Thickness: 0.15 - 2.0 mm

Technique: Hot Rolled

Application: Container Plate

Surface Treatment: Galvanized

Secondary Or Not: Non-secondary

Certification: CE

Special Pipe: Thick Wall Pipe

Alloy Or Not: Non-alloy

Section Shape: Other

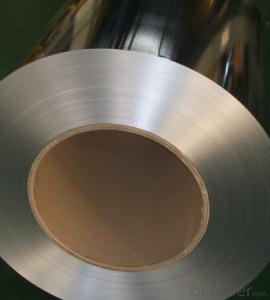

Galvanized Steel Coil Hot Dipped ss400 CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

| Product name | hot rolling galvanized steel coil |

| Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

| Certificate | ISO9001,BV,SGS |

| Thickness | 0.13mm-2.0mm |

| Width | 1250mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | galvanized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

| Anti-MEK Wiping | ≥100times |

| Zinc coating | 40-180g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | Silver |

| Application | construction material for building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: What are the common coil width tolerances?

- The common coil width tolerances vary depending on the industry and specific application. However, typical coil width tolerances range from +/- 0.005 to 0.030 inches.

- Q: How are steel coils inspected for coil weight accuracy?

- Steel coils are inspected for coil weight accuracy by using weighing scales or load cells to measure the weight of the coil. The coil is placed on the scale, and the weight is compared to the specified weight range provided by the manufacturer. If the weight falls within the acceptable range, the coil is considered accurate.

- Q: What are the challenges in coil blanking?

- Coil blanking, a process used to cut flat metal sheets from coiled stock, presents several challenges that need to be addressed for efficient and accurate production. Some of the key challenges in coil blanking include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality. These variations can affect the cutting process and result in inconsistent blanks. Proper material selection and control are crucial to ensure consistent quality and dimensional accuracy. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature). These imperfections can cause alignment issues during the cutting process, leading to misalignment and inaccurate blanks. Specialized equipment and techniques, such as straighteners and leveling systems, are required to minimize these shape imperfections. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Adequate edge conditioning techniques, such as deburring or edge trimming, need to be employed to ensure clean and straight edges for the final blanks. 4. Slitting and shearing forces: The forces exerted during the coil blanking process can induce stresses and strains in the material, potentially leading to deformation or springback. These factors can result in dimensional variations and affect the overall quality of the finished blanks. Careful consideration of the slitting and shearing forces, along with proper tooling design and machine settings, is necessary to minimize these effects. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and minimizing material waste are critical challenges in coil blanking to optimize production efficiency and reduce costs. Efficient nesting algorithms and real-time monitoring systems can help optimize material utilization and minimize waste. 6. Automation and productivity: Coil blanking processes often require high-speed and high-volume production to meet market demands. Implementing automation systems, such as robotic material handling and advanced control systems, can enhance productivity. However, integrating and synchronizing these automation components with the cutting process can be challenging and requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking requires a combination of proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: What are the different surface treatments applied to steel coils?

- Some of the different surface treatments applied to steel coils include galvanizing, which involves coating the steel with a layer of zinc to protect it from corrosion, painting or powder coating to enhance the aesthetics and provide additional protection, and passivation to remove any impurities on the surface and improve its corrosion resistance.

- Q: How are steel coils protected against bending and deformation?

- Steel coils are protected against bending and deformation through various measures. One common method is the use of protective packaging materials such as wooden crates or metal skids, which provide stability and support to prevent any bending or deformation during transportation or storage. Additionally, steel coils are often secured tightly using steel or plastic bands to maintain their shape and prevent any shifting or movement. These bands are strategically placed at regular intervals along the length and width of the coils to ensure even distribution of pressure and minimize the risk of bending or deformation. Moreover, steel coils can be further protected by placing them on a flat and level surface during storage or transportation. This helps to distribute the weight evenly and reduce the chances of any bending or deformation due to uneven pressure. In some cases, steel coils may also be coated with anti-corrosion agents to protect against moisture and rust, which can weaken the structure of the coils and lead to bending or deformation over time. Overall, a combination of proper packaging, secure fastening, and careful handling is essential to protect steel coils against bending and deformation, ensuring their structural integrity and quality.

- Q: What are the factors that affect the price of steel coils?

- The factors that affect the price of steel coils include supply and demand dynamics, fluctuations in raw material costs (such as iron ore and coal), changes in energy prices, market competition, import and export regulations, currency exchange rates, and overall economic conditions.

- Q: I remember my dad saying something about steel toed boots but I forgot =#92; I went and checked out all the stores and got a pair with good ankle support but they also have steel toes. Would this interfere with the shifter or anything? I figure if anything my dirt bike shoes have the steel toes too. Any opinion?

- I personally like to feel the shifter, and I've found that I can't feel the shifter as well through steel toed boots. Steel toed boots are designed to protect you in the event of something heavy dropping on your foot - which isn't very likely on a motorcycle. I have also found that in extreme cold that steel toed boots seem to act like a heat sink for your feet - non steel toed boots seem to stay just a little bit warmer. If you're a new rider, a very blunt toe (whether steel or not) can make getting your toes under the shifter a little more difficult, but with some practice and experience, you will get used to it. Honestly, I don't think it really makes all that much difference. All new riders have difficulty with the shifter, and it will take time for you to get used to it either way. I don't think the difference is really even worth going out and buying another set of boots, but yeah, if you were getting your first pair, I would tell you to look for a boot with a toe that is slender and tapered (vs. blunt), and non-steel.

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q: So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- Hi: okorder /

- Q: ...particularly for jewelry?

- Surgical stainless steel is a variation of steel usually consisting of an alloy of chromium (12–20%), molybdenum (0.2–3%), and sometimes nickel (8–12%). The chromium gives the metal its scratch-resistance and corrosion resistance. The nickel provides a smooth and polished finish. The molybdenum gives greater hardness, and helps maintaining a cutting edge. In metallurgy, stainless steel (inox) is defined as a ferrous alloy with a minimum of 10% chromium content.[1] The name originates from the fact that stainless steel does not stain, corrode or rust as easily as ordinary steel. This material is also called corrosion resistant steel when it is not detailed exactly to its alloy type and grade, particularly in the aviation industry

Send your message to us

Galvanized Steel Coil Hot Dipped ss400 CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords