Electro Galvanized Iron Wire Low Carbon Steel Factory Directly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electro Galvanized Iron Wire Descrildn:

Electro galvanized iron wire is also known as electric galvanized iron wire or galvanized steel wire. We produces electric galvanized wire at diameter ranging from 0.14mm to 5.0mm, which can be supplied in the

form of coils, spools, U type wire or straightened and cut into tie wire. Electric Galvanized Iron Wire we produce usually goes through standard processes under careful control from steel rod coil, wire drawing,

annealing, rust removing, acid washing, boiling, drying, zinc feeding to wire coiling

Wire Diameter of Electro Galvanized Wire: 0.14mm - 5.0mm.

Zinc coating for Electro Galvanized Wire: about 8gram to 12gram.

Production Process of Electro Galvanized Wire:

Steel rod coil -- Wire Drawing -- Wire Annealing--Rust Removing-- Acid Washing-- Boiling-- Drying-- Zinc Feeding-- Wire Coiling.

It is also known as electric galvanized iron wire or galvanized steel wire. We produces electric galvanized wire at diameter ranging from 0.14mm to 5.0mm, which can be supplied in the form of coils, spools, U type

wire or straightened and cut into tie wire.Electric Galvanized Iron Wire we produce usually goes through standard processes under careful control from steel rod coil, wire drawing, annealing, rust removing, acid washing, boiling, drying, zinc feeding to wire coiling.

2.Main Features of Electro Galvanized Iron Wire:

• Antirust

• Shiny silvery color

• High strength

• Durable

• Good corrosion prevention

• Good visual effect

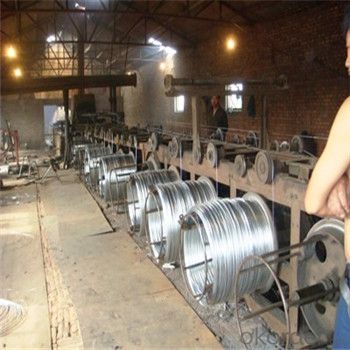

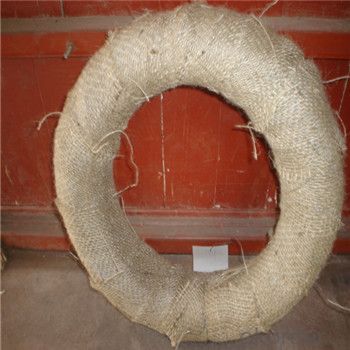

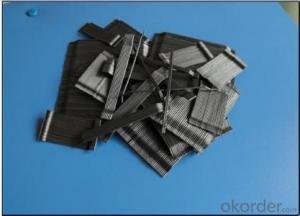

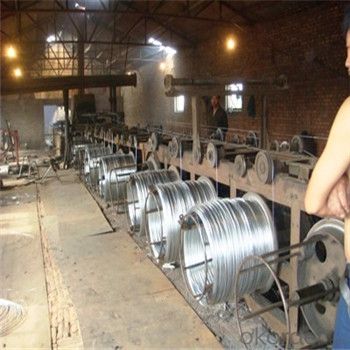

3. Electro Galvanized Iron Wire Images

4. Electro Galvanized Iron Wire Specification

| Galvanized wire | |||

| wire gauge size | SWG(mm) | BWG(mm) | metric(mm) |

| 8 | 4.06 | 4.19 | 4.00 |

| 9 | 3.66 | 3.76 | - |

| 10 | 3.25 | 3.40 | 3.50 |

| 11 | 2.95 | 3.05 | 3.00 |

| 12 | 2.64 | 2.77 | 2.80 |

| 13 | 2.34 | 2.41 | 2.50 |

| 14 | 2.03 | 2.11 | - |

| 15 | 1.83 | 1.83 | 1.80 |

| 16 | 1.63 | 1.65 | 1.65 |

| 17 | 1.42 | 1.47 | 1.40 |

| 18 | 1.22 | 1.25 | 1.20 |

| 19 | 1.02 | 1.07 | 1.00 |

| 20 | 0.91 | 0.89 | 0.90 |

| 21 | 0.81 | 0.813 | 0.80 |

| 22 | 0.71 | 0.711 | 0.70 |

5.FAQ

Q: What’s your advantages of our products?

A: 1)Our factory is close to the source of raw material

2)We’re near to the xingang, tianjin international seaport, so inland charge is lower.

3)Many eco-friendly equipment used in our workshop,

which save energy and raise the production efficiency.

So more competitive price of our products will be quoted for your evaluation.

Q:How do you ship the finished galvanized iron wire?

A:Usually by sea.

Q:What information should I provide,if I want a lowest quotation?

A:The specification of galvanized iron wire .such as material, quantity, wire gauge and coating thickness .

- Q: Wiring

- when connecting a wire dryer outlet to 10/2 with ground romex, where does the white/black and ground connect to on the outlet?

- Q: What is the use of Fence baebed wire?

- Cattle.etc...would push on the fence to eat the taller grass on the other side, The barbs change their mind...Also hog wire gives and stretches, barb wire doesn't. A cow would eventually ruin, and walk through, a hog wire fence that didn't have barb wire at the top and bottom edges.

- Q: Car audio wiring diagram

- If you cannot get a wiring diagram for your stereo or car. It's still pretty simple to install a stereo. You basically just gotta color code all the wires. Red sometimes orange is power wire, black is ground, blue is remote the rest are speaker wires. Look for wires that are identical such as light blue light blue with a white stripe, gray dark gray with a white stripe etc.....

- Q: ok so the passenger side back floorboard was getting wet and i believe the water to have corroded the wiring to my radio i've taken care of the water problem and know how to reconfigure the wiring but do i need to be worried about the security system while tinkering with the wiring see as how sensitive the security in these cars are i figured id check and see what you guys have to say about this pls also give resources as to how you know

- If you are going to replace wire by wire , you can do that first unplug the battery and be very care full with orange and pink wires, try to solder the new wires the factory amplifier is in the trunk left side good luck new wiring is $700 from the dealer and the only place to buy it new good luck

- Q: im installing a JVC raido in my 1990 nissan maxima and cant figure out how to properly conect the wires

- the radio comes with a wiring harness the easiest way to do it would be go to a pepboys,bestbuy, or autozone and get a radio wiring harness for 1990 maxima. this way all u have to do is splice the colored wires that match the same colored wires from the radio harness. once that`s done all u have to do it plug in back of radio and the car harness. the car harness will run u bought 18.00 but its worth it to do the job right

- Q: i need thin insulated wire like this.

- it is called enameled magnet wire. try an electronics supply house or a motor and transformer electrical supply house. you can also purchase it online. you could also just take apart an old electric fan or door bell and unwind the magnetic wire. ~the other answerers don't understand wire, enameled magnet wire has a fine enamel insulation that needs to be sanded off in order to make a connection, as the enamel electrically insulates it to prevent an obvious short, but allows the inductive fields to easily pass through. it is used in all motors and most xfmr's.

- Q: How do they differ from residential wiring?

- Commercial and industrial wiring make extensive use of conduit, cable trays/ This entails explosion-proof or flame-proof fittings, along with the seals and other conduit fittings. Residential wiring, in most cases make extensive use of romex cables without any conduit. Other than these major and a few minor differences, the wiring is actually the same. This is the installation of cables/wires from the circuit breakers to the users. TexMav

- Q: How can you make the fabric with silk fabric wrinkle free after washing?

- Hello, in order to prevent wrinkles after washing clothes, you should add the final rinse, softening agent, softening agent loss supplement when washing, in order to maintain the soft feeling, reduce wrinkles.

- Q: I just bought an aftermarket cd player for my Grand Cherokee and I would rather not have to cut and strip wires so I want to get an wiring harness adapter. My question is, can I just get any wiring harness adapter or do I need the direct connection adapter that is specifically made for Chrysler to Kenwood?

- You just get the jeep wiring adapter and then solder or use crimp caps/butt-connectors to connect the wires to the aftermarket harness that comes with the aftermarket headunit. Also, depending on what year Jeep you have you may need an antenna adapter. AND I believe on the Jeeps (like the chryslers) there is not a usable ground wire in the factory wiring harness which means you will need to ground the aftermarket ground wire to the chassis via an existing bolt or drilling. Or, if the stock radio has one of these metal-mesh things affixed to the back, you can use that thing as well. But when you match up the Jeep harness you buy to the factory harness and you will be able to tell if there is ground wire in factory harness.

- Q: Has anyone ever used welding wire in their car audio setup?Is it more flexible or less than other car power wire? Is this a big problem?Is it a good or bad jacket?Would you use it again?I am looking at buying some welding wire from weldingsupply because it is .81 per foot. I would love to know if anyone has done this before and what they thought. The wire i am looking at is 4 gague.

- i did almost 15 years ago it was ship and i like the wire the problem was engine noise for 3 months and i refuse to believe it was on a simple cable but once i replace it with 4 gauge normal inexpensive wire the noise was solve not a good idea

Send your message to us

Electro Galvanized Iron Wire Low Carbon Steel Factory Directly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches