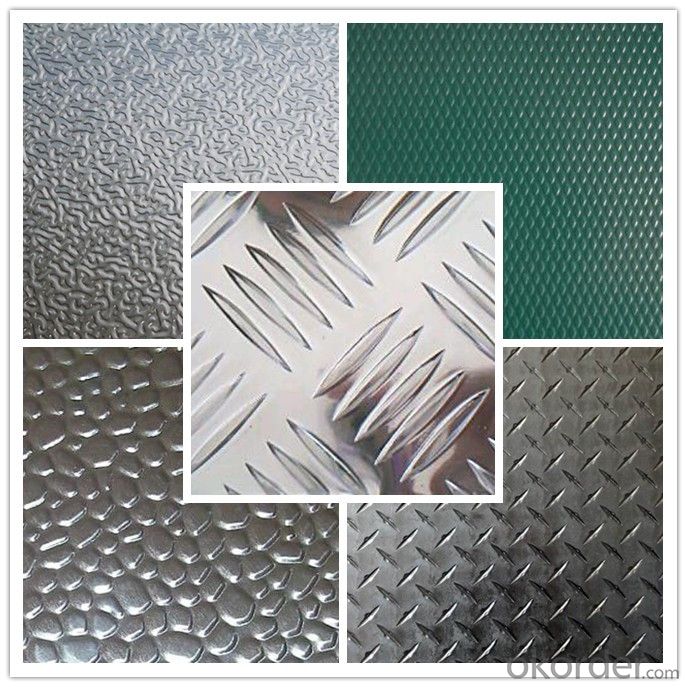

Powder Coated Embossed Aluminum Sheet Plate with Low Noise - 5 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Embossed Aluminum Sheet Plate With Low Noise - 5 Bar

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition of Embossed Aluminum Sheet Plate With Low Noise - 5 Bar

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make it an ideal material for manufacturing aircraft structures, such as fuselages, wings, and structural components. Additionally, aluminum can be easily machined and formed into complex shapes, allowing for the production of lightweight and aerodynamic structures. Furthermore, aluminum sheets can be easily joined using various techniques, including welding and riveting, ensuring the structural integrity of aerospace components. Overall, aluminum sheets are well-suited for aerospace applications and have been extensively utilized in the industry for many years.

- Q: What kind of paint would you like to paint on the aluminum plate?

- Try to brush the high quality magnetization paint, the aluminum plate brush can be brushed, will not move, also won't fall lightly.

- Q: As for graphite and aluminum sheet, which one has a better thermal conductivity?

- aluminum sheet

- Q: Are the aluminum sheets suitable for manufacturing traffic signs?

- Yes, aluminum sheets are highly suitable for manufacturing traffic signs. Aluminum is a durable, lightweight, and corrosion-resistant material, making it ideal for outdoor applications. It can withstand harsh weather conditions and remains visible for a long time. Additionally, aluminum is easy to work with, allowing for easy customization and installation of traffic signs.

- Q: Can the aluminum sheets be used for manufacturing kitchen countertops?

- Yes, aluminum sheets can be used for manufacturing kitchen countertops.

- Q: What are the different methods for joining aluminum sheets?

- Depending on the desired outcome and specific application, there are various methods available for joining aluminum sheets. The following are some commonly used techniques: 1. Welding: Different welding techniques, such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW), can be employed to weld aluminum sheets. TIG welding is often preferred for thin sheets as it produces a strong and precise joint. MIG welding, on the other hand, is suitable for thicker sheets and allows for faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be utilized to join aluminum sheets, providing a reliable and sturdy connection. This method allows for easy disassembly if necessary. Rivets are another commonly used mechanical fastening method, where the sheets are secured using a rivet gun that deforms the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often chosen for its ability to create a clean and seamless appearance, making it ideal for situations where aesthetics matter. Adhesive bonding also helps distribute stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process that involves deforming the aluminum sheets using a punch, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that utilizes a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own set of advantages and disadvantages. The choice of method depends on factors such as the desired strength, appearance, production rate, and specific requirements of the application.

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- The difference is as follows: 1, different layers: single aluminum plate is divided into two layers, the surface layer is aluminum skin, second layers of plastic, aluminum plate is divided into three layers: the surface layer and the third layer is an aluminum sheet, the middle is plastic, or aluminum plate than single aluminum plate a layer of aluminum skin; 2, the quality of different because: aluminum sheet aluminum plastic board less than a layer of aluminum skin, so the single aluminum plate than the aluminum plate quality will certainly be worse; 3, the price is different: single aluminum plate is cheaper than aluminum plate, aluminum plate positioning for low-grade, aluminum-plastic plate according to the quality and thickness of plastic and aluminum skin into the middle different grades, but certainly more than the single aluminum plate and expensive; 4, the construction effect is certainly not the same: a plastic plate can be slotted, bending turning construction construction, suitable for a variety of occasions, but not the single aluminum plate slot, bending, and because the bottom is plastic, such as plastic bonding effect Board.

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- cracked where? i could suggest the wonder rods, such as dura-fix. i've used them on some aluminum repairs in the past. when the thickness of the materials is uniform, its a good easy to use product. when the thickness changes, its useless. i wouldnt think of using it on a motor repair though. melting temp is a bit low, much closer to combustion temps then alum's melting temp. the truly best way to fix anything alum is with a TIG welder in the hands of somebody who knows how to use it. but, any good welder will probably look at you like you are nuts when you bring a motor in to be welded. depending on exactly what you have, the entire powerblock, which is the motor part, might be avaible for purchase to replace your old one with. it may be priced at under a $1,000. you would end up with a brand new motor. for outboards, when teh drive is in good condition, this can be a great way to get a brand new outboard performance at a far cheaper price.

- Q: Can the aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding.

- Q: What are the different surface treatments available for aluminum sheets?

- Some of the different surface treatments available for aluminum sheets include anodizing, painting, powder coating, and polishing. Anodizing provides a durable and corrosion-resistant finish by creating an oxide layer on the surface of the aluminum. Painting involves applying a coat of paint to the sheet, which can provide both protection and aesthetic appeal. Powder coating is a process where a dry powder is applied to the aluminum and then heated, creating a durable and vibrant finish. Polishing involves buffing the surface of the aluminum to create a smooth and reflective finish.

Send your message to us

Powder Coated Embossed Aluminum Sheet Plate with Low Noise - 5 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords