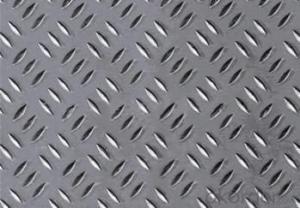

Aluminum Painted Embossed Diamond Aluminum Sheet - Diamond Embossed Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

Electrodes in the aluminum foil, aluminum foil wool, the curtain with aluminum belt, 3105, 1235, 1050, 1145, 1200, 8011 o, H22, H24, H26, H180.20 ~ 0.80 mm, width 800 ~ 1900

Non-slip aluminum sheet 7. All kinds of decorative pattern, five reinforcement, the pointer shape and decorative pattern, in addition, produce 3003 orange peel pattern aluminum coil.

Goods of Description:

1. Roll casting slab billet 1060105 0107 0110 0300 3310, 5, 3 A21, LF21, 5052801 1, etc.

2. Various USES aluminum plate, various USES aluminium strip, processing customized according to user requirements.

3. The cable foil, cable aluminum belt, cable coated with aluminum foil, 8011 o0. 12 ~ 0.20 mm wide, 50 ~ 1300106 0 O0.5 ~ 2.0 mm wide, 50 ~ 1300.

4. Lu: su composite work aluminum strip, 8011 o0. 16-10-1200 - mm * 0.3 mm * l.

5. Aluminium and aluminium alloy curtain wall construction, decoration, 1070, 1070, 1050, 3003, 3 a21h16, H14, H26, H181.5 ~ 4.0 mm wide, 1000 ~ 1000 long and 1000 ~ 6000.

Application:

suitable for wastewater treatment, water, power plant in other industries outside, checkered plate is used for mechanical antiskid and interior decoration, prevent slippery, wharf, diaoyutai state guesthouse, workshop, at the bottom of the car, cement floor, the door of the hotel, etc.

- Q: Can 101 aluminum sheets be used in the production of musical instruments?

- Yes, 101 aluminum sheets can be used in the production of musical instruments. They offer good conductivity and durability, making them suitable for various components like instrument bodies, panels, or parts that require lightweight construction.

- Q: Do 101 aluminum sheets have any specific insulation properties?

- 101 aluminum sheets do not possess any distinct insulation properties, as aluminum is an efficient conductor of both heat and electricity, failing to offer protection against temperature extremes. Nevertheless, these sheets can serve as reflective surfaces, effectively bouncing back heat or light. To achieve insulation, it is necessary to incorporate supplementary materials like foam or fiberglass in conjunction with the aluminum sheets.

- Q: What are the rules or laws concerning the application of flame-retardant coatings on aluminum sheets?

- <p>Yes, there are regulations regarding the use of flame-retardant coatings on aluminum sheets. These regulations vary by country and application, but they generally aim to ensure safety and compliance with fire safety standards. In the United States, for example, the National Fire Protection Association (NFPA) provides guidelines, and building codes like the International Building Code (IBC) may specify requirements for flame retardancy. The European Union has its own set of standards, such as EN 13501, which classifies the reaction to fire performance of construction products. Compliance with these regulations is crucial to ensure that the aluminum sheets and their coatings meet the necessary safety standards and to avoid legal penalties.</p>

- Q: Are aluminum sheets suitable for electrical bus bars?

- Certain applications may find aluminum sheets suitable for use in electrical bus bars. Aluminum possesses several properties that make it a viable choice for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in situations where weight reduction is crucial. Furthermore, aluminum exhibits good electrical conductivity, although it falls short of copper in terms of conductivity. Nevertheless, aluminum bus bars can still handle high electrical currents and are commonly employed in power distribution systems. However, one drawback of aluminum bus bars is their higher resistance compared to copper bus bars. Consequently, they have a tendency to generate more heat, particularly under heavy current loads. To address this issue, aluminum bus bars are often designed with larger cross-sectional areas to minimize resistance and dissipate heat more effectively. Another challenge associated with aluminum bus bars is their vulnerability to oxidation and corrosion. This concern can be tackled by applying protective coatings or utilizing alloys that offer superior corrosion resistance. Additionally, it is crucial to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In conclusion, aluminum sheets can serve as suitable materials for electrical bus bars, particularly in scenarios where weight reduction is a priority. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: Can aluminum sheets be recycled indefinitely?

- Absolutely! Aluminum sheets have the remarkable ability to be recycled endlessly. This exceptional material, known for its sustainability and recyclability, undergoes a transformative process when recycled. By melting down aluminum sheets and shaping them into fresh ones, their quality and properties remain intact, unfaltering. This incredible repetition of recycling allows aluminum to secure its position as one of the most eco-friendly materials available. Not only does recycling aluminum sheets aid in the preservation of natural resources, but it also plays a crucial role in energy conservation and the mitigation of greenhouse gas emissions.

- Q: Do these frames rust? For example here is a link. But I am genuinely curious because in swimming pools, the hand rails going into the swimming pool have the same finish as this bike frame and they have white corrosion marks. Thank you in advanced

- Pool handrails are more likely to be made of fairly high grade stainless steel than aluminium, so a different chemistry. And to be picky, rust is a word usually used for steel and iron only. So, while aluminium might not rust, it can certainly corrode, under the right circumstances. People using trainers have reported issues with their sweat doing damage to their bikes for instance.

- Q: Characteristics of anodized aluminium plate

- (3) strong sense: the metal surface of aluminum anodic treatment of high hardness, as gem, scratch resistance, surface is not covered with paint, keep aluminum metal color, highlight the modern sense of metal, improve product quality and added value.(4) high fire resistance: pure metal products, the surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gases, fire protection and environmental protection requirements.

- Q: how to make aluminum products bright? How to polish or clean the products punch formed by 0.3mm aluminum sheet?

- you can try to grind it with magnetic grinder.

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets are known for their excellent creep resistance. Creep is the tendency of a material to slowly deform under a constant load over time. Compared to other metals, such as steel, aluminum has a relatively low creep rate, meaning it deforms at a slower rate under the same load and temperature conditions. This makes aluminum sheets suitable for applications requiring dimensional stability and resistance to long-term deformation. Additionally, aluminum's low creep resistance allows it to withstand high temperatures without significant deformation, making it suitable for use in various industries, including aerospace, automotive, and construction. However, it is important to note that the creep resistance of aluminum sheets can vary depending on the alloy used, heat treatment, and other factors, so it is essential to choose the appropriate aluminum alloy and design for specific applications to optimize creep resistance.

Send your message to us

Aluminum Painted Embossed Diamond Aluminum Sheet - Diamond Embossed Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords