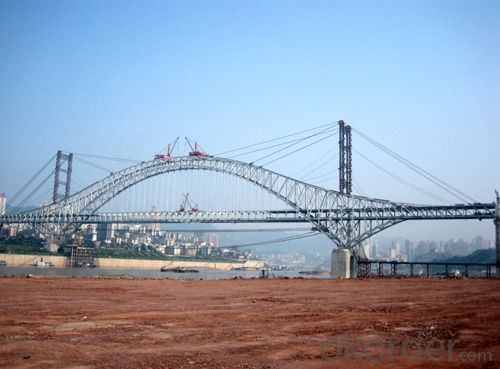

Customized steel structure for bridge

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

| Model Number | B |

| Material | Metal |

| Drawing for design | According to your requirement.We can quote according to your drawing. |

| Surface Treatment | Hot galvanized,painted,powder coated |

Packing Details

| a)Steel strip. |

| b)According to the customers' requirement |

Payments and Shipping Terms

| MOQ | 25 Ton |

| Supply Ability | 100 ton/Month |

| Payment Term | a)L/C b)T/T |

| FOB Shanghai Price | USD1000-1200/Ton |

Check Below for more imformation on placing an order

| 1. Inquiry-Professional quotation. |

| 2. Confirm the price, lead time, payment term etc. |

| 3. Our sales send the Proforma Invoice. |

| 4.Customer make the payment for deposit and send us Bank receipt. |

5.We will arrange the production & inform the estimated time. |

6. Middle Production:send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

7. End Production:Mass production products photos will send to you for approval. You can also arrange the third party Inspection. |

8. Clients make payment for balance and we Ship the goods .Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients. |

9. Order can be say “finish” when you receive the goods and satisfy with them . |

10. Feedback to us about Quality , Service, Market Feedback & Suggestion. And we will do better. |

- Q: What are the common design considerations for steel retaining walls?

- Some common design considerations for steel retaining walls include the required height and load-bearing capacity, the type and quality of steel used, the corrosion resistance and durability of the material, the method of connection and anchoring, the aesthetics and finish of the wall, and compliance with local building codes and regulations. Additionally, factors such as soil conditions, water drainage, and any potential impact on nearby structures or the environment should also be taken into account during the design process.

- Q: Is cast-in-place concrete attic good or steel structure + ALC board good?!

- The short cycle of cast-in-place steel structure high stability, light weight, does not destroy the original structure, anchorage hole cast-in-place the original wall hit double row hole spacing of ten cm each with adhesive implantation wall, wall depth of ten to fifteen cm, and the steel structure is not greater than the chemical anchor spacing bolt with wall of not less than thirty cm fifty cm fifteen cm deep into the root.

- Q: How are steel structures designed for different electrical systems?

- Steel structures are designed for different electrical systems by considering various factors such as load requirements, electrical equipment placement, grounding provisions, and safety regulations. The design process involves collaboration between structural engineers and electrical engineers to ensure that the steel structure can accommodate the specific electrical system's needs, such as cable routing, support for electrical panels, and provisions for conduits. The structural design also considers factors like electrical loads, vibrations, electromagnetic interference, and potential hazards to ensure the overall safety and performance of the electrical system within the steel structure.

- Q: Steel plate for steel structure, what kind of steel plate is it?

- The grades of carbon structural steel are composed of four parts: the yield strength, the letter Q, the yield strength value, the quality grade mark (ABCD), and the deoxidation method notation (FZTZ).

- Q: How do steel structures withstand seismic forces?

- Steel structures are able to withstand seismic forces due to their inherent strength and ductility. Steel has a high strength-to-weight ratio, allowing it to support heavy loads without compromising its integrity. Additionally, steel is highly ductile, meaning it can deform and absorb energy during an earthquake without fracturing. This ductility allows the structure to flex and dissipate seismic energy, reducing the likelihood of collapse. Moreover, steel structures can be designed with specific seismic-resistant features such as base isolation or bracing systems that further enhance their ability to withstand seismic forces.

- Q: How are steel structures designed for progressive collapse resistance?

- Steel structures can be designed for progressive collapse resistance by incorporating various measures. These measures include designing redundancy and robustness into the structure, using alternate load paths, providing additional reinforcement at critical connections, and employing blast-resistant design principles. Additionally, advanced computer simulations and analysis techniques are often employed to evaluate the structure's response to potential progressive collapse scenarios and ensure its resilience against such events.

- Q: What is the role of steel in building automation and control?

- The role of steel in building automation and control is to provide structural support and stability to the various components and systems involved. Steel is commonly used in the construction of building frames, beams, and columns, ensuring the overall strength and integrity of the structure. It also enables the installation and integration of automation and control systems, as steel can easily accommodate wiring, sensors, and other related equipment. Overall, steel plays a crucial role in creating a reliable and robust infrastructure for building automation and control.

- Q: How are steel structures used in the construction of food processing facilities?

- Steel structures are commonly used in the construction of food processing facilities due to their durability, strength, and ability to withstand harsh environmental conditions. These structures provide a stable framework for the facility, supporting heavy machinery and equipment, as well as ensuring the safety of workers and the integrity of the food processing operations. Additionally, steel structures can be easily customized and expanded to accommodate future growth and changes in the facility's layout, making them a cost-effective and flexible choice for food processing construction.

- Q: What are the different types of steel cladding and facade systems used in buildings?

- There are several types of steel cladding and facade systems used in buildings, including pre-fabricated panels, metal sheets, standing seam systems, and composite panels. These systems provide aesthetic appeal, weather protection, and structural support to the building, allowing for flexibility in design and durability.

- Q: How are steel structures designed for foundation settlement?

- Steel structures are designed for foundation settlement by implementing various measures such as flexible connections, deep foundations, and monitoring systems. Flexible connections allow the steel structure to accommodate minor settlement by providing a degree of flexibility between the foundation and the superstructure. Deep foundations, such as piles, are used to transfer the load of the structure to deeper, more stable soil layers, reducing the impact of settlement. Additionally, monitoring systems are installed to continuously assess and measure any settlement that may occur, allowing for timely interventions and adjustments to maintain the structural integrity of the steel structure.

Send your message to us

Customized steel structure for bridge

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords