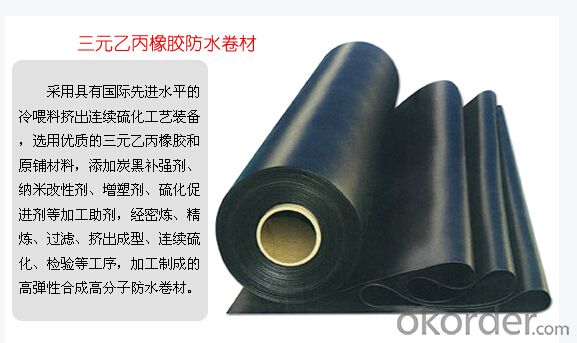

EPDM Pond Liner/Roofing Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

2.Product Technicial Data for EPDM Waterproof Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

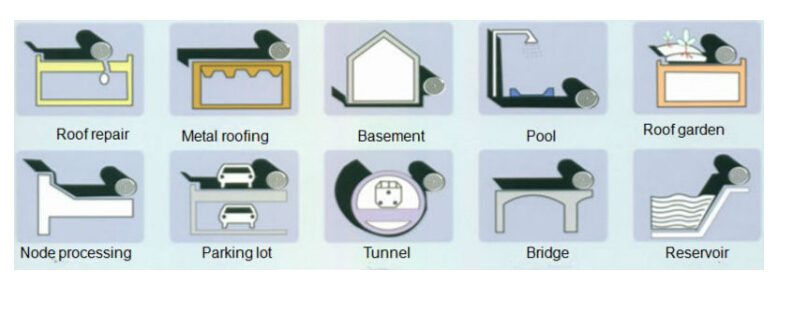

3. Product Application:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

4. Some photos:

- Q: Is a waterproofing membrane resistant to algae or moss growth?

- Yes, a waterproofing membrane is typically resistant to algae or moss growth. The materials used in waterproofing membranes are designed to prevent the growth of organic matter, including algae and moss.

- Q: Can a waterproofing membrane be applied on any surface?

- A waterproofing membrane can be applied on a variety of surfaces, but it is important to consider the specific characteristics and requirements of each surface before proceeding. While many waterproofing membranes are versatile and can adhere to different materials, it is recommended to consult with a professional or manufacturer to ensure compatibility and optimal performance. For concrete surfaces, waterproofing membranes can be applied to prevent water penetration and protect against moisture damage. These membranes are typically designed to adhere to concrete and provide a barrier against water and vapor transmission. However, it is important to properly prepare the concrete surface by cleaning, repairing any cracks or imperfections, and ensuring a smooth and even substrate for the membrane. Similarly, waterproofing membranes can be applied to masonry surfaces such as brick or stone. These surfaces may require additional preparation, such as removing loose mortar or debris, and may benefit from a primer to enhance adhesion. Additionally, certain types of waterproofing membranes may be more suitable for these surfaces depending on their porosity and texture. Waterproofing membranes can also be applied to wood surfaces, such as decks or balconies, to protect against moisture damage and extend their lifespan. However, it is important to select a membrane specifically designed for wood surfaces as they may require additional flexibility to accommodate the natural movement and expansion of the wood. In summary, while a waterproofing membrane can be applied on various surfaces, it is crucial to consider the specific characteristics and preparation requirements of each surface to achieve optimal results. Consulting with a professional or manufacturer can help determine the most suitable membrane and application method for a particular surface.

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. These requirements may vary depending on the type of membrane being used and the specific application. However, some general requirements include: 1. Surface Preparation: The surface where the membrane will be installed must be clean, dry, and free from any dust, debris, or contaminants. Any cracks or defects in the surface should be repaired prior to installation. 2. Adhesive or Bonding Agent: Depending on the type of membrane, an adhesive or bonding agent may be required to ensure proper adhesion to the substrate. This adhesive should be compatible with both the membrane and the substrate. 3. Primer: In some cases, a primer may be necessary to enhance the adhesion between the substrate and the membrane. The type of primer required will depend on the specific membrane and substrate being used. 4. Seam and Joint Preparation: Properly preparing seams and joints is crucial to ensure a watertight installation. This may involve using a specific sealant or tape to reinforce the seams and prevent water penetration. 5. Installation Techniques: The membrane should be installed according to the manufacturer's instructions and industry best practices. This may include using a specific method such as torching, hot air welding, or cold adhesive application. 6. Overlaps and Transitions: Properly overlapping the membrane sheets and ensuring smooth transitions between different areas is essential for a successful installation. This will help prevent water from seeping through gaps or weak points in the membrane. 7. Quality Control: Regular inspections and quality control measures should be implemented throughout the installation process to ensure that the membrane is being installed correctly and meets the required standards. It is important to consult the manufacturer's guidelines and specifications for the specific waterproofing membrane being used, as different membranes may have unique installation requirements. Additionally, local building codes and regulations should also be considered to ensure compliance and to meet any specific requirements in your area.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Metal block surfaces can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to form a barrier against water and moisture, and they are versatile enough to be applied to various types of surfaces, including metal. By adhering to the metal surface, the membrane creates a protective layer that not only prevents water infiltration but also safeguards the metal against rust and corrosion. However, it is crucial to guarantee that the metal surface is thoroughly cleaned, dried, and appropriately prepared before the application of the waterproofing membrane. This preparation ensures optimal adhesion and effectiveness. For specific instructions on using a waterproofing membrane on metal block surfaces, it is highly recommended to consult a professional or refer to the manufacturer's guidelines.

- Q: Can a waterproofing membrane be used on swimming pools?

- Indeed, swimming pools can utilize a waterproofing membrane. It is a prevalent and efficient technique to guarantee the pool's impermeability. Normally composed of PVC or rubber, waterproofing membranes are specially crafted to obstruct water infiltration through the pool's walls or floor. They are applied as a fine layer or sheet across the pool's surfaces, forming a barrier that confines the water within. This approach diminishes the likelihood of leaks and water-related harm, safeguarding the longevity and functionality of the pool.

- Q: Can a waterproofing membrane be used for a bridge?

- Yes, a waterproofing membrane can be used for a bridge. A waterproofing membrane is a specially designed material that is used to prevent the penetration of water into structures, such as bridges. It is typically applied to the surface of the bridge deck and provides a continuous barrier against water infiltration. This is especially important for bridges, as they are constantly exposed to environmental elements like rain, snow, and moisture. The waterproofing membrane helps to protect the bridge deck and underlying concrete from moisture damage, which can lead to deterioration and structural issues over time. By preventing water penetration, it helps to extend the lifespan of the bridge and reduce the need for costly repairs. Additionally, the waterproofing membrane can also improve the overall durability and performance of the bridge by reducing the potential for corrosion of reinforcing steel and preventing the ingress of harmful chemicals. Overall, the use of a waterproofing membrane is highly recommended for bridges to ensure their long-term functionality and structural integrity.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- A waterproofing membrane is capable of protecting against the growth of mold or mildew, as they thrive in environments that are damp and moist. The membrane acts as a barrier, preventing water from entering the building structure. This effectively keeps the area dry and greatly reduces the likelihood of mold or mildew growth. Furthermore, waterproofing membranes often contain anti-microbial properties that further hinder the growth of mold and mildew. Nevertheless, it is important to remember that while a waterproofing membrane can offer substantial protection against mold and mildew, it is not a foolproof solution. It is crucial to ensure proper ventilation and carry out regular maintenance to prevent these issues.

- Q: Can a waterproofing membrane be used for railways or train stations?

- Yes, a waterproofing membrane can definitely be used for railways or train stations. Waterproofing membranes are commonly used in various construction projects to protect structures from water damage and ensure their longevity. In the case of railways and train stations, where there is constant exposure to weather elements and potential water infiltration, a waterproofing membrane can play a crucial role in preventing water ingress into the infrastructure. Waterproofing membranes are typically applied to different areas of the railway or train station, such as the underground tunnels, platforms, parking areas, and even the roofs. These membranes are designed to create a barrier against water and moisture, preventing them from seeping into the structure and causing damage. By preventing water infiltration, a waterproofing membrane helps to maintain the structural integrity of the railway or train station and extend its lifespan. In addition to protecting against water, waterproofing membranes also provide other benefits such as preventing the growth of mold and mildew, improving energy efficiency by reducing heat loss, and enhancing the overall durability of the structure. They are available in various types, including liquid-applied membranes, sheet membranes, and cementitious coatings, allowing for versatile application depending on the specific needs and requirements of the railway or train station project. Overall, the use of a waterproofing membrane in railways and train stations is highly recommended to ensure the long-term performance and maintenance of these critical infrastructures.

- Q: Is a waterproofing membrane resistant to saltwater or other corrosive substances?

- Waterproofing membranes, in general, have the ability to resist saltwater and other substances that cause corrosion. These membranes are created to act as a barrier against moisture and water intrusion, offering protection against corrosive agents. The materials commonly used to manufacture these membranes, such as modified bitumen, PVC, EPDM, or TPO, naturally possess resistance to saltwater and other corrosive elements. Some manufacturers may even add extra layers or coatings to further enhance the membrane's ability to resist corrosive substances. Nevertheless, it is important to consider that the degree of resistance can vary depending on the specific type and quality of the waterproofing membrane employed. Therefore, it is crucial to select a high-quality membrane that is specifically designed for the intended application, whether it be in saltwater environments or areas exposed to other corrosive substances.

- Q: Can waterproofing membranes be used on roofs?

- Yes, waterproofing membranes can be used on roofs. These membranes are designed to provide a barrier against water infiltration, protecting the roof structure and preventing leaks. They are commonly used in various types of roofs, including flat roofs, low-slope roofs, and even sloped roofs in certain cases. Waterproofing membranes offer excellent durability and flexibility, making them an effective solution for roof waterproofing.

Send your message to us

EPDM Pond Liner/Roofing Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords