Aluminum Sheet Embossed Aluminum Sheet Coated Aluminum Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

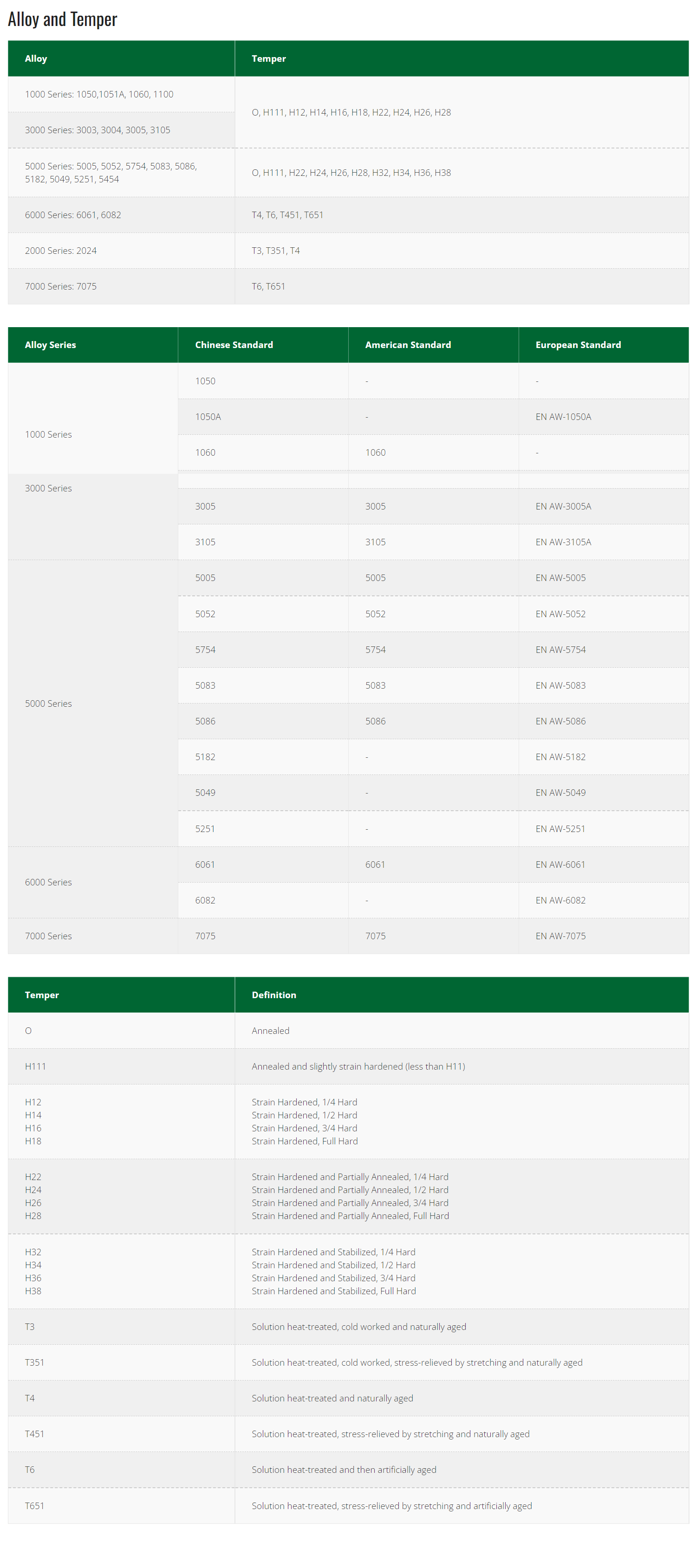

Specification

Aluminium sheets come in a wide range of grades and thicknesses, offering solutions for different needs. Whether in standard sizes or custom

specifications, aluminium sheets are produced with strict manufacturing processes to ensure stable quality and reliable performance.

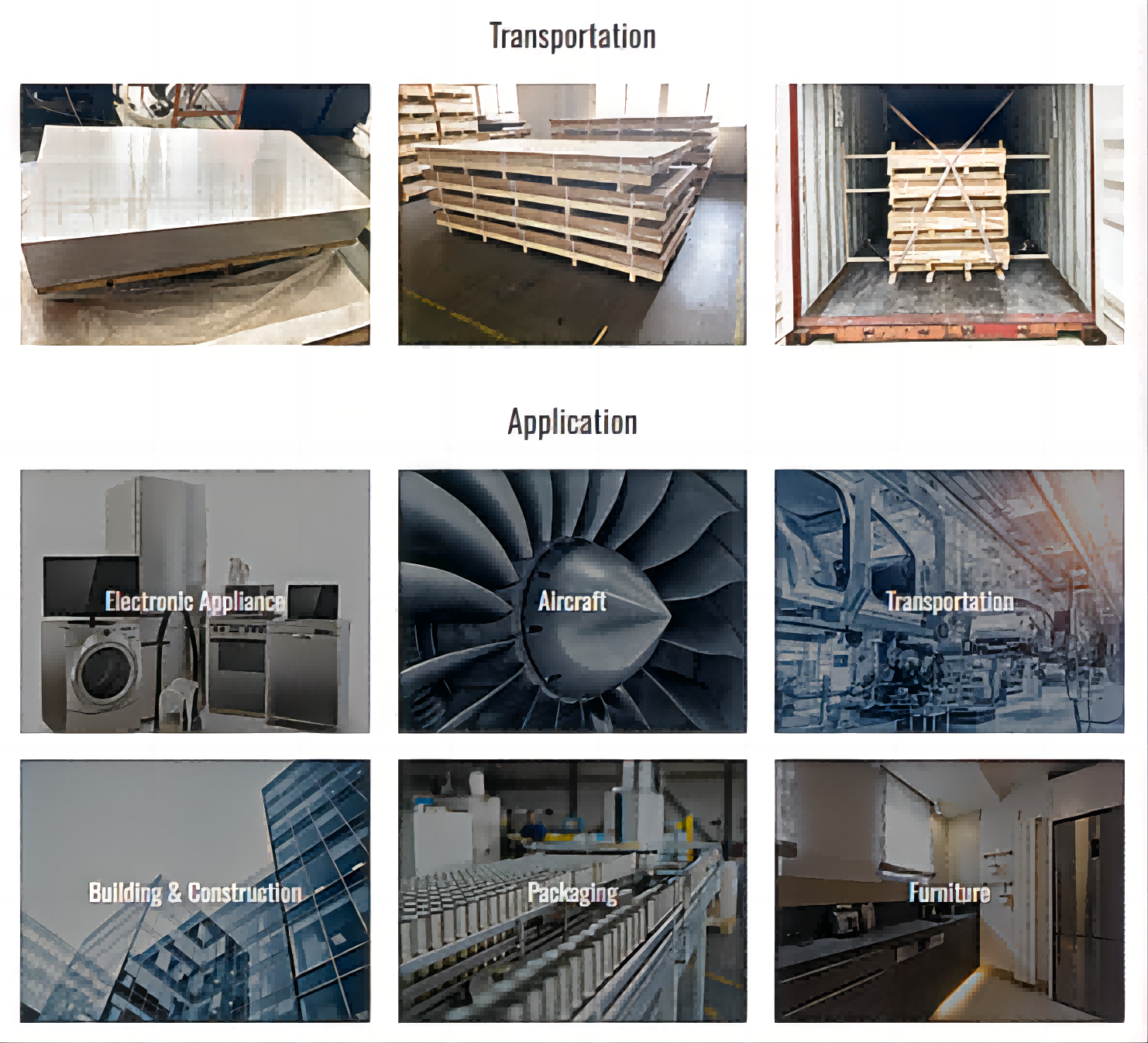

With its outstanding properties and versatility, aluminium sheet is a preferred material choice across numerous sectors.

Advantages:

Lightweight: Aluminium sheets are significantly lighter than many other metals, making them ideal for applications where weight reduction is crucial.

Corrosion Resistance: Aluminium naturally forms a protective oxide layer, which enhances its resistance to corrosion, particularly in harsh environments.

High Strength-to-Weight Ratio: This property allows for the creation of strong yet lightweight components, beneficial in industries like aerospace and automotive.

Malleability: Aluminium sheets can be easily formed into complex shapes, allowing for diverse design possibilities.

Thermal Conductivity: Aluminium is an excellent conductor of heat, making it suitable for applications like heat sinks and thermal management systems.

Recyclability: Aluminium is fully recyclable, making it an environmentally friendly material choice. Recycled aluminium retains its original properties, supporting sustainable practices.

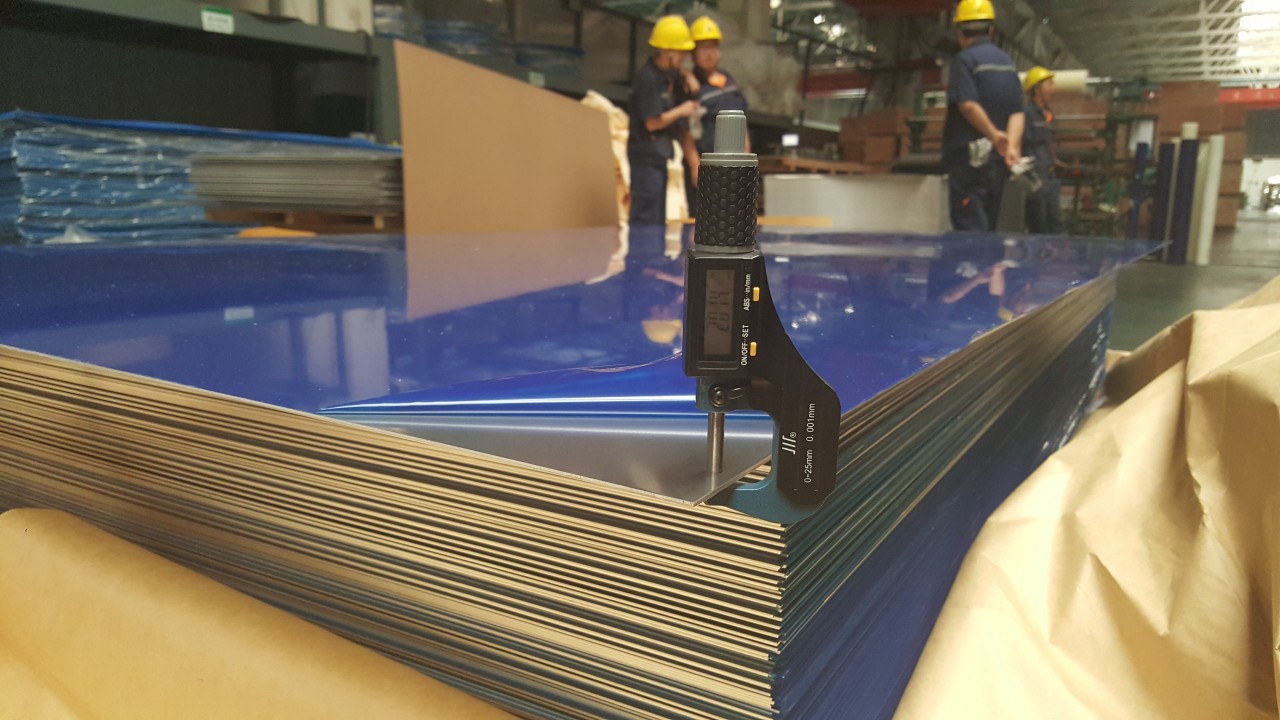

Images:

Maintenance and Care:

Cleaning: Regular cleaning with mild detergent and water can maintain the appearance and prevent build-up of contaminants.

Protection: For enhanced durability, consider applying protective coatings such as anodizing or painting.

Inspection: Periodic inspection for signs of wear, corrosion, or damage ensures long-term performance and safety.

Handling: Proper handling during transport and installation prevents dents, scratches, and other damage.

FAQ:

1. what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2.What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3.Can we supply samples?

Yes, we can!

4.What can you do if you have other quastions?

You can contact us freely at any time!

- Q: How do aluminum sheets perform in terms of fire resistance?

- Aluminum sheets possess outstanding fire resistance characteristics. This material, aluminum, is non-combustible, meaning it does not burn or contribute to the propagation of fire. In fact, aluminum has a remarkably high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), rendering it highly resistant to heat. When subjected to fire, aluminum generates a thin layer of oxide on its surface, creating a protective barrier that hinders further oxidation. This oxide layer is highly stable and effectively prevents the material from igniting or emitting flammable gases. Moreover, aluminum sheets exhibit low thermal conductivity, which reduces the ease with which they transfer heat compared to other metals. This property further enhances their fire resistance. These fire-resistant attributes position aluminum sheets as a preferred choice in a wide range of applications where fire safety is a primary concern, including building construction, aerospace industry, automotive manufacturing, and electrical enclosures. Aluminum sheets are commonly utilized in exterior cladding, roofing, and insulation systems, providing an additional layer of safeguard against fire hazards. It is essential to acknowledge that while aluminum sheets themselves possess high fire resistance, the overall fire performance of a structure or system relies on factors such as design, installation, and the use of other materials in conjunction with aluminum sheets. Therefore, it is vital to adhere to appropriate fire safety regulations and guidelines to ensure optimal fire resistance in any given application.

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- in case you have coverage or can cope with to pay for to - flow see an Ear nostril Throat wellbeing care professional (additionally spoke of as otolaryngologist or ENT for short) it incredibly is the main secure and smartest element to do. maximum probable he will prescribe an ear flush for you that works o.k.. additionally, listening to in triplicate may well be a symptom of nerve inflammtion or different ailment which will properly be examined for quite truthfully by potential of a doctor. Odds are this is not something, yet extra effective risk-free than sorry.

- Q: Is aluminum a metal or a non-metal?

- Aluminum is a metal.

- Q: Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

- Q: What is the typical shear strength of aluminum sheets?

- The shear strength of aluminum sheets can vary depending on several factors, including the alloy, temper, thickness, and manufacturing process. Typically, common aluminum alloys have a shear strength ranging from 207 to 310 megapascals (MPa) or 30,000 to 45,000 pounds per square inch (psi). It is crucial to understand that these values serve as general guidelines, and specific applications and conditions may result in variations. When dealing with critical applications, it is advisable to refer to the material specifications or consult professionals to accurately determine the shear strength requirements for the specific aluminum sheet in use.

- Q: What specific requirements or considerations are necessary when using aluminum sheets in marine environments?

- <p>In marine environments, aluminum sheets must meet specific requirements to ensure durability and resistance to corrosion. These include using high-grade aluminum alloys, such as 5083 or 5086, known for their excellent resistance to saltwater corrosion. Protective coatings like anodizing or applying marine-grade paints can further enhance corrosion resistance. Additionally, the aluminum sheets should be designed to withstand the harsh conditions of marine environments, including high humidity, UV radiation, and mechanical stress. Regular maintenance and inspection are also crucial to prevent corrosion and ensure the longevity of aluminum structures in marine settings.</p>

- Q: Are aluminum sheets suitable for reflective signage?

- Yes, aluminum sheets are highly suitable for reflective signage due to their excellent reflective properties. The smooth surface of aluminum ensures high visibility and increased reflectivity, making it an ideal material for creating reflective signage that is easily visible, even in low light conditions.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets have a protective oxide layer that provides increased corrosion resistance, durability, and a decorative finish. They are lightweight, non-toxic, and offer excellent heat and electrical conductivity. Additionally, anodized aluminum sheets are easy to clean, resistant to fading and scratching, and can be dyed in various colors for aesthetic purposes.

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- Unless you are an all star pro, a steel bike will suit you fine. Thing is, the difference in weight is so small that unless you are racing people in multi-national competitions, it's just a lot of extra money you could put into buying a REALLY nice steel frame. Don't let ads fool you, steel are just as good as aluminum.

- Q: Can aluminum sheets be used for electronic devices?

- Indeed, electronic devices can utilize aluminum sheets. The electronics industry extensively employs aluminum owing to its commendable conductivity, lightweight structure, and remarkable resilience. It is frequently employed in diverse capacities, including enclosures for electronic elements, heat dissipation systems, and electrical connectors. Aluminum sheets can be effortlessly shaped into various dimensions and configurations, rendering them adaptable for a broad array of electronic devices. Moreover, aluminum emerges as a cost-efficient material, fostering its allure to electronics manufacturers.

Send your message to us

Aluminum Sheet Embossed Aluminum Sheet Coated Aluminum Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords