EPDM Weldable Waterproof Membrane for Pond Liner Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features for EPDM Waterproof Membrane

1)the excellent anti-aging, in the long term light, humidity, cold use of the natural environment, small changes in physical properties, used in temperature from -50 degree to 80 degree.

2)with outstanding ozone resistance, resistance to ultraviolet and atmospheric corrosion of many chemical corrosive substances.

3) high tensile strength, high elongation, high flexibility, capable of sustaining a puncture of hard material, good anti-crack, high adaptbility of the grass roots contraction and the crack and deformation, and give full play to extend the performance, playing the role of waterproofing.

4)long lifetime, high durability can achieve more than 25 years.

5)the cold construction operation, no environment pollution and simple operation.

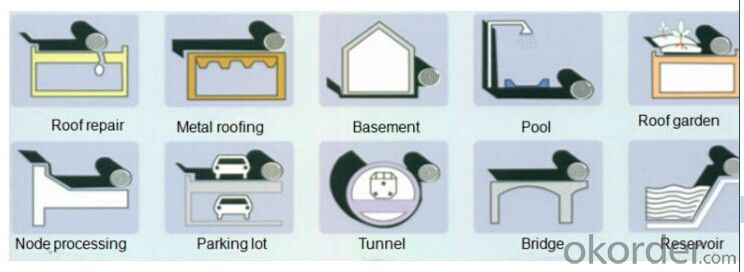

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

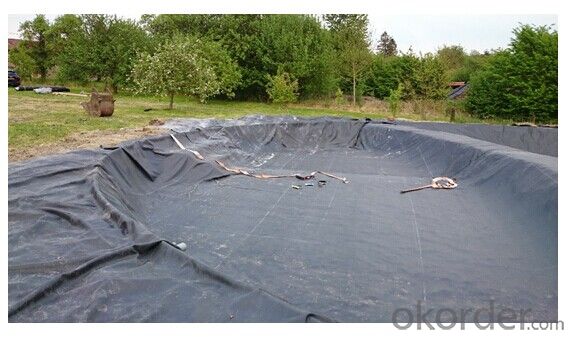

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Type | EPDM |

Material | EPDM Rubber |

Thickness | 1.2mm,1.5mm,2.0mm |

Length | 20m/roll |

Width | 1.2m |

Usage | roof/walls/bathroom/tunnel/basement/bridge/road/underground, |

Application method | Hot melt |

Length | 20m |

Surface | Smooth surface,fleece surface |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on glass surfaces?

- Using a different grammar and expressions: It is not possible to utilize a waterproofing membrane on glass surfaces. Waterproofing membranes are specifically formulated to adhere to surfaces that are porous and rough, such as concrete, wood, or metal. Glass surfaces, on the other hand, are smooth and non-porous, which poses challenges for proper adhesion of the membrane and its ability to establish an effective waterproof barrier. Furthermore, glass surfaces are inherently waterproof, rendering additional waterproofing measures generally unnecessary.

- Q: Can a waterproofing membrane be used in swimming pools or other water features?

- Certainly, swimming pools or other water features can indeed utilize a waterproofing membrane. In fact, it is highly advisable to employ such a membrane in these areas to avert water leakage and potential harm. By serving as a barrier between the water and the surrounding structures, a waterproofing membrane ensures that the water remains contained within the pool or water feature. Not only does it prevent water seepage, which can inflict structural damage and necessitate expensive repairs, but it also safeguards the pool or water feature from the harsh chemicals employed for water treatment, thereby guaranteeing its durability and long lifespan. Consequently, the utilization of a waterproofing membrane is an essential measure in the construction or renovation of swimming pools or other water features, guaranteeing their functionality and longevity.

- Q: Can a waterproofing membrane be used in elevator pits?

- Yes, a waterproofing membrane can be used in elevator pits. Elevator pits are prone to water intrusion, as they are located underground and can be exposed to groundwater or other sources of moisture. A waterproofing membrane is a protective layer that is applied to the walls and floor of the elevator pit to prevent water from seeping through. It acts as a barrier and prevents water damage to the structural components of the elevator system, such as the electrical equipment, pumps, and hydraulic systems. By using a waterproofing membrane in elevator pits, the risk of water damage and corrosion can be significantly reduced, ensuring the safe and efficient operation of the elevator.

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Yes, a waterproofing membrane can be used on tunnels with subway systems. In fact, it is highly recommended to install a waterproofing membrane in subway tunnels to prevent water infiltration and potential damage to the structure and electrical systems. The waterproofing membrane acts as a barrier to keep water out and protect the tunnel from moisture-related issues such as corrosion, mold, and deterioration. It is important to choose a waterproofing membrane that is specifically designed for tunnel applications and can withstand the unique conditions and challenges of subway systems, such as high traffic loads, vibrations, and exposure to chemicals. Additionally, the installation of the waterproofing membrane should be done by experienced professionals following the appropriate guidelines and specifications to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- A waterproofing membrane is capable of protecting against the growth of mold or mildew, as they thrive in environments that are damp and moist. The membrane acts as a barrier, preventing water from entering the building structure. This effectively keeps the area dry and greatly reduces the likelihood of mold or mildew growth. Furthermore, waterproofing membranes often contain anti-microbial properties that further hinder the growth of mold and mildew. Nevertheless, it is important to remember that while a waterproofing membrane can offer substantial protection against mold and mildew, it is not a foolproof solution. It is crucial to ensure proper ventilation and carry out regular maintenance to prevent these issues.

- Q: Does a waterproofing membrane have any impact on the thermal performance of a structure?

- Yes, a waterproofing membrane can have an impact on the thermal performance of a structure. A waterproofing membrane is typically used in buildings to prevent water infiltration, which can cause damage to the structure over time. By creating a barrier against moisture, the membrane helps to maintain the integrity of the building envelope and protect against potential leaks or water damage. In terms of thermal performance, a waterproofing membrane can help to improve insulation by reducing the amount of heat transfer through the building envelope. By preventing moisture from entering the structure, the membrane also helps to prevent the formation of condensation, which can lead to mold growth and further damage to the building materials. Furthermore, some waterproofing membranes are designed with additional insulation properties, such as foam or reflective coatings, which can further enhance the thermal performance of a structure. These membranes help to reduce thermal bridging and improve energy efficiency by minimizing heat loss or gain through the building envelope. It is important to note that the impact of a waterproofing membrane on the thermal performance of a structure can vary depending on the specific type of membrane, its installation, and the overall design of the building. It is advisable to consult with a professional architect or engineer to determine the most suitable waterproofing solution that meets both the water resistance and thermal performance requirements for a particular structure.

- Q: What is the cost of installing a waterproofing membrane?

- The cost of installing a waterproofing membrane can vary depending on several factors such as the size of the area to be waterproofed, the type of membrane used, and the complexity of the installation. On average, the cost can range from $3 to $10 per square foot. However, it is recommended to obtain quotes from professional contractors to get an accurate estimate for your specific needs.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. Terraces and patios are exposed to various weather conditions, including rain and snow, which can lead to moisture seeping into the underlying structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the surface and protecting the integrity of the terrace or patio. It helps to extend the lifespan of the structure and prevents costly repairs in the long run. Additionally, using a waterproofing membrane also helps to create a more comfortable and usable space, as it eliminates the risk of water accumulation and potential slip hazards. Overall, investing in a high-quality waterproofing membrane is a wise decision for anyone looking to protect their terrace or patio from water damage.

- Q: How is the water level rated and how many grades are used?

- 1, roof waterproof level 1: Application: particularly important or waterproof with special requirements of the building; Waterproof layer of reasonable use of life: 25 years; Waterproof layer selection of materials: should use synthetic polymer waterproofing membrane, polymer modified asphalt waterproofing membrane, metal sheet, synthetic polymer waterproof coating, fine stone concrete and other materials; Fortification requirements: three or more than three waterproof fortification.

- Q: Can a waterproofing membrane be used in geotechnical applications?

- Yes, a waterproofing membrane can be used in geotechnical applications. It is commonly used to prevent water infiltration in structures such as tunnels, retaining walls, and basements. The membrane acts as a barrier, effectively sealing the structure and protecting it from water damage.

Send your message to us

EPDM Weldable Waterproof Membrane for Pond Liner Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords