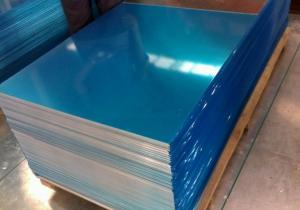

301 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

grade | 301 |

surface | 2B |

thickness | 1MM, |

width | 1200MM,1220MM,1500MM,ETC. |

length | 2400MM,2440MM,3000MM,ETC. |

Payment terms | T/T, or L/C. |

Delivery time | Normally within 1 weeks after get your deposits. |

package | Standard export package, normally with wooden pallets |

MOQ | 5 tons/each size |

- Q: How do you prevent crevice corrosion in stainless steel sheets?

- To prevent crevice corrosion in stainless steel sheets, there are a few key measures that can be taken: 1. Proper design and fabrication: Ensure that the stainless steel sheets are designed and fabricated with smooth surfaces and minimal crevices. This will reduce the potential for stagnant solution entrapment and minimize the risk of crevice corrosion. 2. Regular cleaning and maintenance: Regularly clean the stainless steel sheets to remove any debris or contaminants that can promote crevice corrosion. This can be done using mild detergents or specialized stainless steel cleaners. 3. Avoid exposure to corrosive environments: Limit the exposure of stainless steel sheets to corrosive environments, such as those containing chloride ions (e.g., saltwater). If exposure is unavoidable, consider applying protective coatings or using higher-grade stainless steel alloys that are more resistant to crevice corrosion. 4. Control the environment: Maintain proper environmental conditions, such as controlling temperature, humidity, and pH levels, to minimize the risk of crevice corrosion. Monitoring and controlling these factors can help create a less conducive environment for corrosion to occur. 5. Regular inspections and maintenance: Conduct regular inspections to identify any signs of crevice corrosion, such as discoloration, pitting, or rough surfaces. If any corrosion is detected, take immediate action to remove it and repair the affected area. By implementing these preventive measures, you can significantly reduce the risk of crevice corrosion in stainless steel sheets, ensuring their longevity and performance.

- Q: What are the specifications of stainless steel plates? Are they the same width?

- Generally look at the thickness of 0.3-3.0mm, width of 1000/1219/1500. Thickness of 3 or more, with 1240/1250/1500/1800/2000 width. It can be cut as required.... So the purchase is still more flexible.

- Q: Can stainless steel sheets be used in food processing?

- Food processing can make use of stainless steel sheets. They are commonly chosen in the food industry because of their advantageous properties. One crucial property is their resistance to corrosion, which is highly important in food processing environments where contact with water, chemicals, and food is frequent. Stainless steel sheets are also non-reactive, meaning they do not interact with food or impact its taste, thus making them a safe option for food processing equipment. Moreover, stainless steel is easy to clean and maintain, making it ideal for maintaining the high levels of hygiene required in food processing facilities. Its durability and strength ensure that it can withstand the demanding nature of food processing operations. Overall, stainless steel sheets are the preferred choice in the food industry for their suitability in food processing applications.

- Q: How can I classify stainless steel plates?

- The stainless steel plate in accordance with the classification of surface features can be divided into: silver white matte (use does not need to have a surface gloss), bright as a mirror (building materials, kitchen utensils), coarse grinding fine grinding / polishing / intermediate / fine grinding (building materials, kitchen utensils), hairline grinding (buildings, building materials), close to the mirror grinding (art, decoration), mirror grinding (mirror, decorative).

- Q: Can stainless steel sheets be used for architectural wire mesh?

- Yes, stainless steel sheets can be used for architectural wire mesh. Stainless steel is a durable and corrosion-resistant material, making it suitable for various architectural applications, including wire mesh installations. It offers strength, versatility, and an attractive appearance, making it an ideal choice for creating functional and aesthetically pleasing architectural wire mesh designs.

- Q: What are the different types of brushed finishes available for stainless steel sheets?

- There are several types of brushed finishes available for stainless steel sheets, including satin, mirror, hairline, and bead blasted finishes.

- Q: What are the different types of stainless steel sheet surface textures available?

- Some of the different types of stainless steel sheet surface textures available include brushed, mirror, embossed, and patterned.

- Q: What are the benefits of using embossed stainless steel sheets?

- Using embossed stainless steel sheets has several advantages. Firstly, these sheets offer a heightened aesthetic appeal. The unique textures and visual interest created by the embossed patterns on the surface can transform any space, giving it a more modern and visually appealing look. This is applicable to both residential and commercial settings. In addition, embossed stainless steel sheets provide enhanced durability and strength. Stainless steel is already known for its resistance to corrosion, staining, and wear. The embossing process further reinforces the sheets, making them suitable for high traffic areas or places where damage or impact may occur. Moreover, embossed stainless steel sheets are incredibly versatile. They can be used in various applications, such as wall cladding, elevator panels, kitchen backsplashes, furniture, and architectural features. These sheets are easy to cut and shape, allowing for flexibility in design requirements. Furthermore, maintaining embossed stainless steel sheets is hassle-free. The smooth surface of the embossed patterns makes it easy to clean away dirt, grime, and fingerprints, ensuring a hygienic and spotless surface. This is particularly beneficial in areas that require high cleanliness standards, like kitchens or healthcare facilities. Lastly, embossed stainless steel sheets are environmentally friendly. Stainless steel is a highly sustainable material as it is 100% recyclable. The embossing process itself does not generate any waste or harmful byproducts, making these sheets an eco-friendly choice for those who want to reduce their carbon footprint and contribute to a greener environment. In conclusion, the advantages of using embossed stainless steel sheets include enhanced aesthetic appeal, increased durability and strength, versatility in applications, easy maintenance, and eco-friendliness. These sheets are an excellent option for individuals seeking a durable, stylish, and sustainable material for their projects.

- Q: 304 stainless steel plate 1*1219*C what do you mean?

- Roll thickness 1 mm, width 1219 mm, length is unlimited (depending on volume weight). 304 stainless steel is a kind of the most commonly used, law-abiding.

- Q: Are stainless steel sheets suitable for architectural panels?

- Architectural panels can indeed be made from stainless steel sheets, which offer a plethora of benefits. Stainless steel is a remarkably versatile and durable material that is resistant to corrosion, staining, and rust. This makes it an excellent choice for exterior applications, where exposure to harsh weather conditions is expected. Furthermore, stainless steel maintains its appearance over time, ensuring that architectural panels retain their aesthetic appeal for many years. What sets stainless steel apart is its capacity to offer a wide range of design possibilities. It can be fabricated into various shapes and sizes, allowing for the creation of unique and visually captivating architectural panels. Architects and designers can also choose from different finishes, including brushed, polished, or patterned, to achieve the desired look and feel for their projects. Moreover, stainless steel is environmentally friendly due to its full recyclability. By opting for stainless steel sheets for architectural panels, architects and designers can contribute to reducing the environmental impact of construction projects. All in all, stainless steel sheets provide an exceptional combination of strength, aesthetics, and sustainability, making them highly suitable for architectural panels. Whether it be for exterior cladding, interior partitions, or decorative elements, stainless steel offers a durable, versatile, and visually appealing solution for architectural design.

Send your message to us

301 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords