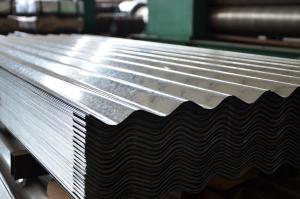

Galvalume Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We specialize in manufacturing galvanized steel coil, galvalume steel coil, prepainted steel coil and galvanized corrugated sheets.

Nowadays our company has grown up to a collectivized company . We are grateful to the cooperation partner who`s grown with us all the way. We hope we could make more friends from all over the world. Under the joint efforts of both sides we believe that we will continue to achieve win-win results based on mutual trust and mutual support.

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Special Use: | Width: | |||

| Length: | Based Material: | Material: | |||

| Zinc Coated: | Spangle: | Shape: | |||

| Galvanized Type: | Business: | Payment Terms: | |||

| Packaging: | Delivery Detail: |

Packaging & Delivery

| Packaging Detail: | Fully seaworthy export packing with paper tube Each coil is wrapped in water-proof paper. |

| Delivery Detail: | about 15 days after the deposit if the quantity below 500 ton. |

Specifications

Corrugated gi/gl/ppgi Sheet

1.Thickness: 0.13mm-1.0mm

2.Width:750mm-1250mm

3. z40-z150g/m2

4.ISO 2000,SGS

- Q: Can steel sheets be used for making staircases?

- Staircases can indeed be made using steel sheets. Steel, being a robust and long-lasting material, is capable of withstanding significant weights, making it ideal for constructing staircases. By utilizing steel sheets, staircases are provided with a secure base and structural soundness, thereby guaranteeing both safety and durability. Moreover, steel allows for effortless shaping and molding into diverse designs, enabling a wide range of options for staircase aesthetics. Whether for residential, commercial, or industrial purposes, steel sheets are highly favored in the construction of staircases due to their exceptional strength, durability, and adaptability.

- Q: Can the steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding due to their high magnetic permeability, which helps to redirect and absorb magnetic fields.

- Q: Are steel sheets suitable for railway carriages?

- Yes, steel sheets are suitable for railway carriages. They provide strength, durability, and resistance to wear and tear, making them an ideal choice for the construction of railway carriages.

- Q: Are steel sheets suitable for sports stadiums or arenas?

- Yes, steel sheets are suitable for sports stadiums or arenas. Steel is a strong and durable material that can withstand heavy loads and provide structural support. It is commonly used in the construction of large-scale buildings like sports stadiums due to its strength, versatility, and cost-effectiveness. Additionally, steel sheets can be customized to meet specific design requirements and can be easily assembled on-site, making them an ideal choice for sports stadium construction projects.

- Q: Are steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications. Steel is highly durable, weather-resistant, and can withstand harsh environmental conditions, making it an excellent choice for outdoor usage.

- Q: Are steel sheets suitable for laser cutting or engraving?

- Yes, steel sheets are suitable for laser cutting and engraving. The high intensity laser can easily cut through steel sheets, while engraving techniques can be used to create intricate designs or markings on the surface of the steel.

- Q: What are the different coating options for steel sheets (powder coating, paint, etc.)?

- Some of the different coating options for steel sheets include powder coating, paint, galvanized coating, and metal plating.

- Q: What are the different surface textures for galvanized steel sheets?

- The different surface textures for galvanized steel sheets include smooth, matte, and patterned textures.

- Q: Are the steel sheets corrosion-resistant?

- Yes, steel sheets are corrosion-resistant due to their composition and protective coatings.

- Q: Are steel sheets prone to warping or buckling?

- Yes, steel sheets are prone to warping or buckling under certain conditions such as high temperatures, uneven cooling, excessive load, or inadequate support. However, the degree of susceptibility depends on the thickness, quality, and type of steel used. Proper installation, handling, and maintenance can minimize the risk of warping or buckling in steel sheets.

Send your message to us

Galvalume Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords