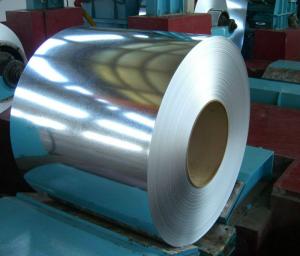

Prime Hot dip galvanized steel coil and sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technicaldata :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

|

|

|

|

|

| |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: I was looking at my Great-Grandfather's immigration form from when he immigrated from Scotland and he listed his occupation as a steel dresser. What does a steel dresser do?

- I'm not sure, but it could be like and engineer working in steel design or steel polisher. I checked Wikipedia and Yahoo but found nothing. It may be a description of something only in Scotland. Sorry

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- WD40 is great for cleaning stainless steel anything for some reason it protects it from finger prints things so you won't have to clean it as often. WD40 is great for thousands of other uses too, it can remove stickers, dried paint from glass, wipes away crayon wax, lubricates squeeky parts, spray it on your lawnmower or bike before you put it away for winter it'll come out in spring rust free.... so you'll get more than your moneys worth from a small tin.

- Q: How do steel coils contribute to the manufacturing of construction materials?

- The manufacturing of construction materials heavily relies on steel coils, as they serve as a flexible and dependable source of raw material. These coils, made from top-notch steel, are commonly used as a primary input in diverse construction processes. One of the key advantages of steel coils in construction material manufacturing lies in their adaptability to be shaped and formed into different products. These coils can be easily cut, bent, and molded, enabling the creation of a wide array of construction materials such as beams, pipes, and sheets. This flexibility empowers manufacturers to produce tailor-made construction components that fulfill specific project requirements. Moreover, steel coils provide construction materials with strength and durability. Steel is renowned for its exceptional tensile strength, making it an ideal choice for load-bearing structures and components. By employing steel coils, manufacturers can fabricate construction materials capable of withstanding heavy loads, extreme weather conditions, and other environmental factors, ensuring the longevity and safety of the final construction product. Additionally, steel coils offer consistency in both quality and performance. The manufacturing process of steel coils adheres to rigorous quality control measures, guaranteeing that the final product meets the necessary specifications. This uniformity in quality instills construction material manufacturers with the confidence to consistently produce reliable and high-performance products. Steel coils also play a role in enhancing the efficiency of construction material manufacturing. The availability of steel coils in large quantities and standardized dimensions allows for streamlined production processes. Manufacturers can optimize their operations by utilizing automated machinery and processes, reducing production time and costs, and increasing overall efficiency. In conclusion, steel coils are an indispensable component in the manufacturing of construction materials. Their versatility, strength, consistency, and efficiency make them the preferred choice for construction material manufacturers. By utilizing steel coils, manufacturers can create construction materials of superior quality and reliability, contributing to the safety, durability, and aesthetics of various construction projects.

- Q: I want to know if Diamond is stronger than Steel.

- What Is Stronger Than Diamond

- Q: Can steel coils be transported by air?

- Yes, steel coils can be transported by air. Air freight companies have the capability to transport heavy and oversized cargo, including steel coils, using specialized aircraft and equipment. However, due to their weight and size, transporting steel coils by air can be more expensive compared to other modes of transportation such as sea or rail.

- Q: ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- Look for buffing compound at the hardware store. Home depot lowe's od even Wal-mart/ There is a compound for steel and for iron. I t will not make iron real shinny but it will make it look good. This stuff is to be used with a buffing wheel but I have used it on rags and it work great.

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing through visual inspection, magnetic particle inspection, or ultrasonic testing. Visual inspection involves examining the surface for any visible defects such as scratches, dents, or corrosion. Magnetic particle inspection uses magnetic fields and iron particles to detect surface cracks or defects that may not be visible to the naked eye. Ultrasonic testing involves using high-frequency sound waves to detect internal and surface defects in the steel coils. These inspection methods help ensure the quality and integrity of the steel coils before they are further processed or delivered to customers.

- Q: How are steel coils used in the production of steel pipes?

- Steel coils are an essential component in the production of steel pipes. These coils serve as the raw material that is used to manufacture the pipes. The first step in the process involves unwinding the steel coil and feeding it into a machine called a slitter. The slitter cuts the coil into narrower strips of the desired width. This width is crucial as it determines the diameter of the steel pipes that will be produced. Once the steel coil has been slit into strips, the next step is to feed these strips into another machine called a forming mill. The forming mill gradually shapes the strips into a cylindrical shape by passing them through a series of rollers. These rollers apply pressure and bend the strips until they take on the form of a pipe. To ensure the durability and strength of the pipes, they undergo a welding process. The ends of the strip are heated and fused together using a high-frequency electric current, resulting in a continuous weld along the length of the pipe. This weld provides structural integrity and prevents any leakage or weak spots in the pipe. After the welding process, the pipes go through a sizing and shaping process. They are passed through additional rollers and gradually reshaped to achieve the desired dimensions, including the final outer diameter and wall thickness. Finally, the pipes are cut to the desired length and undergo various finishing processes such as straightening, testing, and coating. These finishing steps ensure that the pipes meet the required specifications and are ready for use in various applications, such as plumbing, construction, and oil and gas industries. In summary, steel coils are the starting point for the production of steel pipes. They are slit, formed, welded, sized, shaped, and finished to create durable and high-quality pipes that can be used in a wide range of industries.

- Q: What are the safety precautions when handling steel coils?

- The safety precautions when handling steel coils include wearing appropriate personal protective equipment such as gloves, safety boots, and eye protection to prevent injuries. It is important to use proper lifting techniques and equipment to avoid strains or back injuries. Coils should be stored in a stable manner to prevent them from falling or causing accidents. Additionally, workers should be trained on the proper handling procedures and be aware of their surroundings to prevent any potential hazards.

- Q: Does Steel Cut Oatmeal have the same health benefits as Old Fashioned Oatmeal? What is the difference in processing?

- Steel Cut Oats Steel-cut oats are whole oat kernels cut into small chunks rather than being smashed flat as in oatmeal. This gives the oats more of a chew texture and also slows both cooking time and digestion time. That means that they have a lower glycemic index and are thus preferable for increasing satiety, lowering the insulin response to the meal, and keeping blood sugar levels from peaking. This also results in delaying hunger so a person is less likely to snack or get overly hungry before the next meal. Here is how I like to cook oats for breakfast. Ingredients 1/2 cup Dry steel cut oats 1 cup Water (You may want a little more than a cup, experiment to your liking) 2 T Raisins (optional or replace with chopped dried apricots etc.) 2 T Ground flax meal (optional, but high in healthy n-3 fatty acids and fiber) Salt to your taste (try Lite salt to lower sodium intake) 2T Sunflower seeds or almonds 1 cup Fresh berries or a banana Directions Heat water to a boil. While water is heating, add the salt, raisins, and flax meal. When the water boils, add the steel cut oats. Stir once. Turn heat down to simmer and cook covered for 7-8 minutes. Provides two small servings. Double for large servings or small servings for 4 people. Serve and eat while hot. Add soy milk or low fat milk. Slice fresh fruit on top to add extra flavor. My wife likes banana slices. I like fresh berries, peaches, or sugar free applesauce. For extra crunch sprinkle almonds or sunflower seeds on top.

Send your message to us

Prime Hot dip galvanized steel coil and sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords