Embossed Aluminum Sheets Houston - Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

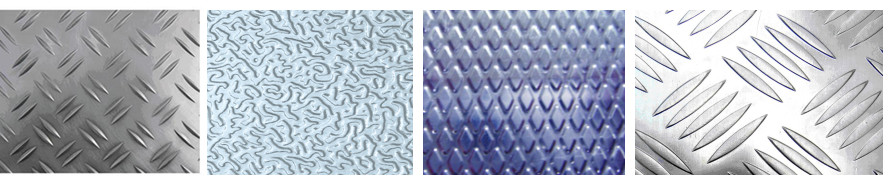

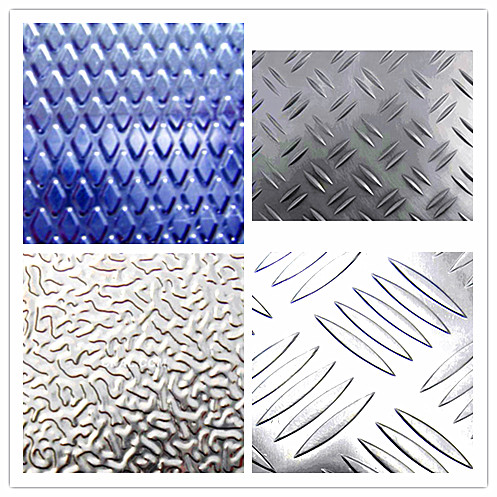

Aluminumtrade plate have great suctility, heat conductivity, anti-corrosion andmoisture resistance properties.

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754,5083,8011, etc

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm (Can be slitted)

Application:

Anti-slipery purpose in vehicles,packing and appliance, decorative purpose

Business Items

1. Payment: T/T or LC at sight

2. Delivery time: 20 Days

3. Packing:

(1) EPE:protect aluminum.

(2) Plastic sheet:water-proof

(3 )Carton:anti-shock.4 Steel bar:fix

4. Quality: Mill Finish, Totally free from defects like White Rust, Roll Marks, Edge damage , Camber,Dents,Holes,Break Lines, Scratch

Dimensions can be produced according to your specifications,if you need any further details,please be free to tell us,we assure you of our best servieces.

If you are interested in our products, please contact us.

- Q: Are 101 aluminum sheets suitable for decorative purposes?

- Yes, 101 aluminum sheets are suitable for decorative purposes. These sheets are made of high-quality aluminum alloy, which provides a sleek and polished appearance. They have excellent corrosion resistance and are easy to clean, making them ideal for use in decorative applications. Additionally, 101 aluminum sheets can be easily cut and shaped, allowing for creative designs and customization. Whether it's for interior or exterior decoration, these sheets can be used for various purposes such as wall cladding, signage, furniture accents, and more. With their durability and aesthetic appeal, 101 aluminum sheets are a great choice for adding a touch of elegance to any space.

- Q: What are the different forming methods for aluminum sheets?

- Aluminum sheets can be shaped using various forming methods. These methods encompass: 1. Roll Forming: By passing the aluminum sheets through a series of rollers, they gradually take on the desired form. Roll forming is commonly employed to produce elongated shapes like channels or rails. 2. Press Forming: This technique involves utilizing hydraulic or mechanical presses to exert force on the aluminum sheet, resulting in the desired shape. Press forming is often favored for creating intricate shapes with precise tolerances. 3. Stretch Forming: The aluminum sheet is clamped at its edges and then stretched over a die, causing it to conform to the die's shape. Stretch forming is frequently utilized to manufacture curved or contoured parts. 4. Deep Drawing: This method entails inserting an aluminum sheet blank into a die and using a punch to force the material into the die cavity, creating a hollow shape. Deep drawing is commonly employed for producing cylindrical or box-shaped parts. 5. Hydroforming: Hydraulic pressure is employed to shape the aluminum sheet against a die. Hydroforming is particularly advantageous for crafting complex shapes with smooth surfaces. 6. Incremental Sheet Forming: This technique involves a CNC machine moving a small tool over the aluminum sheet's surface, gradually shaping it by applying localized pressure. Incremental sheet forming is often employed for prototyping or small-scale production. These forming methods offer distinct advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and production volume.

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust. This is because aluminum naturally forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. Unlike iron or steel, which can rust when exposed to moisture and oxygen, aluminum does not require any additional coatings or treatments to protect it from rusting. This makes aluminum sheets a popular choice for a wide range of applications, including construction, automotive, and marine industries, where resistance to rust is essential.

- Q: It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- I have an aluminum double boiler.. that I only used for making pie pudding and yes, it got yucky. I found something and I cleaned it and i was so proud of myself but that was a while ago and it am racking my brain to remember. If I recall, I'll try to get back to you and let you know, but for now, I think it was the using CLR cleaner. Good luck. And if they say not to use it... I'd say it was time to update. Clean it... for display or sale to collectors.

- Q: The radius of an atom of aluminum is 143pm and there are 10^12 in a meter. The aluminum is a 3x3cm square. The density is 2.70 g/cm^3. I found the mass to be 0.03g. I found the volume to be 0.09cm^3

- Good quality standard aluminum foil such as Reynolds brand is 0.007 inches thick. If aluminum atoms are indeed 143 picometers in radius then the foil would be 2,486,713 atoms thick. Of course, the thickness is not controlled to a tolerance of one atom. (Cheaper brands are about 0.0060 to 0.0065 inches thick.) The ionic radius of aluminum is commonly accepted to be 72 pm, and as of 2008 a covalent radius of 121 pm. . .

- Q: How do you clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, start by rinsing them with water to remove any loose dirt or debris. Then, prepare a mixture of mild dish soap and warm water. Use a soft cloth or sponge to gently scrub the aluminum sheets with the soapy solution, paying attention to any stains or marks. Rinse thoroughly with clean water and dry the sheets using a clean towel or allow them to air dry. To maintain the shine and prevent oxidation, you can apply a thin layer of aluminum polish or a non-abrasive metal cleaner occasionally. Avoid using harsh chemicals or abrasive scrubbers that may cause scratches or damage to the surface.

- Q: What are the different machining options for aluminum sheets?

- There are several different machining options available for aluminum sheets, depending on the desired outcome and the specific requirements of the project. Some of the most common machining options for aluminum sheets include: 1. Cutting: Aluminum sheets can be cut using various methods such as shearing, sawing, or laser cutting. Shearing involves using a shearing machine to apply a high force to the sheet, resulting in a clean and straight cut. Sawing, on the other hand, utilizes a saw blade to cut through the aluminum sheet. Laser cutting uses a high-powered laser beam to melt or vaporize the aluminum, resulting in a precise and accurate cut. 2. Drilling: Drilling is a common machining option used to create holes in aluminum sheets. This process involves using a drill bit to remove material from the sheet, creating a hole with the desired diameter. Different drill bits can be used to achieve specific hole sizes and shapes. 3. Milling: Milling is a versatile machining option that can be used to create complex shapes and contours in aluminum sheets. This process involves using a rotating cutting tool to remove material from the sheet, resulting in a precise and accurate finish. Milling can be done using various types of milling machines, such as vertical milling machines or CNC milling machines, depending on the complexity of the project. 4. Turning: Turning is another machining option used for aluminum sheets, especially when creating cylindrical or conical shapes. This process involves rotating the aluminum sheet against a cutting tool, which removes material and shapes the sheet to the desired dimensions. Turning can be done on manual lathes or CNC turning machines, depending on the level of precision required. 5. Bending: Bending is a common machining option used to create curved or angled shapes in aluminum sheets. This process involves applying force to the sheet, causing it to deform and take on the desired shape. Bending can be done manually using tools like a brake press, or it can be done using hydraulic or CNC press brakes for more precise and consistent results. These are just a few of the different machining options available for aluminum sheets. The choice of machining method will depend on factors such as the desired outcome, the complexity of the project, and the resources available. It is important to select the most suitable machining option to achieve the desired results efficiently and effectively.

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Yes, aluminum sheets are suitable for manufacturing kitchen backsplashes. Aluminum is a durable and lightweight material that is resistant to rust and corrosion, making it ideal for use in kitchen environments. Additionally, aluminum sheets can be easily cut and shaped to fit various design preferences, providing a sleek and modern look to any kitchen backsplash.

- Q: How do aluminum sheets compare to steel sheets in terms of strength?

- Strength differs between aluminum sheets and steel sheets. Steel is generally stronger than aluminum due to its higher tensile strength, allowing it to withstand greater forces without breaking or deforming. Steel sheets find common use in construction, automotive manufacturing, and aerospace, where high strength and durability are necessary. Conversely, aluminum sheets strike a good balance between strength and weight. Although not as strong as steel, aluminum is significantly lighter, making it advantageous in applications prioritizing weight reduction, such as aircraft and vehicle manufacturing. Additionally, aluminum sheets exhibit excellent corrosion resistance, making them suitable for outdoor or marine environments. Ultimately, the choice between aluminum and steel sheets hinges on the specific requirements of the application, considering factors like strength, weight, durability, and corrosion resistance.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Indeed, aluminum sheet possesses the capacity to be effortlessly bent or molded into diverse forms. As a remarkably ductile metal, aluminum can be bent, shaped, or molded without any risk of cracking or fracturing. This characteristic renders it a perfect selection for a wide array of applications where adaptability and customization are essential. Multiple techniques, including the utilization of a brake press, roll forming, or specialized bending tools, can be employed to bend aluminum sheets. The degree of bendability may vary based on the thickness and grade of the aluminum sheet. Nevertheless, in general, aluminum is renowned for its exceptional malleability and aptitude to assume various configurations.

Send your message to us

Embossed Aluminum Sheets Houston - Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords