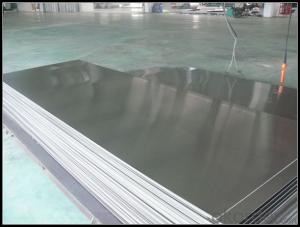

Polished or Embossed 1~8series Aluminum Sheets Houston TX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Alloy number: 1-8 series

Temper: all tempers

Thickness: 0.15-300mm

Width: <=2200mm< span="">

Length: <=12000mm< span="">

The above is our normal specification; others can be done according to the customer's request.

Export standard: covering with brown paper and plastic film then packed with steel band & wooden case/pallet. Or can according to the customer's request.

Our Services

CNBM can provide you:

1. CNBM is specialized in aluminum product.

2. CNBM would like to offer best service and help you company save costs.

3. All risk of orders is within Taimei account until you company has received products smoothly.

4. Upon receipt of your purchase order, production will be arranged immediately.

5. After-sales service time: CNBM does its best to serve customers the best that CNBM can.

FAQ

1. Process

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery

2. Main application

Embossed Aluminum Sheet widely used in curtain wall ,kitchen utensils, food and chemical products processing and storage equipment, transport of liquid products, tank, tank, to a variety of sheet metal processing, pressure vessels and piping, heat exchangers, rivets, welding, washing machines, cylinder and so on.

3. About Us

CNBM is a specialized manufacturer and exporter for 1*** 3*** 5*** 6**** 8*** series aluminum sheet, coil, foil and PS base plate. such as hot -rolled thick plate, aluminum circle/disc for cookware, aluminum drilling entry for PCB, aluminum tape for aluminum plastic tube, aluminum base plate for PS plate, aluminum bright finish tread plate, aluminum circles, aluminum checkered plate, PP cap materials and others. These products are generally applied to air-conditioner, washing machine, refrigerator, cosmetic package, printing, building decoration, aluminum ROPP cap, bus floor, and telecommunication cable etc. fields.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a highly conductive material, making it suitable for use in grounding systems. It is often used in various electrical applications due to its low resistance and excellent electrical conductivity. Aluminum sheet can effectively carry electrical current and safely dissipate it into the ground, ensuring the protection of electrical systems and preventing electrical hazards. Additionally, aluminum's lightweight and corrosion-resistant properties make it a preferred choice for grounding applications in various industries, including construction, automotive, and aerospace.

- Q: What are the different surface treatments available for aluminum sheet?

- There are several surface treatments available for aluminum sheet, including anodizing, powder coating, painting, and polishing. Anodizing provides a durable and corrosion-resistant finish, while powder coating offers a wide range of colors and enhanced durability. Painting allows for customization with various finishes and colors, while polishing provides a shiny and reflective surface. Each treatment option offers different aesthetic and functional benefits, depending on the specific requirements and desired outcome.

- Q: What kind of material is 2A12 aluminum sheet?

- Corrosion resistance is poor, but it can be effectively protected by pure aluminum coating. It is easy to crack when welding, but it can be welded or riveted by special process. Widely used in aircraft structures, rivets, truck hubs, propeller components, and many other structures.

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring.

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Is it feasible to recycle aluminum sheets and what factors contribute to its recyclability?

- <p>Yes, aluminum sheets can be recycled easily. Aluminum is one of the most recycled materials due to its lightweight, durability, and the energy efficiency of the recycling process. The recycling of aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it an environmentally friendly choice. Proper sorting and collection systems are crucial for efficient recycling, and the demand for recycled aluminum is high in various industries, further facilitating its recycling process.</p>

- Q: How does the purity of aluminum affect its properties as a sheet?

- The purity of aluminum greatly affects its properties as a sheet. Higher purity levels result in increased strength, improved corrosion resistance, and enhanced conductivity. Pure aluminum sheets are softer and more malleable, making them easier to form and shape. However, impurities can negatively impact these properties, reducing strength and increasing susceptibility to corrosion. Therefore, maintaining high purity levels is essential for achieving desired sheet properties and performance.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Indeed, aluminum sheets prove to be a fitting material for the production of aircraft wings. In the aerospace sector, aluminum is extensively utilized owing to its remarkable strength-to-weight ratio, ability to resist corrosion, and high thermal conductivity. These attributes render it an ideal option for fabricating aircraft components that are both lightweight and robust, such as wings. Aluminum sheets can be easily molded, fused, and processed, enabling the creation of intricate wing designs. Furthermore, the low density of aluminum aids in reducing the overall weight of the aircraft, thereby enhancing fuel efficiency and maneuverability. In summary, the utilization of aluminum sheets in the manufacture of aircraft wings is a prevalent and validated practice within the aviation industry.

- Q: Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed. Aluminum is a highly malleable and ductile metal, which means it can easily be shaped or bent without breaking. This characteristic makes it a popular choice for various applications, such as manufacturing automotive parts, aircraft structures, and household items. Aluminum sheets can be bent or formed using various techniques, such as press braking, roll bending, and stretch forming. These methods allow the aluminum sheets to be shaped into different angles or curves to meet specific design requirements.

- Q: Is it possible for an individual to install their own aluminum sheet roofing?

- <p>Yes, you can install your own aluminum sheets roof, but it requires some skills and knowledge. You'll need to measure and cut the sheets accurately, secure them properly, and ensure watertight installation. It's advisable to have experience in roofing or construction, or to follow detailed instructions and safety precautions. For complex roofs or if you're unsure, hiring a professional is recommended to avoid damage or injury.</p>

Send your message to us

Polished or Embossed 1~8series Aluminum Sheets Houston TX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords