Drill Bit For Aluminum Plate

Drill Bit For Aluminum Plate Related Searches

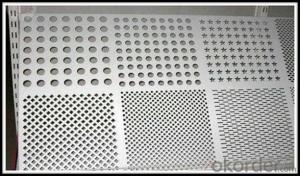

Drill Aluminum Plate Drilling Aluminum Plate Drilling Through Aluminum Plate Drilled Aluminum Plate Router Bits For Aluminum Plate Drill Bits For Stainless Steel Pre Drilled Aluminum Plate Hole Saw For Aluminum Plate Aluminum Dimple Plate Aluminum Sill Plate Buy Aluminum Plate Stainless Steel Drill Bit Drill Bit Stainless Steel Aluminum Grill Plate Aluminum Butt Plate Aluminum Dimond Plate Forming Aluminum Plate Aluminum Diffuser Plate Aluminum Profile Plate Aluminum Diamond Plate Trim Aluminum Plate For Sale Aluminum Round Plate Bow Plate For Aluminum Boat Buy Aluminum Diamond Plate Best Way To Cut Aluminum Plate Aluminum Deck Plate Aluminum Metal Plate Decorative Aluminum Plate Aluminum Build Plate Aluminum Motor PlateDrill Bit For Aluminum Plate Supplier & Manufacturer from China

Drill Bit For Aluminum Plate is a specialized tool designed for drilling into aluminum plates with precision and efficiency. These drill bits are engineered to minimize the risk of damaging the aluminum material during the drilling process, ensuring clean and accurate holes. They are made from high-quality materials to withstand the demands of drilling into aluminum, which can be a challenging task due to its softness and tendency to tear or deform.The drill bits for aluminum plates are widely used in various industries, including construction, automotive, aerospace, and electronics, where aluminum components are commonly utilized. These applications often require the creation of precise holes for fasteners, assembly, or other purposes. The drill bits are designed to handle the unique challenges posed by aluminum, such as its softness and the need for a smooth, clean hole without burrs or deformation. This makes them an essential tool for any professional or DIY enthusiast working with aluminum materials.

Okorder.com is a reputable wholesale supplier of drill bits for aluminum plates, offering a large inventory to meet the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the drill bits for aluminum plates they provide are of the highest standard, suitable for a wide range of applications. By partnering with Okorder.com, customers can access a reliable source for these essential tools, ensuring that their projects are completed with the precision and efficiency that aluminum drilling demands.

Hot Products