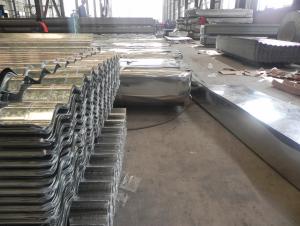

prepainted GL corrugated steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,SGHC,DX51D.. | Thickness: | 0.14-3.0mm |

| Place of Origin: | Shanghai China (Mainland) | Brand Name: | Model Number: | 600-1250mm | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | coated ,galvanized |

| Application: | building ,house,construction | Special Use: | Wear Resistant Steel | Width: | 600-1250mm |

| Length: | Any length | sample: | free available | quality: | first class |

| stock: | 5766tons | company type: | manufacturer & exporter | product name: | prepainted galvanized corrugated steel sheet |

Packaging & Delivery

| Packaging Detail: | 1.packed in bundles 2.waterproof packing 3.packed by steel strip 4.as per to clients |

| Delivery Detail: | within 5-20 days after receipt deposit or L/C at sight. |

Specifications

prepainted galvanized corrugated sheel sheet

1.Thickness:0.14-3.0mm

2.Width:600-1250mm

3.In stock

4.Fast delivery

prepainted galvanized corrugated steel sheet | |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | DX51D SGCC, DC51D,SPCC |

Thickness | 0.14-3.0mm |

Width | 600-1250mm(1250,1220,1000, 980mm, 900mm ,840mm, 820mm, 750mm) |

Coating | PE ,PVDF, HDP ,galvanized(30-300g), galvalume (AZ80) |

Color | According to RAL card |

Length | cut as client’s request, but considering the transportation , its better to cut less than 5.8 meter (for 20’ft container) , or 11.8 meter (for 40’ft container). |

Remarks | 1.Payment terms:T/T, L/C 2.Trade terms:FOB, CNF, CIF 3.Port:Shanghai 4.Supply ability:5000Tons/month 5.Delivery time: within 15-20 days after receiving the deposit. |

- Q: What is the process of polishing steel sheets?

- The process of polishing steel sheets involves several steps to achieve a smooth and shiny finish. First, the steel sheets are cleaned to remove any dirt, oil, or debris that may be present on the surface. This is typically done using a degreaser or a solvent. Next, the sheets are sanded using abrasive materials, such as sandpaper or a sanding belt. This step helps to remove any visible scratches or imperfections on the surface of the steel. After sanding, the sheets are typically polished using a polishing compound or paste. This compound is applied to the surface and rubbed in with a cloth or a buffing wheel. The polishing compound helps to remove any remaining scratches and brings out the natural shine of the steel. Once the initial polishing is complete, a finer polishing compound may be used to further enhance the shine and smoothness of the steel sheets. This step is repeated until the desired level of polish is achieved. Finally, the sheets are thoroughly cleaned and inspected to ensure that they meet the desired quality standards. This may involve removing any remaining polishing compound residue and checking for any remaining imperfections. Overall, the process of polishing steel sheets requires careful cleaning, sanding, and polishing to achieve a smooth and shiny finish. The specific techniques and materials used may vary depending on the desired level of polish and the type of steel being polished.

- Q: Are the steel sheets magnetic?

- Yes, steel sheets are magnetic. Steel is primarily composed of iron, which is a ferromagnetic material. This means that it can be magnetized and attracts other magnetic materials. Steel sheets are often used in applications where magnetic properties are required, such as in the manufacturing of magnets, electrical appliances, and various industrial equipment.

- Q: What is the maximum temperature resistance of steel sheets?

- The maximum temperature resistance of steel sheets varies depending on the specific type of steel and its composition. However, in general, stainless steel has good heat resistance and can withstand temperatures up to about 1200 degrees Celsius (2200 degrees Fahrenheit) without losing its strength or structural integrity. High carbon steels, on the other hand, can handle temperatures up to about 900 degrees Celsius (1650 degrees Fahrenheit) before they start to lose their mechanical properties. It is important to note that these temperature limits are approximate and may vary depending on factors such as the duration of exposure, the presence of other elements or impurities in the steel, and the specific application in which the steel sheets are being used. Therefore, it is always advisable to consult the manufacturer's specifications or conduct further research to determine the exact maximum temperature resistance of a particular type of steel sheet.

- Q: Can steel sheets be used in outdoor applications?

- Yes, steel sheets can be used in outdoor applications. Steel is a highly durable and weather-resistant material, making it suitable for various outdoor purposes such as roofing, siding, fencing, and construction projects. Its strength and resistance to corrosion make it an ideal choice for enduring harsh weather conditions and providing long-lasting performance.

- Q: Are steel sheets suitable for solar panel frames?

- Yes, steel sheets are suitable for solar panel frames. Steel is a durable and strong material that can provide the necessary support for solar panels, ensuring their stability and longevity. Additionally, steel sheets can be easily fabricated and customized to meet specific design requirements, making them a popular choice for solar panel frames in various applications.

- Q: What are the common finishes available for steel sheets?

- The common finishes available for steel sheets include hot rolled, cold rolled, galvanized, and coated finishes.

- Q: What are the properties of deep drawing properties in sheet steel?

- If the performance is different on the plane, the ear will appear. On the thickness of the performance is not good, there will be leakage phenomenon. Generally, deep drawing properties are indicated by R values.

- Q: Can the steel sheets be easily cleaned?

- Yes, steel sheets can be easily cleaned. Steel is known for its durability and ease of maintenance. It can be wiped clean using a damp cloth or sponge with mild soap or detergent. For tougher stains or grime, a non-abrasive cleaner can be used. Additionally, steel sheets are resistant to rust and corrosion, making them suitable for various environments and easy to maintain in the long run.

- Q: What is the typical hardness of a steel sheet?

- The typical hardness of a steel sheet varies depending on the specific grade and type of steel being used. However, steel sheets typically have a hardness ranging from 40 to 65 on the Rockwell C scale.

- Q: What is the price range for steel sheets?

- The price range for steel sheets can vary greatly depending on factors such as the size, thickness, quality, and market conditions. However, generally speaking, steel sheets can range anywhere from $30 to $150 per sheet.

Send your message to us

prepainted GL corrugated steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords