Specifications &Feature:

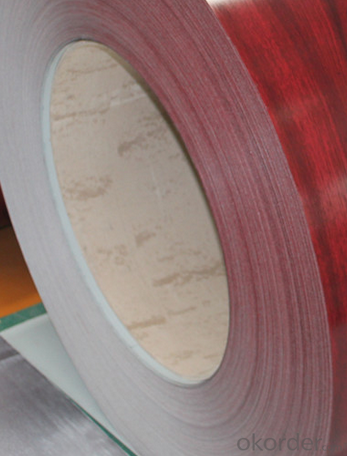

prepainted steel coils(pre-painted steel,steel coils):

Paint:PE,EP,PVDF,SMP,HDP.

Thickness:0.20mm-1.2mm

Width:700mm-1500mm

Prepainted Steel Coil Specifications:

Galvanized steel is hot or cold-rolled strip steel belt of substrates, through continuous hot-dip galvanizin process.It is good in corrosion resistance,high in surface quality, convenient in deep-processing,low cost. Widely used in silo,the fish up , the chimney, kitchen utensil, handicraft, construction formwork, household electrical appliance, roller shutter door, garage door, wave wattand colored substrate,etc.

Steel roll, also known as the coil.Steel hot press, cold press molding for roll shape.For the convenience of storage and transport, for all kinds of processing.Forming rolls are mainly hot rolled coil and cold rolled coil.Hot rolled hot is rolled coil, it was based on the slab after heating made strip roughing and finishing mill group.From finishing the last hot steel strip mill out through laminar flow cooling to the set temperature, which consists of the winder coil, steel coil after cooling, according to the different needs of users, after different finishing line processing and become a steel plate, flat roll and longitudinal cutting steel strip products, hot roll is in front of the billet recrystallization processing products, its material Q235B, Q345B, SPHC, 510 l, Q345A, Q345E.Cold rolled coil refers to directly use roll rolling at room temperature with a certain thickness and winding machine rolls into the whole volume of steel belt.Compared with hot-rolled coil, cold-rolled coil surface light, bright and clean degree is high, but will have more stress, often in the annealing treatment after cold rolling.Hot-rolled coil, cold-rolled coil is after processing, and its classification are (SPCC) SPCD SPCE.Steel coil general weight is about 15 to 30 t.