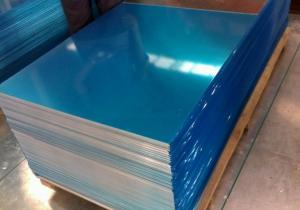

301 cold rolled stainless steel plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of 301 STAINLESS STEEL SHEET.

STAINLESS STEEL SHEET IS ONE POPULAR PRODUCTS IN CHINA MARKET, IT HAVE SEVERAL DIFFERENT APPLICATIONS, SUCH AS, CONSTRUCTION, BUILDING, DECORATION, ETC.

THE GRADE ALSO INCLUDE: 200 SERIES, 300 SERIES, 400 SERIES, ETC.

Mainly applied in the industry of furniture, sports equipment, compressed containers, shipbuilding, railway and the automotive.

2、Main Features of the 304 STAINLES STEEL SHEET.

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Wide applicability.

Length per spool only for reference

Spool Size Weight Specifications

D300mm 6Kg~7Kg 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm

5、FAQ of 301 STAINLESS STEEL SHEET.

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the different types of stainless steel sheet edges?

- Stainless steel sheets come in three main types of edges: mill edge, slit edge, and deburred edge. 1. The mill edge is the most common type and is produced during manufacturing. It has a rough, unfinished edge that is typically straight and perpendicular to the sheet's surface. It is suitable for applications where a smooth edge is not necessary. 2. Slit edge sheets are created by cutting large rolls of stainless steel into narrower widths. These edges are smoother and more precise compared to the mill edge. They are commonly used in applications that require a polished and precise edge, such as architectural finishes or fabrication processes. 3. A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to improve safety during handling or installation. Deburring can be done through grinding, sanding, or using specialized tools. The resulting edge is smooth and free from burrs or sharp protrusions. It's important to consider the specific application and requirements when choosing the edge type for a stainless steel sheet. Each type has its own advantages and limitations, and factors like aesthetics, functionality, and safety should be taken into account when selecting the appropriate edge for a project.

- Q: What are stainless steel sheets made of?

- Stainless steel sheets are primarily made of iron alloyed with chromium and other elements like nickel, molybdenum, and manganese to enhance their corrosion resistance and durability.

- Q: How do I prevent intergranular corrosion on stainless steel sheets?

- To prevent intergranular corrosion on stainless steel sheets, there are several measures you can take: 1. Choose the right stainless steel grade: Use stainless steel grades that are specifically resistant to intergranular corrosion, such as 304L, 316L, or 321. These grades have lower carbon content, which helps in minimizing the formation of chromium carbides at grain boundaries. 2. Heat treatment: After fabrication or welding, subject the stainless steel sheets to a solution annealing or post-weld heat treatment process. This heat treatment eliminates the chromium carbides that may have formed during welding or high-temperature processing, preventing intergranular corrosion. 3. Avoid exposure to high temperatures: Stainless steel sheets should not be exposed to temperatures between 450 to 850 degrees Celsius (842 to 1562 degrees Fahrenheit) for extended periods. If exposed, chromium carbides may form at the grain boundaries, making the stainless steel susceptible to intergranular corrosion. 4. Use proper welding techniques: When welding stainless steel sheets, use low heat input and minimize the time the material is exposed to high temperatures. This helps in reducing the formation of chromium carbides and preserves the corrosion resistance of the stainless steel. 5. Pickling and passivation: After fabrication or welding, ensure that the stainless steel sheets are properly pickled and passivated. Pickling removes any contaminants on the surface, while passivation forms a protective oxide layer that prevents intergranular corrosion. 6. Regular maintenance and cleaning: Keep the stainless steel sheets clean and free from contaminants that could potentially cause corrosion. Regularly clean the surfaces with mild detergents and avoid using harsh chemicals or abrasive materials that may damage the protective oxide layer. By following these preventative measures, you can significantly reduce the risk of intergranular corrosion on stainless steel sheets and maintain their corrosion resistance properties for a longer lifespan.

- Q: What type of welding rod is used for 304 stainless steel plate welding?

- The selection of reference electrode parent material, selection and composition of base metal electrode in the same or similar; owing to the great influence of carbon content on corrosion resistance of stainless steel, stainless steel weld metal carbon content is higher than that of base material.

- Q: What is the lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the environment in which they are used, and the maintenance practices followed. In general, stainless steel sheets have a long lifespan and are known for their durability and corrosion resistance. They are designed to withstand harsh conditions and are resistant to rust, stains, and other forms of degradation. Stainless steel sheets are typically made from austenitic stainless steel, which is known for its high levels of chromium and nickel. These elements provide excellent corrosion resistance and make stainless steel sheets highly resistant to rust and staining. As a result, stainless steel sheets can last for many years, often outlasting other materials such as aluminum or regular steel. The lifespan of stainless steel sheets can be further extended through proper care and maintenance. Regular cleaning and removal of any contaminants or debris can help prevent corrosion and maintain the appearance and performance of the sheets. Additionally, applying protective coatings or finishes can provide an extra layer of protection against corrosion and wear. While it is difficult to provide an exact lifespan for stainless steel sheets due to the variability of factors involved, with proper care and maintenance, they can easily last for several decades. In some cases, stainless steel sheets have been known to last for over a century. Therefore, investing in stainless steel sheets is often seen as a long-term solution, offering durability and cost-effectiveness over an extended period.

- Q: Can stainless steel sheets be used in medical equipment?

- Yes, stainless steel sheets can be used in medical equipment. Stainless steel is a popular choice for medical devices and equipment due to its excellent properties such as corrosion resistance, durability, and ease of cleaning. It is commonly used in surgical instruments, implants, hospital equipment, and laboratory tools. Stainless steel sheets are often used in the fabrication of medical equipment due to their versatility and ability to be molded into various shapes and sizes. Additionally, stainless steel is highly biocompatible, meaning it does not react with bodily tissues and is safe for use in medical applications. Overall, stainless steel sheets are a reliable and widely accepted material for medical equipment due to their hygienic properties and long-lasting performance.

- Q: Can stainless steel sheets be painted?

- Painting stainless steel sheets is indeed possible. However, it is crucial to adequately prepare the surface beforehand to ensure the paint adheres well and maintains its quality over time. Thoroughly cleaning and degreasing the stainless steel surface is essential, along with removing any existing rust or oxidation. To facilitate adhesion, it is advisable to use a primer specifically designed for metal surfaces, followed by a high-quality paint suitable for metal. Additionally, applying a clear coat or sealer is recommended to protect the paint finish. It is important to note that regular upkeep may be necessary to preserve the appearance of the painted stainless steel sheets, as the paint may chip or wear with time.

- Q: What are the different types of edge profiles for stainless steel sheets?

- Some different types of edge profiles for stainless steel sheets include square edge, round edge, beveled edge, and chamfered edge.

- Q: What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- Austenitic stainless steel (non-magnetic) inside the 201 material is the cheapest, the average price of 9000 yuan / ton, including tax, accounting for 7.93 of the proportion of formula: thickness * width * length * weight = weight * unit price = per price

- Q: How do you remove water spots from stainless steel sheets?

- Achieving water spot-free stainless steel sheets is simple with these steps: 1. Begin by thoroughly cleansing the surface using a mild dish soap and warm water solution. This will eliminate any dirt or grime that might contribute to the presence of water spots. 2. Rinse the sheets with fresh water and dry them completely using a soft cloth or towel. This is crucial to prevent the formation of new water spots during the cleaning procedure. 3. Subsequently, create a mixture of equal parts white vinegar and water. Immerse a clean cloth or sponge into the solution, ensuring to remove any excess liquid. 4. Gently rub the affected areas of the stainless steel sheets with the vinegar solution-soaked cloth or sponge. Make sure to follow the grain of the stainless steel in order to avoid scratching the surface. 5. Once the water spots have been rubbed, rinse the sheets with clean water and thoroughly dry them again using a soft cloth or towel. 6. If the water spots persist, you can attempt using a stainless steel cleaner or polish specifically formulated for eliminating stains and water spots. Follow the instructions provided with the cleaner and test it on a small, inconspicuous area beforehand to ensure it does not harm the stainless steel. Always remember to utilize soft materials and gentle cleaning techniques when dealing with stainless steel to prevent scratching or damaging the surface.

Send your message to us

301 cold rolled stainless steel plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords