EPDM roof /pond/basement waterproof membrane manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

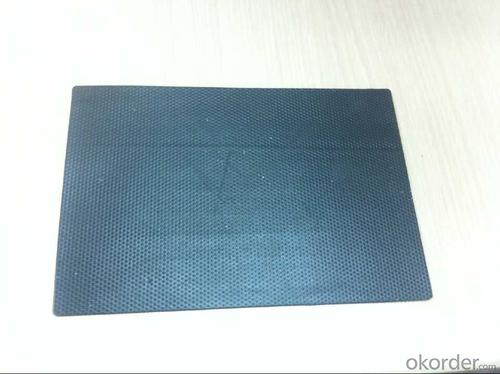

EPDM Coiled Rubber Waterproof Membrane for Ponds

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

IMages of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used on brass surfaces?

- A waterproofing membrane is typically used to protect surfaces from water penetration and damage. While brass surfaces are not typically prone to water damage, a waterproofing membrane can still be used as an additional protective layer. It can help prevent moisture build-up on the brass surface, which can eventually lead to tarnishing or corrosion. However, it is important to note that brass surfaces are often desired for their natural patina and aesthetic appeal. Applying a waterproofing membrane may alter the appearance of the brass, potentially creating a glossy or artificial finish. Therefore, it is advisable to carefully consider the desired outcome before deciding to use a waterproofing membrane on brass surfaces.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Yes, a waterproofing membrane can be used for residential buildings or homes. Waterproofing membranes are commonly used in construction to prevent water penetration and protect the building's structure and interior from moisture damage. They can be applied to various areas such as basements, roofs, foundations, and bathrooms, among others. By creating a barrier against water, these membranes help to prevent leaks, mold growth, and damage to the building materials. Therefore, using a waterproofing membrane is an effective way to ensure the longevity and durability of residential buildings or homes.

- Q: Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

- Q: How does a waterproofing membrane handle water pressure from adjacent structures?

- A waterproofing membrane is designed to handle water pressure from adjacent structures by acting as a barrier that prevents water from seeping through. It resists the force exerted by the water pressure and ensures that no water can penetrate into the protected area.

- Q: Can a waterproofing membrane be used on tunnels with security systems?

- Yes, a waterproofing membrane can be used on tunnels with security systems. In fact, it is highly recommended to use a waterproofing membrane in tunnels, especially those with security systems, to protect the infrastructure and valuable equipment from water damage. Waterproofing membranes are designed to prevent water infiltration, providing a protective barrier against water leakage and potential moisture-related issues such as corrosion, mold growth, and structural deterioration. By using a waterproofing membrane in tunnels with security systems, the integrity of the tunnel structure and the functionality of the security systems can be preserved, ensuring the safety and security of the facility.

- Q: Can waterproofing membranes be used on parking decks?

- Indeed, parking decks can benefit from the application of waterproofing membranes. Given their exposure to diverse weather conditions and constant vehicular movement, water infiltration and subsequent damage are potential concerns. To combat this, waterproofing membranes act as a safeguard, effectively blocking water from seeping into the structure and causing deterioration. These membranes are engineered to withstand significant loads and resist the harmful effects of automotive fluids, making them an optimal choice for parking decks. By implementing waterproofing membranes, the lifespan of the parking deck can be prolonged, minimizing the necessity for expensive repairs and guaranteeing the safety and integrity of the structure.

- Q: Can a waterproofing membrane be used for planter boxes or green roofs?

- Yes, a waterproofing membrane can be used for planter boxes or green roofs. It helps to prevent water leakage and protect the underlying structure.

- Q: Can a waterproofing membrane be used for a hotel swimming pool area?

- Yes, a waterproofing membrane can be used for a hotel swimming pool area. A waterproofing membrane is a specially designed material that is applied to surfaces to prevent water penetration. It forms a protective barrier that prevents water from seeping into the underlying structure, protecting it from damage caused by water exposure. In the case of a hotel swimming pool area, a waterproofing membrane can be applied to the pool shell and surrounding areas to prevent water from leaking into the building or surrounding structures. This helps to maintain the integrity of the pool area and prevent any potential water damage. Additionally, a waterproofing membrane can also help to prevent the growth of mold and mildew, as it creates a moisture barrier. Therefore, using a waterproofing membrane for a hotel swimming pool area is a wise choice to ensure the longevity and durability of the pool and surrounding structures.

- Q: Can a waterproofing membrane be applied to curved surfaces?

- Yes, a waterproofing membrane can be applied to curved surfaces. There are various methods and products available that are specifically designed to adhere to and cover curved surfaces. These membranes are flexible and can be molded or stretched to fit the shape of the curved surface, ensuring a tight and secure seal. The application process may require additional care and attention to ensure proper adhesion and coverage, but it is certainly possible to waterproof curved surfaces effectively.

- Q: What is the difference between a self-adhesive and torch-applied waterproofing membrane?

- The main difference between a self-adhesive and torch-applied waterproofing membrane lies in the method used to adhere the membrane to the substrate. Self-adhesive waterproofing membranes have a pre-applied adhesive layer which allows for easy installation by simply removing the backing and sticking it onto the surface. On the other hand, torch-applied waterproofing membranes require the use of a propane torch to heat the underside of the membrane, melting the bitumen layer and allowing it to bond with the substrate. While both methods provide effective waterproofing, the choice between self-adhesive and torch-applied membranes depends on factors such as surface type, installation conditions, and personal preference.

Send your message to us

EPDM roof /pond/basement waterproof membrane manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords