This combination is especially advantageous in regions with high humidity or areas at risk of water intrusion.

- Q: Can waterproofing membranes be used on elevator pits?

- Yes, waterproofing membranes can be used on elevator pits. Elevator pits are prone to water infiltration due to their location below ground level, making them susceptible to water damage and leaks. Waterproofing membranes provide an effective solution to prevent water penetration and protect elevator pits from moisture-related issues. These membranes are designed to create a watertight barrier, usually made of materials such as rubber, polyurethane, or bitumen. They are applied to the walls and floor of the elevator pit, forming a seamless and durable protective layer. This membrane system helps to keep the pit dry, preventing water damage to the elevator components and ensuring the safe and reliable operation of the elevator.

Send your message to us

EPDM Rubber Roofing Membrane 1.5 mm with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords