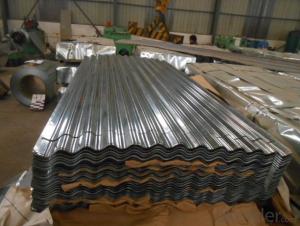

Corrugated Hot-Dipped Galvanized Steel-Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

Pressing steel panel can be freely incised, it can satisfy the especially designing demands. It apply on convenient construction, and anti-seismic performance, fire proof, waterproof, free of maintenance, ect.

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Application:

Roofing and walling, curved profiles, corrugated sheets, foamed sandwich panels for roofing and walling, roof tills, rainwater gutter, metal doors, garage doors, wall panels for partitions, ceiling panels, suspended frames, interior metal doors or windows, profiles for exterior cabinets of white appliances, office furniture, home appliances, etc.

Product Specification:

1) Standards: JIS G3302 1998 or ASTM A653M / A924M 1998

2) With excellent weather resistance

3) Suitable for partitions, vending machinery, decks, scaffolding, purlin, gurdrail, suspension bar for ceiling and so on

4) Specification: SPCC, SGCC, SGCH, SGCD, SGHC, (CS, SS, DDS)

5) Thickness: 0.14mm-50mm

6) Width: 20mm - 1250mm

7) Zinc coating: Z08, Z12, Z18, Z20, Z22, Z25, Z27.Z100 Z275

8) Surface finish: Regular spangle, minimized spangle, zero spangle

9) Surface treatment: Chromating treatment, anti-finger print

10) Inner diameter: 508mm / 610mm

11) Outer diameter: 2, 000mm max .

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel ,sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. Could you produce the sheets according to our design?

Yes, we can.

- Q: What are the different types of steel sheet patterns?

- In various industries, one can find a variety of steel sheet patterns commonly used. Among the most popular ones are: 1. Plain Steel Sheet: This type of steel sheet pattern is the simplest and most basic. It has a smooth surface without any visible texture or pattern. 2. Diamond Pattern Steel Sheet: The surface of this steel sheet is embossed or raised in a diamond-shaped pattern. It is commonly used in applications where slip resistance is important, such as walkways and stair treads. 3. Perforated Steel Sheet: These sheets are created by punching holes in the steel to form a pattern of openings. They are commonly used for ventilation, filtration, and decorative purposes. 4. Corrugated Steel Sheet: With a wavy appearance due to parallel ridges and grooves, corrugated steel sheets offer added strength and rigidity. They are suitable for roofing and siding applications. 5. Checkered Steel Sheet: This type of steel sheet features a pattern of raised squares or rectangles, similar to a chessboard. It is commonly used for flooring, stairs, and decorative purposes. 6. Hammered Steel Sheet: Hammering the surface of the steel sheet creates a unique texture, giving it a rough and rustic appearance. It is often used for decorative purposes, adding a distinct visual appeal to various applications. 7. Brushed Steel Sheet: Achieved by rubbing the surface with an abrasive material, brushed steel sheets have a brushed or satin-like finish. This pattern provides a smooth and uniform appearance, commonly used in architectural and decorative applications. These examples showcase the different types of steel sheet patterns available. Each pattern possesses its own unique characteristics and applications, offering a wide range of uses in various industries.

- Q: What are the dimensions of the steel sheets?

- The dimensions of the steel sheets can vary depending on the specific requirements or intended use. Steel sheets are commonly available in standard sizes such as 4 feet by 8 feet or 1 meter by 2 meters. However, they can also be customized to different dimensions based on the needs of the project. It is important to specify the desired length, width, and thickness when ordering steel sheets to ensure they meet the required specifications.

- Q: What are the limitations of using steel sheets?

- One limitation of using steel sheets is their susceptibility to corrosion, especially when exposed to moisture or certain chemicals. Additionally, steel sheets can be heavy and require special equipment for handling and installation. They also have limited flexibility and may crack or break under excessive stress or bending. Moreover, steel sheets may be more expensive compared to other materials, making them less cost-effective in certain applications.

- Q: What are the different bending radius options for steel sheets?

- The bending radius possibilities for steel sheets can differ based on the thickness and type of steel used. In general, the bending radius for steel sheets ranges from 0.5 to 2 times the sheet thickness. For thinner sheets, such as those measuring 0.5mm to 2mm in thickness, it is typically advised to use a bending radius of 0.5 to 1 times the sheet thickness. This allows for a tighter bend without risking the steel cracking or deforming. For thicker sheets, like those measuring 2mm to 6mm in thickness, it is common to utilize a bending radius of 1 to 1.5 times the sheet thickness. This ensures that the steel retains its structural integrity and prevents excessive stress or strain during the bending process. For even thicker sheets, usually above 6mm in thickness, a bending radius of 1.5 to 2 times the sheet thickness is often necessary. This larger bending radius helps prevent any potential damage or distortion to the steel, ensuring a successful bending operation. It is important to note that these bending radius options are general guidelines and may vary depending on the specific grade, composition, and intended application of the steel. It is always recommended to consult the manufacturer's recommendations or seek expert advice when determining the appropriate bending radius for steel sheets.

- Q: Are the steel sheets resistant to oil or grease?

- Steel sheets are resistant to oil or grease in general. Steel is renowned for its durability and ability to withstand different chemicals, such as oil and grease. Due to the sleek surface of steel sheets, it becomes challenging for substances like oil or grease to stick to them, which facilitates effortless cleaning and maintenance. Moreover, if necessary, steel sheets can undergo additional treatment or be coated with protective substances to enhance their resistance to oil or grease.

- Q: Are the steel sheets suitable for HVAC applications?

- Yes, steel sheets are suitable for HVAC applications. Steel is a strong and durable material that can withstand high temperatures and mechanical stress, making it ideal for use in heating, ventilation, and air conditioning systems. Steel sheets are commonly used to fabricate HVAC components such as ducts, plenums, and air handling units. They offer excellent corrosion resistance, which is essential for maintaining the quality and longevity of HVAC systems. Steel sheets can be easily formed and welded, allowing for customization and efficient installation. Overall, the use of steel sheets in HVAC applications ensures reliable performance and longevity of the system.

- Q: Are the steel sheets resistant to staining or discoloration?

- Yes, steel sheets are highly resistant to staining or discoloration.

- Q: Are steel sheets resistant to bullet penetration?

- Yes, steel sheets are generally resistant to bullet penetration due to their high hardness and strength. However, the degree of resistance may vary depending on the thickness and quality of the steel.

- Q: Can steel sheets be used for storage racks or shelving?

- Yes, steel sheets can be used for storage racks or shelving. Steel sheets are durable, strong, and resistant to damage, making them suitable for heavy-duty storage applications. Additionally, their versatility allows for customization and various configurations to meet specific storage needs.

- Q: Can steel sheets be used for pressure vessels?

- Yes, steel sheets can be used for pressure vessels. Steel is a strong and durable material that can withstand high pressure and provide structural integrity to pressure vessels. It is commonly used in various industries such as oil and gas, chemical, and manufacturing for constructing pressure vessels due to its excellent mechanical properties and corrosion resistance.

Send your message to us

Corrugated Hot-Dipped Galvanized Steel-Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords