CONCRETE PUMP Delivery pipe 3 M*DN125*6MMThickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

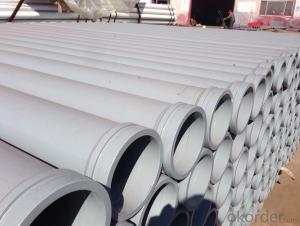

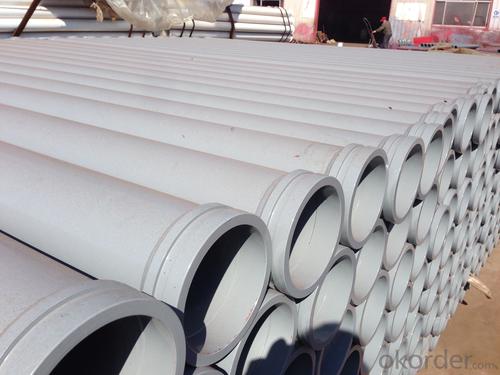

Production Name: CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness nd148mm Flange

Materials: ST 52

Concrete Pumping Capacity: about20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc)available.

Scope of Application of the Equipment

CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete pipe and its major components

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thicknessaccording to customers request?

A4: Yes, we can produce CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: What are the different types of concrete pump hopper pins?

- There are several types of concrete pump hopper pins, including snap pins, lynch pins, and clevis pins. These pins are used to secure the hopper to the pump and ensure it stays in place during operation.

- Q: What are the indicators of a faulty concrete pump seal?

- There are several indicators that can suggest a faulty concrete pump seal. These include: 1. Leakage: One of the most obvious signs of a faulty seal is leakage of concrete or water around the seal area. If you notice any fluid seeping out from the seal, it is a clear indication of a problem. 2. Reduced pumping efficiency: A faulty seal can result in reduced pumping efficiency. If you notice that the concrete pump is not delivering the expected amount of concrete or is struggling to pump the material, it could be due to a seal issue. 3. Increased noise and vibration: A faulty seal can cause increased noise and vibration during the operation of the concrete pump. Unusual sounds or excessive vibration can indicate that the seal is not functioning properly, and further inspection may be required. 4. Premature wear and tear: If the seal is faulty, it can lead to premature wear and tear of other components in the pump system. This can be observed through the degradation of other parts such as gaskets, bearings, or pistons. Regular inspections can help identify such issues. 5. Inconsistent pressure: A faulty seal can result in inconsistent pressure while pumping concrete. If you notice variations in the pressure output or irregular flow of concrete, it may be a sign of a seal problem. 6. Excessive heat: Another indicator of a faulty seal is the generation of excessive heat in the seal area. If the seal is not functioning properly, it can cause friction and heat buildup, which can be felt or observed by touch. It is important to address any indication of a faulty concrete pump seal promptly to prevent further damage to the pump system and ensure the safety and efficiency of the operation. Consulting a professional or contacting the manufacturer for guidance and repair is recommended in such cases.

- Q: Can concrete pump spare parts be painted or coated for increased durability?

- Yes, concrete pump spare parts can be painted or coated for increased durability. Painting or coating the spare parts can help protect them from corrosion, wear, and other forms of damage. By applying a layer of paint or coating, the spare parts can have improved resistance to harsh environmental conditions, chemicals, and moisture. Additionally, certain paints or coatings can offer additional benefits such as heat resistance or non-stick properties, which can further enhance the durability and performance of the spare parts. It is important to use appropriate paints or coatings that are specifically designed for the materials and conditions the spare parts will be exposed to, to ensure optimal adhesion and longevity.

- Q: Are there any specific maintenance procedures for concrete pump spare parts?

- Concrete pump spare parts require specific maintenance procedures to ensure effective functioning and longevity. It is crucial to regularly maintain them. Here are some key maintenance procedures for concrete pump spare parts: 1. Lubrication: Minimize friction and wear by regularly lubricating moving parts like pistons, cylinders, and valves. This helps maintain smooth operation and prevent premature failure. 2. Cleaning: Regularly clean spare parts to remove debris, dirt, or concrete buildup. Accumulated material can hinder performance and cause damage. Use appropriate cleaning agents and tools for thorough cleaning. 3. Inspection: Routinely inspect spare parts for signs of wear, damage, or deterioration. Check for cracks, leaks, loose connections, or abnormal functioning. Promptly detect issues for timely repairs or replacements. 4. Replacement: Immediately replace worn-out or damaged spare parts. Delaying replacements can lead to further damage and costly repairs. Follow the manufacturer's recommendations for part lifespan and replacement. 5. Calibration: Correctly calibrate spare parts to maintain optimum performance. Adjust pressure settings, flow rates, and other parameters according to manufacturer's guidelines. Regular calibration ensures accurate and efficient concrete pumping. 6. Storage: Properly store spare parts to prevent damage from environmental factors. Keep them in a clean, dry place away from direct sunlight or extreme temperatures. Follow any specific storage instructions from the manufacturer. 7. Training: Train operators and maintenance personnel on proper handling, maintenance, and repair of spare parts. This ensures correct procedures are followed, minimizing damage risk and maximizing equipment lifespan. Following these maintenance procedures will keep concrete pump spare parts in optimal condition, enhancing performance, reliability, and longevity.

- Q: How do I properly maintain and replace hydraulic pumps in concrete pump spare parts?

- Properly maintaining and replacing hydraulic pumps in concrete pump spare parts is crucial to ensure the smooth functioning and longevity of the equipment. Here are some steps to help you in this process: 1. Regular Inspections: Perform frequent visual inspections of the hydraulic pump to identify any signs of wear, leaks, or damage. Check for loose bolts, damaged seals, or excessive noise during operation. These inspections should be done before and after each use. 2. Follow Manufacturer's Guidelines: Refer to the manufacturer's guidelines and recommendations for maintenance and replacement of hydraulic pumps. They will provide specific instructions on the frequency of maintenance, lubrication, and replacement intervals. 3. Lubrication: Proper lubrication is essential for the smooth operation of hydraulic pumps. Check the oil levels regularly and top up if necessary. Use the recommended oil or hydraulic fluid as specified by the manufacturer. Follow the guidelines for the frequency of oil changes. 4. Regular Cleaning: Keep the hydraulic pump and its components clean from debris, dust, and dirt. Use a clean cloth or compressed air to remove any contaminants that may have accumulated. This will help prevent damage and reduce the risk of clogs or blockages. 5. Replace Worn Parts: Over time, certain components of the hydraulic pump may wear out and require replacement. Keep a stock of spare parts, including seals, gaskets, and filters, to be able to promptly replace any worn or damaged components. 6. Seek Professional Assistance: If you are unsure about any aspect of maintaining or replacing hydraulic pumps, it is always advisable to seek the assistance of a professional technician or the manufacturer. They have the expertise and knowledge to guide you through the process and ensure the best possible maintenance and replacement practices. Remember, regular maintenance and timely replacement of hydraulic pumps in concrete pump spare parts will not only extend the lifespan of the equipment but also ensure safe and efficient operation on construction sites.

- Q: How do I properly maintain and replace hydraulic filters in concrete pump spare parts?

- To properly maintain and replace hydraulic filters in concrete pump spare parts, follow these steps: 1. Regularly inspect the hydraulic filters for any signs of damage, clogs, or excessive dirt accumulation. 2. If the filter is damaged or excessively dirty, replace it immediately to ensure the proper functioning of the hydraulic system. 3. Before replacing the filter, ensure that the hydraulic system is depressurized to avoid any accidents. 4. Carefully remove the old filter and dispose of it properly. 5. Clean the filter housing thoroughly to remove any debris or contaminants. 6. Install the new hydraulic filter, ensuring that it is properly seated and secured in place. 7. Double-check that all connections and fittings are tight to prevent any leakage. 8. Once the new filter is in place, refill the hydraulic system with the recommended hydraulic fluid. 9. After replacing the filter, run the concrete pump and observe for any abnormal sounds, leaks, or pressure fluctuations. 10. Maintain a regular filter replacement schedule based on the manufacturer's recommendations to ensure optimal performance and prevent potential damage to the hydraulic system.

- Q: How can a faulty battery affect the operation of the pump?

- A faulty battery can significantly affect the operation of a pump. Firstly, a faulty battery may not provide enough power to the pump, resulting in slow or weak pumping action. This can impact the pump's ability to generate the necessary pressure or flow rate, leading to inefficient or ineffective operation. Additionally, a faulty battery may cause intermittent power supply to the pump. This can result in inconsistent pumping action, with the pump starting and stopping sporadically. Such interruptions can create inefficiencies, reduce the pump's performance, and potentially cause damage to the equipment or system being operated. Furthermore, a faulty battery may not hold a charge for an extended period. This can limit the pump's runtime, requiring frequent recharging or replacement of the battery. In scenarios where a pump is needed for continuous or prolonged usage, a faulty battery can disrupt operations, leading to downtime and reduced productivity. Moreover, a faulty battery can also impact the overall lifespan of the pump. If the battery does not provide the necessary power consistently, the pump may experience strain or excessive wear, potentially shortening its operational life. Overall, a faulty battery can have various adverse effects on the operation of a pump, including reduced performance, inconsistent pumping action, limited runtime, potential damage, and decreased equipment lifespan. Regular maintenance and timely replacement of faulty batteries are crucial to ensure optimal pump performance and longevity.

- Q: In general, how much concrete will be transported per hour for the concrete pump and the pump?

- Tank car replacement, reversing the car by about 5-8 minutes

- Q: How do I properly maintain and replace concrete delivery pipes in concrete pump spare parts?

- Properly maintaining and replacing concrete delivery pipes in concrete pump spare parts is crucial to ensure the efficient and safe operation of the concrete pump. Here are some steps you can follow: 1. Regular Inspection: Regularly inspect the concrete delivery pipes for any signs of wear and tear, cracks, or damage. Look for any leaks or blockages that may affect the concrete flow. Identify any weak points that may require replacement. 2. Cleaning: Clean the concrete delivery pipes thoroughly after each use. Use water and a high-pressure hose to remove any concrete residue or build-up. This will prevent clogging and maintain the smooth flow of concrete. 3. Lubrication: Apply a suitable lubricant to the inner surface of the pipes to reduce friction and prevent concrete from sticking. This will help prolong the life of the pipes and ensure smooth concrete flow. 4. Replace Worn-out Parts: Monitor the condition of the delivery pipes and replace any worn-out or damaged parts promptly. Over time, the pipes may become corroded or develop cracks, affecting their performance. Replace these parts with high-quality spare parts to ensure the best results. 5. Proper Handling: Handle the concrete delivery pipes with care to avoid any unnecessary damage. Avoid dropping or mishandling the pipes during transportation or storage. Protect them from extreme weather conditions and store them in a dry and secure place. 6. Training and Safety: Ensure that the personnel operating the concrete pump are well-trained in handling and maintaining the equipment. Educate them about the importance of regular inspections, cleaning, and replacement of parts. Emphasize safety protocols to prevent accidents and ensure the longevity of the concrete delivery pipes. By following these steps, you can properly maintain and replace concrete delivery pipes in concrete pump spare parts, ensuring the efficient and safe operation of your concrete pump. Regular maintenance and prompt replacement of worn-out parts will help extend the life of the pipes and ensure the smooth flow of concrete during construction projects.

- Q: What are the common causes of overheating in concrete pump spare parts?

- Concrete pump spare parts can overheat due to various common causes. One primary reason is improper lubrication, which results in increased friction and overheating of the pump's moving parts like bearings and pistons. To prevent this, it is essential to regularly inspect and maintain the lubrication system to ensure smooth operation. Excessive use or continuous operation without breaks is another common cause of overheating. Concrete pumps have a designated workload, and surpassing it or neglecting proper rest periods can lead to overheating of the components. To avoid this, it is crucial to adhere to recommended operating guidelines and periodically allow the pump to cool down. Additionally, overheating can occur due to clogged or blocked cooling systems. The cooling system in a concrete pump regulates temperature by circulating coolant around vital parts. If the system gets clogged or the coolant level is insufficient, overheating may occur. Regular inspection, cleaning, and maintaining appropriate coolant levels can prevent this issue. Inadequate ventilation is also a common cause of overheating. Concrete pumps generate substantial heat during operation, and if the surrounding environment lacks proper airflow, the heat cannot dissipate effectively. This can lead to overheating of spare parts. To avoid this, it is important to operate the pump in well-ventilated areas or utilize additional cooling measures like fans or air conditioning. Lastly, a malfunctioning or damaged pump component can cause overheating. When a part such as the motor or hydraulic system does not function correctly, it places additional strain on other components, resulting in overheating. Regular maintenance and inspection of the pump's components can help identify and address any potential issues before they lead to overheating. In conclusion, preventing overheating in concrete pump spare parts requires proper lubrication, adherence to operating guidelines, maintenance of cooling systems, ensuring adequate ventilation, and regular component inspection.

Send your message to us

CONCRETE PUMP Delivery pipe 3 M*DN125*6MMThickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords