Concrete Pump Delivery Pipe DN125*4.5mm*3m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Delivery Pipe DN125*4.5mm*3m

1. Structure of Concrete Pump Delivery Pipe DN125*4.5mm*3m:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

2. Main Features of Concrete Pump Delivery Pipe DN125*4.5mm*3m:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

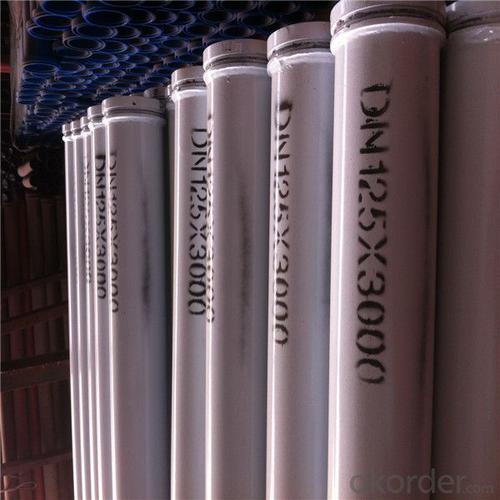

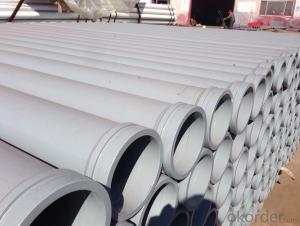

3. Concrete Pump Delivery Pipe DN125*4.5mm*3m Images

4. Concrete Pump Delivery Pipe DN125*4.5mm*3m Specification

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

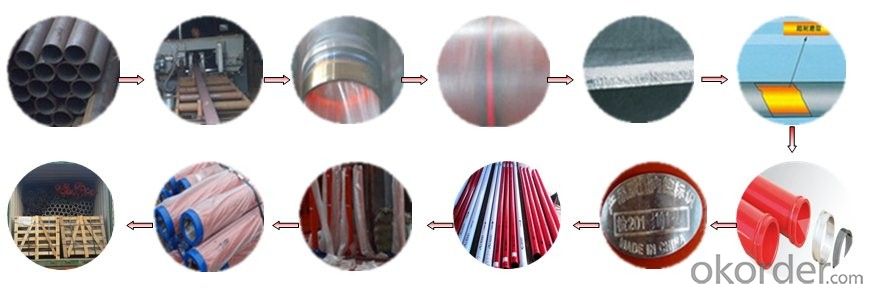

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts. These guidelines typically include ensuring proper alignment, securely fastening the filter/strainer, and following manufacturer instructions for installation. Additionally, regular maintenance and inspection of the filters/strainers is recommended to ensure optimal performance and prevent potential issues.

- Q: How do I determine the correct temperature ratings for concrete pump spare parts?

- To determine the correct temperature ratings for concrete pump spare parts, you need to consider the specific requirements and specifications of your concrete pump system. Here are some steps to help you in this process: 1. Consult the manufacturer's documentation: Start by reviewing the technical specifications provided by the manufacturer of your concrete pump system. The manufacturer should provide temperature ratings for different components and spare parts. Look for information on temperature limits, recommended operating temperature ranges, and any specific guidelines or restrictions related to temperature. 2. Identify critical components: Identify the key components of your concrete pump system that may be affected by temperature, such as hoses, seals, gaskets, valves, and electrical components. These components may have different temperature ratings depending on the materials used and their specific design. 3. Consider application conditions: Assess the operating conditions of your concrete pump system to determine the potential temperature extremes it may encounter. Factors such as ambient temperature, concrete mix temperature, and the presence of external heat sources (such as hot weather or nearby equipment) can affect the temperature of the system and its spare parts. 4. Check compatibility: Ensure that the spare parts you are considering have compatibility with the specific temperature range of your concrete pump system. Some components may have different ratings based on factors like chemical compatibility, thermal expansion, and resistance to heat transfer. 5. Seek expert advice: If you are uncertain about the temperature ratings or need further clarification, it is advisable to consult with professionals or experts in the field of concrete pump systems. They can provide specific recommendations based on their knowledge and experience. By following these steps and considering the manufacturer's guidelines and expert advice, you can determine the correct temperature ratings for concrete pump spare parts, ensuring the safe and efficient operation of your system.

- Q: What are the different types of concrete pump hopper vibrators?

- There are several different types of concrete pump hopper vibrators available on the market. These vibrators are designed to help keep the concrete flowing smoothly through the hopper and into the pumping system. 1. Electric Vibrators: These are the most common type of hopper vibrators and are powered by electricity. They are typically attached to the side of the hopper and use an electric motor to create vibrations that help move the concrete. 2. Pneumatic Vibrators: These vibrators are powered by compressed air and are often used in situations where electricity is not readily available. They work by using air pressure to create vibrations that help keep the concrete flowing. 3. Hydraulic Vibrators: These vibrators are powered by hydraulic fluid and are often used in larger concrete pumping systems. They can be more powerful than electric or pneumatic vibrators and are often used in heavy-duty applications. 4. Rotary Vibrators: These vibrators work by spinning an eccentric weight, creating vibrations that help move the concrete. They are often used in situations where a high frequency of vibration is required. 5. Turbine Vibrators: These vibrators use a turbine mechanism to create vibrations. They are often used in situations where a low frequency of vibration is needed. 6. Ball Vibrators: These vibrators use a ball inside a housing to create vibrations. They are often used in smaller concrete pumping systems and can be easily mounted to the hopper. Overall, the type of concrete pump hopper vibrator that is best for a particular application will depend on factors such as the size and type of the concrete pumping system, the desired frequency and intensity of vibration, and the availability of power sources.

- Q: What are the signs of a malfunctioning concrete pump control valve?

- Some signs of a malfunctioning concrete pump control valve may include erratic or inconsistent flow of concrete, difficulty in controlling the pump speed, leaking or dripping of hydraulic fluid, unusual noises or vibrations coming from the valve, and unresponsive or delayed response to control inputs.

- Q: How does a concrete pump S valve function?

- A concrete pump S valve functions by controlling the flow of concrete from the hopper to the discharge outlet. The S valve is a crucial component in the concrete pumping system as it allows for the precise and efficient delivery of concrete to the desired location. The S valve consists of two separate valves, one on each side, that are connected by a central shaft. These valves are shaped like an "S", hence the name. Each valve has a concrete outlet and a hydraulic cylinder that controls its movement. When the concrete pump is activated, the hydraulic system applies pressure to the cylinders, causing them to push the valves open. As the valves open, concrete is allowed to flow from the hopper into the pump's cylinder. Once the concrete is inside the cylinder, the hydraulic system reverses the pressure on the cylinders, causing them to retract. This movement pulls the valves closed, sealing off the cylinder and preventing any backflow of concrete. As the cylinder retracts, it also pushes the concrete inside towards the discharge outlet. The pressure created by the retraction of the cylinder forces the concrete through the outlet pipe, which leads to the desired location for pouring. The S valve's design allows for a smooth and continuous flow of concrete, without any interruption or blockages. It also provides a high level of control over the concrete placement, allowing operators to adjust the flow rate and direction as needed. Overall, the concrete pump S valve is responsible for regulating the flow of concrete, ensuring its efficient and precise delivery to the desired location. Its reliable and effective functioning is vital for successful concrete pumping operations.

- Q: What are the different sizes of concrete pump pipes available?

- The sizes of concrete pump pipes available vary depending on the specific needs and requirements of the construction project. Typically, concrete pump pipes come in sizes ranging from 2 inches to 6 inches in diameter. The most commonly used sizes are 2 inches, 3 inches, 4 inches, and 5 inches. The choice of pipe size depends on factors such as the volume and pressure of the concrete being pumped, the distance the concrete needs to travel, and the type of equipment being used. Smaller diameter pipes are suitable for shorter distances and lower volumes of concrete, while larger diameter pipes are used for longer distances and higher volumes. It is important to select the appropriate pipe size to ensure efficient and safe concrete pumping. Using the correct size of pipe helps to minimize pressure loss, maintain a consistent flow rate, and prevent blockages or clogs in the system. Consulting with a concrete pumping professional or engineer is recommended to determine the most suitable pipe size for a specific construction project.

- Q: How often should concrete pump hydraulic motors be inspected and replaced?

- Concrete pump hydraulic motors should be inspected regularly, ideally every 500 to 1000 hours of operation, to ensure they are in good working condition. However, the frequency of replacement depends on various factors such as usage intensity, maintenance practices, and the quality of the motor. Generally, hydraulic motors can last for several years if properly maintained, but if any signs of wear, leakage, or reduced performance are observed, it is recommended to replace them promptly to prevent potential breakdowns or accidents.

- Q: Why would the plugging concrete pump pipe

- Pump operator in pumping construction should concentrate, always pay attention to pumping pressure meter readings, once found that the pressure gauge reading suddenly increased, should immediately anti pump 2-3 stroke, and then pump, pipe can be excluded

- Q: What is the function of a concrete pump hydraulic accumulator?

- A concrete pump hydraulic accumulator serves a crucial function in the operation of a concrete pump. Its main purpose is to store and release hydraulic energy, which helps in maintaining a constant and smooth flow of concrete during pumping operations. The hydraulic accumulator acts as a pressure storage tank that is connected to the hydraulic system of the concrete pump. When the pump is not in operation, the accumulator stores pressurized hydraulic fluid. This stored energy can be released when required, such as during the pumping process, providing an additional power source to supplement the main hydraulic system. During concrete pumping, the accumulator assists in maintaining a consistent flow of concrete by compensating for pressure fluctuations in the hydraulic system. It serves as a buffer, absorbing any excess pressure and releasing it back into the system when needed. This helps in preventing pressure spikes or drops, which could otherwise lead to irregular concrete flow or even damage to the pump. Furthermore, the hydraulic accumulator also plays a role in reducing energy consumption and enhancing the overall efficiency of the concrete pump. By storing and reusing energy, it minimizes the need for constant power supply from the main hydraulic system, thereby reducing the load on the pump's engine and improving fuel efficiency. Overall, the function of a concrete pump hydraulic accumulator is to store and release hydraulic energy, ensuring a consistent and smooth flow of concrete during pumping operations, while also contributing to energy efficiency and protecting the pump from potential damage.

- Q: Can concrete pump spare parts be customized according to specific requirements?

- Yes, concrete pump spare parts can be customized according to specific requirements. Customization allows for the adaptation of parts to meet specific needs such as size, shape, material, or functionality. This enables better compatibility and enhances the efficiency and performance of concrete pumps.

Send your message to us

Concrete Pump Delivery Pipe DN125*4.5mm*3m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords