Outdoor Aluminum Roof Sheets - Embossed Aluminum Sheet for Roofing Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Sheet Embossed for Roofing Making Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Sheet Embossed for Roofing Making:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

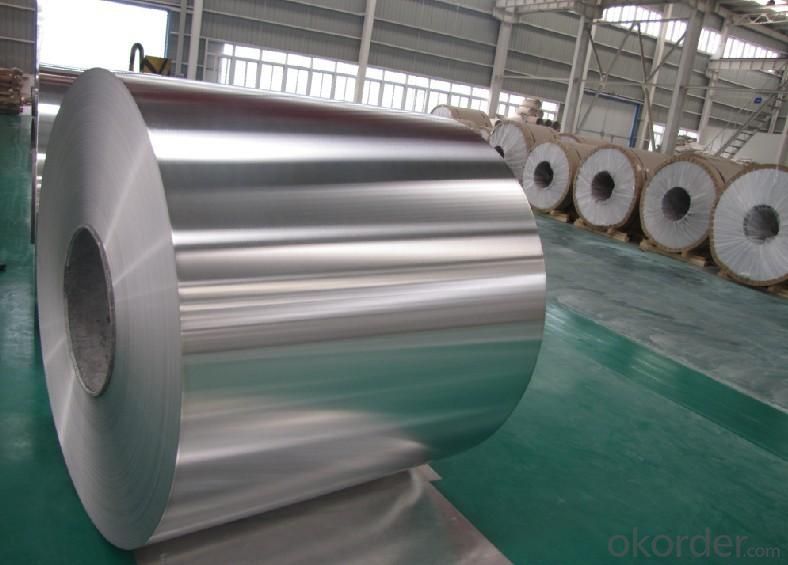

Images of the Aluminium Sheet Embossed for Roofing Making:

Aluminium Sheet Embossed for Roofing Making Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can 101 aluminum sheets be embossed or textured?

- Yes, 101 aluminum sheets can be embossed or textured.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Aluminum sheets are indeed a fitting choice for HVAC systems. The popularity of aluminum in HVAC systems stems from its numerous advantageous properties. To begin, aluminum is both lightweight and robust, making it effortless to handle and install in HVAC systems. Its low density also enables cost-effective transportation and reduces the overall weight of the HVAC units. Furthermore, aluminum possesses exceptional resistance to corrosion. Given that HVAC systems often encounter moisture and condensation, particularly in air conditioning units, aluminum's corrosion resistance ensures its durability and longevity in such environments. Moreover, aluminum sheets exhibit commendable thermal conductivity, facilitating efficient heat transfer throughout the HVAC system. This property holds particular significance in heating and cooling applications, as it aids in effectively distributing the desired temperature. In addition, aluminum is a non-toxic material, rendering it safe for use in HVAC systems that circulate air within buildings. It does not emit any harmful particles or gases, thereby ensuring the quality of indoor air. Lastly, aluminum is highly recyclable, contributing to its environmental friendliness. The ability to recycle aluminum sheets reduces the carbon footprint associated with HVAC systems and aligns with sustainability objectives. Taking all these advantages into account, aluminum sheets undeniably prove suitable for use in HVAC systems. They offer an optimal combination of strength, corrosion resistance, thermal conductivity, safety, and environmental friendliness.

- Q: What is the thermal conductivity of aluminum sheets?

- The thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin.

- Q: How do you prevent fingerprints on aluminum sheets?

- There are several strategies you can use to prevent fingerprints on aluminum sheets: 1. Opt for gloves: To avoid leaving fingerprints on aluminum sheets, a simple solution is to wear gloves while handling them. This creates a barrier between your hands and the surface, preventing any marks or smudges. 2. Thoroughly clean the surface: Before touching aluminum sheets, ensure that the surface is clean. Use a suitable cleaning agent or mild detergent to remove any dirt or oils. Dry the sheets completely with a lint-free cloth to minimize the chances of fingerprints sticking to the surface. 3. Apply a protective coating: Prevent fingerprints by applying a protective coating on the aluminum sheets. Clear lacquer or a clear protective film designed for this purpose are viable options. These coatings create a barrier that reduces the visibility of fingerprints and makes them easier to clean off. 4. Handle with care: Minimize direct contact with aluminum sheets to reduce the likelihood of fingerprints. Fingerprints are more likely to occur when pressure is applied or when the surface is repeatedly touched. Whenever possible, use tools or gloves to manipulate the sheets instead. 5. Proper storage: Ensure that aluminum sheets are stored in a clean and dust-free environment, away from potential contaminants. Consider using protective sleeves or covers to shield the sheets from fingerprints and other marks. By implementing these preventive measures, you can significantly decrease the occurrence of fingerprints on aluminum sheets, maintaining their cleanliness and visual appeal.

- Q: How are the aluminum plates cut?

- A little thick with shears or plasma cutting machine, cutting machine words cut out if more smooth, no burr, but the pattern is simple, can be arbitrary cutting plasma cutting machine, but cutting burrs, rough.

- Q: Can the aluminum sheets be painted or coated with a different color?

- Indeed, it is possible to paint or coat aluminum sheets with a different color. Aluminum, being a flexible material, lends itself well to the application of paint or coating in order to achieve the desired color or finish. This can be accomplished using a range of techniques, including powder coating, anodizing, or the use of liquid paint. These methods serve to both protect the aluminum sheet's surface and alter its color or appearance. The selection of the specific paint or coating will hinge upon the particular requirements and desired outcome. On the whole, the practice of painting or coating aluminum sheets is commonplace, granting opportunities for customization and aesthetic enhancement.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can be an alternative to wood in certain applications. Aluminum sheets have several advantages over wood, including being lightweight, durable, and resistant to corrosion and fire. They can be used in various industries such as construction, automotive, aerospace, and marine, where wood may not be suitable due to its limitations. However, the selection of material depends on the specific requirements of the application and the desired properties needed.

- Q: What are the different types of protective films available for aluminum sheets?

- There exists a variety of protective films for aluminum sheets, each offering distinct features and advantages. Some commonly used types include: 1. Polyethylene (PE) film: PE film is a favored option for safeguarding aluminum sheets due to its versatility and cost-effectiveness. It serves as a temporary shield against scratches, dust, dirt, and moisture during storage, transportation, and fabrication processes. PE film can be effortlessly applied and removed without leaving residue or causing damage to the aluminum sheet's surface. 2. Polyvinyl Chloride (PVC) film: PVC film is another popular protective film for aluminum sheets. It provides excellent protection against scratches, abrasions, and UV rays. Known for its durability, PVC film is suitable for long-term applications. It is available in different thicknesses and can be customized to meet specific requirements. 3. Polyolefin film: Polyolefin film is a type of shrink film that ensures comprehensive protection for aluminum sheets. It exhibits high resistance against punctures, tears, and moisture. By heat-shrinking onto the aluminum surface, polyolefin film creates a secure seal, preventing any damage during handling, storage, or transit. 4. Polyester film: Polyester film is a high-performance protective film that offers exceptional resistance against chemicals, solvents, and extreme temperatures. It serves as an excellent barrier against moisture, preventing corrosion and oxidation of the aluminum sheet. Polyester film is commonly utilized in demanding applications where maximum protection is required. 5. Adhesive-backed film: Adhesive-backed films are self-adhesive protective films that can be easily applied and firmly bonded to aluminum sheets. They provide a temporary protective layer against scratches, stains, and other surface damages. Available with different adhesive strengths, adhesive-backed films can be removed effortlessly without leaving residue or causing harm to the aluminum surface. It is crucial to choose the appropriate type of protective film based on the specific requirements and conditions in which the aluminum sheets will be utilized.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces.

Send your message to us

Outdoor Aluminum Roof Sheets - Embossed Aluminum Sheet for Roofing Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords