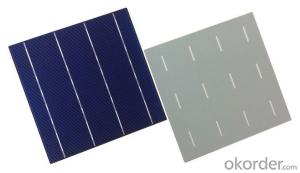

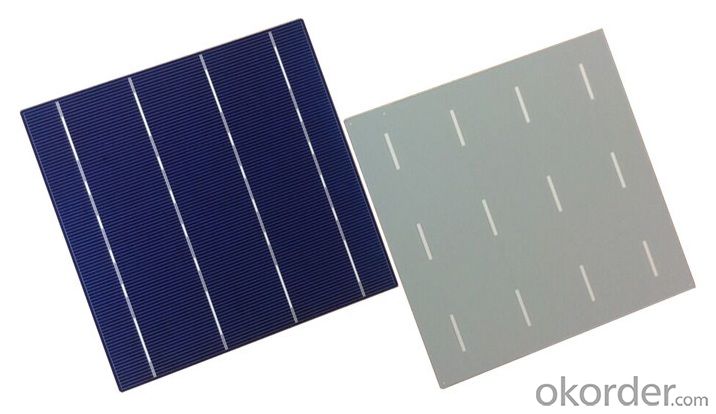

Crystalline Silicon Wafer Solar Cells - A Grade Polycrystalline Solar Cell 4.2W-4.3W

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A Grade Polycrystalline Solar Cell 4.2W-4.3W

Main Characteristic

17.6%-18% High Efficiency A Grade 125mm Monocrystalline Solar Cells

1.First-class production technology and packaging technology.

2.Adopting the world's leading technology of silicon and polycrystalline silicon cells, power density, peak hours more battery power, higher conversion efficiency.

3.Beautiful, stable, easy to take down the anodic aluminum frame electric degrees and has a wind-resistant, anti-snow function.

Features

17.6%-18% High Efficiency A Grade 125mm Monocrystalline Solar Cells

1.High transmissivity low-iron tempered glass, strong aluminium frame.

2.Manufactured according to international quality and Environment Management System (ISO9001, ISO14001).

3.Low voltage-temperature coefficient allows higher power output at high-temperature condition.

Product Pictures

Top 7 Reasons to Order From Us:

1) We offer you the best quality on the market!

2) We offer you strongly competitive prices !

3) We offer the fastest shipping !

4) we can accept small order!

5) we design various of watt according to cuatomer!

6) We have the best customer service team!

7) We have excellent manufacturer solar panel warranty policy!

- Q: What is the typical warranty period for a solar silicon wafer?

- The typical warranty period for a solar silicon wafer can vary, but it is commonly around 25 to 30 years.

- Q: How are solar silicon wafers tested for thermal properties?

- Solar silicon wafers are typically tested for thermal properties by subjecting them to a series of controlled heating and cooling cycles. This process involves placing the wafers in a controlled environment and gradually increasing the temperature while monitoring their response. The thermal conductivity, coefficient of thermal expansion, and other relevant parameters are measured to assess the wafers' thermal properties. Additionally, specialized equipment like thermal imaging cameras may be used to detect any hotspots or temperature variations across the wafer's surface during testing.

- Q: What is the cost of manufacturing a solar silicon wafer?

- The cost of manufacturing a solar silicon wafer can vary depending on various factors such as the size, quality, and production volume. However, on average, the cost can range from a few dollars to around $10 per wafer.

- Q: Can solar silicon wafers be used in solar-powered charging stations?

- Yes, solar silicon wafers can be used in solar-powered charging stations. These wafers are the primary component of solar cells, which convert sunlight into electricity. Solar-powered charging stations utilize solar cells to capture sunlight and generate electricity for charging various devices, making them a suitable choice for such applications.

- Q: How are solar silicon wafers protected from chemical damage during manufacturing?

- Solar silicon wafers are typically protected from chemical damage during manufacturing through various methods. One common approach involves applying a thin layer of protective material, such as silicon nitride, on top of the wafer surface. This layer acts as a barrier, shielding the silicon from potentially harmful chemicals or contaminants. Additionally, cleanrooms with controlled environments are utilized to minimize the presence of any harmful substances that could cause chemical damage.

- Q: Can solar silicon wafers be used in solar-powered electric fences?

- Yes, solar silicon wafers can be used in solar-powered electric fences. These wafers are commonly used in solar panels to convert sunlight into electricity, which can then be used to power various devices, including electric fences. By utilizing solar silicon wafers, solar-powered electric fences can operate independently from the grid, making them more eco-friendly and cost-effective.

- Q: What is the average reflectivity of a solar silicon wafer?

- The average reflectivity of a solar silicon wafer is typically around 30%.

- Q: Can solar silicon wafers be used in other electronic devices?

- Yes, solar silicon wafers can be used in other electronic devices. While they are primarily used in solar panels to convert sunlight into electricity, they can also be used in various other electronic applications such as sensors, integrated circuits, and batteries. The properties of solar silicon wafers, such as their high purity and efficient light absorption, make them suitable for a wide range of electronic devices beyond just solar panels.

- Q: What are the main factors that affect the cost of a solar silicon wafer?

- The main factors that affect the cost of a solar silicon wafer include the raw material costs, manufacturing processes, economies of scale, technological advancements, and market demand.

- Q: How are defects in solar silicon wafers detected?

- Defects in solar silicon wafers are typically detected using various techniques such as visual inspection, infrared imaging, and electrical testing. Visual inspection involves examining the wafer's surface for visible imperfections, such as cracks, scratches, or impurities. Infrared imaging can identify defects by measuring the heat distribution across the wafer, as irregularities often generate different thermal patterns. Electrical testing is conducted by applying a voltage or current to the wafer and analyzing its response to identify any anomalies or abnormalities. These techniques allow manufacturers to identify and remove defective wafers, ensuring the production of high-quality solar cells.

Send your message to us

Crystalline Silicon Wafer Solar Cells - A Grade Polycrystalline Solar Cell 4.2W-4.3W

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords