EPDM Rubber Roofing Membrane 1.2 mm with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

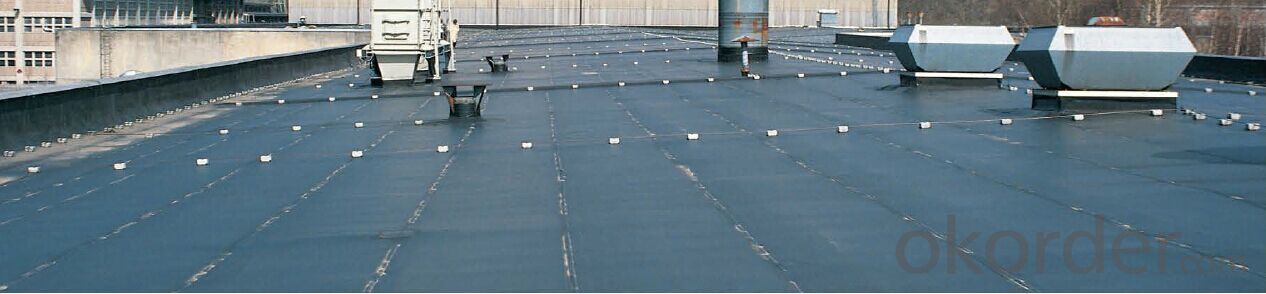

EPDM Rubber Roofing Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

Product Applications:

1. Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

Product Features:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Product Advantages:

1. High elasticity among high polymer waterproof materialsand becomes a world-popular waterproofing material.

2. Adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

Product Specifications:

1. Material: EPDM Rubber

2. Size: 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width

3. Thick: 1.2mm, 1.5mm, 2.0mm

4. Type: Vulcanized & Weldable

5. Pattern: Non-reinforced (homogeneous)

6. Certificate: ISO9001/14001

FAQ:

Q: Can I visit your company?

A: Yes, welcome to visit our enterprise.

Q: Can I do the third party testing before loading?

A: Yes, we could accept the third party testing.

Q: Which kind of payment in your company?

A: We could accept TT, LC at sight, etc.

- Q: Can a waterproofing membrane be used on exterior walls?

- Yes, a waterproofing membrane can be used on exterior walls. It is commonly used to prevent moisture penetration and protect the building envelope from water damage.

- Q: What are the benefits of using a waterproofing membrane?

- There are several benefits of using a waterproofing membrane, especially in construction projects or areas that are exposed to moisture or water. Firstly, a waterproofing membrane helps to prevent water penetration, which is crucial in protecting the structural integrity of a building or infrastructure. Water can seep through cracks or joints, causing damage to the foundation, walls, or floors. By applying a waterproofing membrane, it creates a barrier that prevents water from infiltrating and causing potential structural issues. Secondly, waterproofing membranes can help to prevent the growth of mold and mildew. Moisture and excess water can create a breeding ground for mold, which not only damages the aesthetics of a space but also poses health risks. By using a waterproofing membrane, it keeps moisture out and reduces the chances of mold growth, creating a healthier and safer environment. Additionally, a waterproofing membrane can help to increase the lifespan of a structure. By preventing water intrusion, it protects the building materials from deterioration caused by moisture. This can save on repair and maintenance costs in the long run, as the structure remains in good condition for a longer period of time. Furthermore, waterproofing membranes can also contribute to energy efficiency. By sealing off any gaps or cracks, it helps to retain heat or cool air inside a building, reducing energy consumption and improving insulation. This can lead to significant energy savings and lower utility bills. Lastly, using a waterproofing membrane can provide peace of mind. Knowing that a building or structure is protected from water damage, mold growth, and potential structural issues brings a sense of security and confidence, particularly in areas prone to heavy rainfall, flooding, or high moisture levels. In conclusion, the benefits of using a waterproofing membrane are numerous. It protects against water damage, prevents mold growth, increases the lifespan of a structure, improves energy efficiency, and provides peace of mind. Whether it is for residential, commercial, or industrial purposes, incorporating a waterproofing membrane is a wise investment that ensures the longevity and durability of a building or infrastructure.

- Q: How does a waterproofing membrane handle differential settlement?

- The purpose of a waterproofing membrane is to prevent water infiltration and protect the underlying structure from moisture damage. However, the performance of the membrane can be affected when dealing with differential settlement. Differential settlement refers to uneven settling of the ground or building foundation, which can result in variations in height or level within the structure. This can cause stress and movement in the building, potentially impacting the waterproofing membrane. To address differential settlement, waterproofing membranes are designed to be flexible and capable of accommodating minor movements without compromising their effectiveness. They are often made from materials like modified bitumen, polyurethane, or rubberized asphalt, which have inherent elasticity and can stretch or contract to a certain degree. In cases of minor differential settlement within the membrane's tolerances, it can adjust and remain intact, maintaining its waterproofing capabilities. However, significant settlement or movement beyond the membrane's flexibility may cause cracks or tears, leading to potential water leakage. To minimize the impact of differential settlement, additional measures can be taken during membrane installation. This may involve incorporating stress-relieving elements like expansion joints or utilizing specialized installation techniques that allow for movement. These measures help distribute the stress caused by settlement and reduce strain on the waterproofing membrane. It is important to note that while waterproofing membranes can handle some level of differential settlement, they are not a solution for structural issues or significant settlement problems. In cases of severe settlement, it is crucial to address the underlying cause and potentially involve a structural engineer to determine appropriate remediation measures. In conclusion, a waterproofing membrane can accommodate minor movements caused by differential settlement through its flexibility. However, considering the severity of settlement and implementing additional measures during installation is crucial for ensuring the long-term effectiveness of the waterproofing system.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- Yes, a waterproofing membrane can have an impact on the appearance of a surface. Depending on the type and application method of the membrane, it may add a layer of protection that alters the texture, sheen, or color of the surface. Additionally, some membranes may be visible or create a slightly raised or textured effect on the surface. However, there are also transparent or thin membranes available that have minimal impact on the appearance of the surface.

- Q: How does a waterproofing membrane handle movement joints or cracks?

- A waterproofing membrane is designed to accommodate movement joints or cracks by providing flexibility and elasticity. It can stretch and contract to accommodate the movement of the substrate, ensuring that water does not penetrate through the joints or cracks. Additionally, some waterproofing membranes have the ability to self-heal small cracks, further enhancing their effectiveness in handling movement joints or cracks.

- Q: Can a waterproofing membrane be used in food processing or pharmaceutical facilities?

- Yes, a waterproofing membrane can be used in food processing or pharmaceutical facilities. Waterproofing membranes are commonly used in these types of facilities to ensure that the surrounding environment remains dry and free from water damage. They create a protective barrier against moisture, preventing leaks and water penetration. This is particularly important in food processing and pharmaceutical facilities where hygiene and cleanliness are crucial. Waterproofing membranes can be applied to various surfaces such as floors, walls, and ceilings, ensuring that all areas are adequately protected. Additionally, these membranes are often made from materials that are resistant to chemicals and bacteria growth, further enhancing their suitability for use in these sensitive environments. Overall, utilizing a waterproofing membrane in food processing or pharmaceutical facilities is an effective way to maintain a dry and safe environment for the production of quality products.

- Q: Can a waterproofing membrane be used in hot climates?

- Yes, a waterproofing membrane can be used in hot climates. In fact, it is essential to use a waterproofing membrane in areas with high temperatures and intense sunlight. The membrane provides protection against water intrusion, which is crucial in preventing damage to structures such as roofs, balconies, or basements. Additionally, a high-quality waterproofing membrane is designed to withstand the effects of temperature fluctuations and UV radiation, ensuring its longevity and effectiveness even in hot climates. Therefore, using a waterproofing membrane is highly recommended in hot climates to ensure the durability and integrity of the structures it is applied to.

- Q: How does a waterproofing membrane handle water infiltration through cracks or gaps?

- By forming a seamless barrier, a waterproofing membrane effectively addresses the issue of water infiltration through cracks or gaps. Typically constructed from durable and flexible materials like rubber, PVC, or modified bitumen, the membrane possesses the ability to withstand the movement and expansion of the underlying structure. When encountering a crack or gap on the surface, the membrane acts as a seal, halting the water from progressing further. The material utilized in the membrane is impervious to water, signifying that it does not permit water molecules to permeate its surface. Furthermore, the membrane is installed in a manner that encompasses the entire surface area, including any existing cracks or gaps. This guarantees the absence of vulnerable points in the waterproofing system, preventing water infiltration. Additionally, the membrane is designed to possess flexibility. This adaptability enables it to accommodate any movement or shifting of the underlying structure without compromising its ability to repel water. This quality proves particularly crucial in areas where cracks or gaps may emerge as a result of natural settling or movement of the building. All in all, a waterproofing membrane capably manages water infiltration through cracks or gaps by providing an uninterrupted, impenetrable barrier that obstructs water from penetrating the structure. It represents a dependable solution for safeguarding buildings and structures from water damage and preserving their integrity over time.

- Q: Can a waterproofing membrane be used for a parking garage?

- Indeed, a parking garage can benefit greatly from the utilization of a waterproofing membrane. Specifically designed to act as a barrier against water infiltration, this membrane effectively safeguards the underlying structure from potential moisture damage. Given the frequent exposure to water and moisture in parking garages due to rain, snow, and vehicle fluids, incorporating a waterproofing membrane is a vital aspect of the building envelope system. Its application on various concrete surfaces, such as the floor and walls, effectively prevents water seepage and subsequently hinders the occurrence of deterioration, corrosion, or any form of harm to the parking garage's structural integrity. Moreover, a waterproofing membrane also serves to mitigate the development of efflorescence, mold, and mildew, all of which are commonly found in damp environments. In conclusion, the implementation of a waterproofing membrane within a parking garage is an efficient approach to ensure the structure's long-term durability and functionality.

- Q: Can a waterproofing membrane be used for swimming pool decks or patios?

- Certainly, swimming pool decks or patios can absolutely benefit from the utilization of a waterproofing membrane. These specialized membranes are specifically engineered to establish a protective barrier that prevents water infiltration, thus averting potential harm to the surface. Various surfaces, including concrete, wood, and stone, can be effectively waterproofed by employing these membranes. By applying a waterproofing membrane to swimming pool decks or patios, the underlying structure can be shielded against water-induced damage, such as cracks, mold, and wear. Furthermore, these membranes also offer slip resistance, which is a crucial safety feature for areas surrounding swimming pools. Overall, the application of a waterproofing membrane is a reliable and efficient approach to safeguarding and extending the lifespan of swimming pool decks and patios.

Send your message to us

EPDM Rubber Roofing Membrane 1.2 mm with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords