Concrete Pump Truck Parts Bend ZX-HD DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery bend connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. Hydraulic tester & artificial detection./ Uniform baking finish. Seaworthy packing or as customers’ request.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market.

5. OEM service available.

6. Fitting to PUTZMEISTER, SCHWING Sany, Zoomlion concrete pumps

Product Specifications:

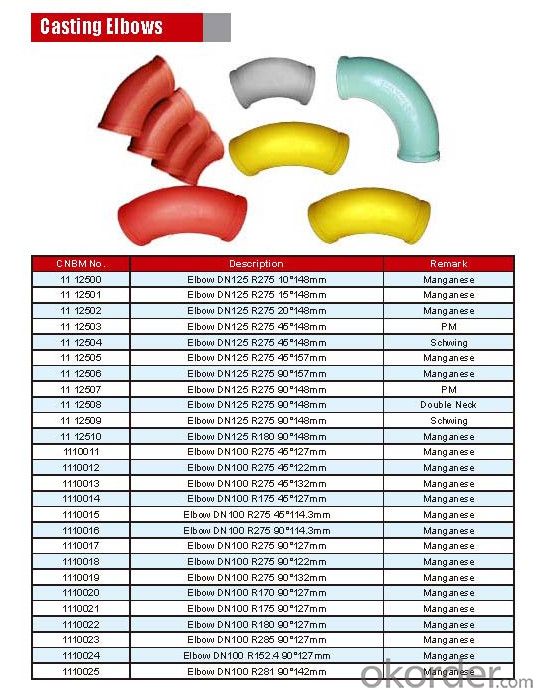

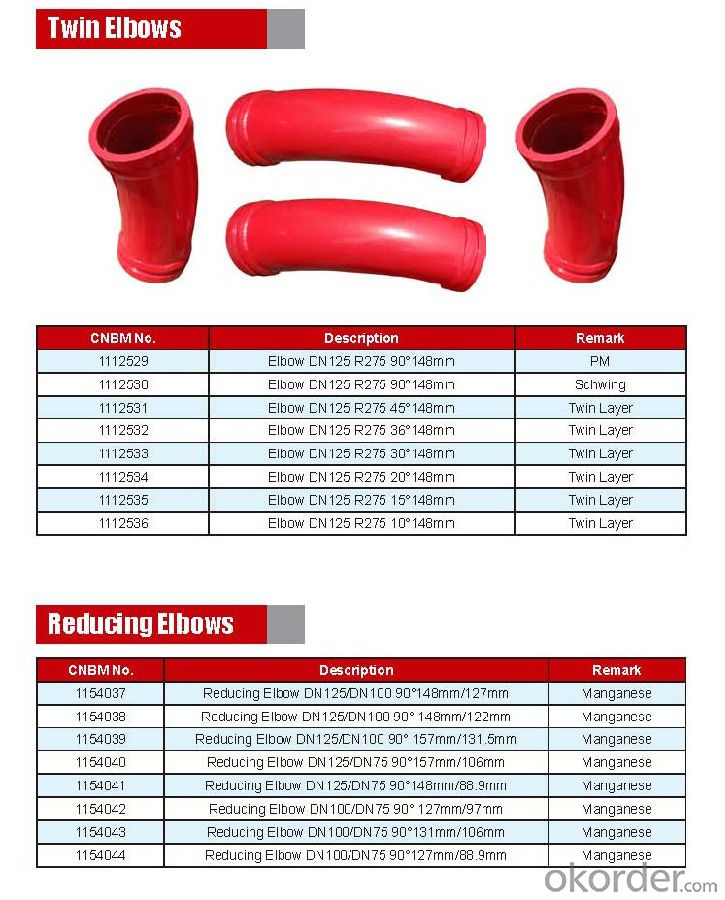

Technical: Casting

Radius: 500mm

Degree: 45

Material: Mn13-4

Characteristics: According to our technology, the casting bends also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your bends could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: How can a faulty filter affect the pumping process?

- A faulty filter can significantly affect the pumping process in several ways. Firstly, a faulty filter may become clogged or blocked, hindering the flow of fluid through the pump. This can result in reduced efficiency and increased energy consumption as the pump has to work harder to overcome the resistance caused by the clogged filter. The decreased flow rate can also lead to longer pumping times, which can be problematic in time-sensitive applications. Secondly, a faulty filter may fail to effectively remove impurities or contaminants from the fluid being pumped. This can be particularly problematic in industries where maintaining the purity or cleanliness of the fluid is crucial, such as in pharmaceutical or food processing applications. The presence of contaminants can compromise the quality of the final product or damage equipment downstream from the pump. Furthermore, a faulty filter can lead to increased maintenance and repair costs. If the filter is not functioning properly, it may allow larger particles or debris to pass through, which can cause damage to the pump components. This can result in increased wear and tear, decreased lifespan of the pump, and the need for more frequent repairs or replacements. Lastly, a faulty filter can also pose a risk to the overall system and its components. If the filter fails completely, it may allow foreign objects or particles to enter the pump, leading to potential blockages, damage to internal components, or even complete failure of the pump. This can result in costly downtime, loss of production, and the need for emergency repairs or replacements. In summary, a faulty filter can have detrimental effects on the pumping process, including decreased efficiency, compromised fluid quality, increased maintenance costs, and potential damage to the pump and system components. Regular inspection, maintenance, and timely replacement of filters are essential to ensure smooth and reliable operation of pumps in various industries.

- Q: How often should hopper screens be cleaned or replaced?

- Hopper screens should be cleaned or replaced on a regular basis, typically every 3 to 6 months, depending on usage and the type of materials being processed. Regular cleaning of the hopper screens is essential to maintain optimal performance and prevent clogging or blockages. If the screens become excessively dirty or damaged, they should be replaced immediately to ensure uninterrupted flow of materials and prevent any potential damage to the equipment. Regular maintenance and inspections of the hopper screens will help to prolong their lifespan and ensure smooth operation of the entire system.

- Q: How to operate the concrete pump?

- The size of sand and gravel, cement mark and mixture ratio should meet the requirement of the mechanical performance of the pump according to the specifications of the factory

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Concrete pump spare parts require specific cleaning and maintenance procedures to ensure their proper functioning. Regular cleaning is crucial to remove any concrete buildup or residue from the parts. This can be achieved by either using a high-pressure water jet or immersing the parts in a cleaning solution specifically designed for concrete. It is vital to adhere to the manufacturer's instructions when using cleaning agents to guarantee the safety and effectiveness of the cleaning process. Furthermore, routine maintenance is necessary to extend the lifespan of the concrete pump spare parts and ensure their optimal performance. This involves inspecting the parts for any signs of wear, such as cracks or corrosion, and replacing them if needed. It is also important to lubricate the moving parts, like bearings or pistons, according to the manufacturer's recommendations. It is worth noting that different concrete pump spare parts may have unique cleaning and maintenance requirements. Therefore, it is advisable to consult the manufacturer's guidelines or seek guidance from a qualified technician to determine the appropriate procedures for each specific part.

- Q: What are the skills of concrete pump?

- According to the characteristics of the construction site and concrete pouring plan piping, piping design to check the level of the pipeline, conversion distance and the concrete pump pumping distance to adapt

- Q: Are there any specific maintenance procedures for concrete pump spare parts?

- Concrete pump spare parts require specific maintenance procedures to ensure effective functioning and longevity. It is crucial to regularly maintain them. Here are some key maintenance procedures for concrete pump spare parts: 1. Lubrication: Minimize friction and wear by regularly lubricating moving parts like pistons, cylinders, and valves. This helps maintain smooth operation and prevent premature failure. 2. Cleaning: Regularly clean spare parts to remove debris, dirt, or concrete buildup. Accumulated material can hinder performance and cause damage. Use appropriate cleaning agents and tools for thorough cleaning. 3. Inspection: Routinely inspect spare parts for signs of wear, damage, or deterioration. Check for cracks, leaks, loose connections, or abnormal functioning. Promptly detect issues for timely repairs or replacements. 4. Replacement: Immediately replace worn-out or damaged spare parts. Delaying replacements can lead to further damage and costly repairs. Follow the manufacturer's recommendations for part lifespan and replacement. 5. Calibration: Correctly calibrate spare parts to maintain optimum performance. Adjust pressure settings, flow rates, and other parameters according to manufacturer's guidelines. Regular calibration ensures accurate and efficient concrete pumping. 6. Storage: Properly store spare parts to prevent damage from environmental factors. Keep them in a clean, dry place away from direct sunlight or extreme temperatures. Follow any specific storage instructions from the manufacturer. 7. Training: Train operators and maintenance personnel on proper handling, maintenance, and repair of spare parts. This ensures correct procedures are followed, minimizing damage risk and maximizing equipment lifespan. Following these maintenance procedures will keep concrete pump spare parts in optimal condition, enhancing performance, reliability, and longevity.

- Q: What is the washing process of the concrete pump pipe?

- Connect the reducing pipe and close the discharge door. Pour water directly into the hopper.

- Q: How do I maintain and clean concrete pump spare parts?

- To ensure the long life and smooth operation of concrete pump spare parts, it is crucial to maintain and clean them. Follow these steps to accomplish this: 1. Conduct Routine Inspections: Begin by carefully examining the spare parts for signs of wear, cracks, or damage. This step is essential for identifying potential issues that require immediate attention. 2. Apply Lubrication: To minimize friction and prevent seizing, apply lubricant to moving parts like bearings, pistons, and cylinders. 3. Thoroughly Clean: Employ a high-pressure washer or hose to thoroughly clean the spare parts. Eliminate any accumulated dirt, debris, or concrete residue, paying particular attention to hard-to-reach areas. 4. Prevent Rust: Guard metal parts against corrosion by applying a rust preventive coating. This step is especially important if the spare parts are exposed to moisture or inclement weather conditions. 5. Proper Storage: Store the spare parts in a clean and dry location to shield them from moisture, dust, and other contaminants. Avoid directly stacking them on the ground to prevent damage. 6. Regular Maintenance: Establish a maintenance schedule and adhere to it. Adhere to the manufacturer's guidelines for routine tasks such as replacing filters, checking oil levels, and inspecting seals. Regular maintenance aids in the detection of potential issues before they escalate into major problems. 7. Seek Professional Assistance: If you are uncertain about how to maintain or clean specific spare parts, it is advisable to seek professional assistance. Concrete pump spare parts are intricate and necessitate expert handling. Remember, proper maintenance and regular cleaning of concrete pump spare parts not only prolong their lifespan but also enhance the overall performance and efficiency of your concrete pump.

- Q: What are some common issues with concrete pump hoses and how can they be prevented?

- Concrete pump hoses can encounter various problems such as blockages, leaks, and premature wear. To avoid these issues, it is essential to adhere to proper maintenance and usage practices. 1. Blockages: Blockages can occur when concrete or debris hardens inside the hoses. Thoroughly cleaning the hoses after each use is crucial to prevent blockages. Flushing the hoses with water or using a cleaning sponge ball effectively removes any residue or build-up. Additionally, using the correct size and length of hose for the job reduces the risk of blockages. 2. Leaks: Leaks may result from wear and tear, improper connections, or hose damage. Regularly inspecting the hoses is vital to detect any signs of leakage. Any leaks detected should be promptly repaired or replaced. Properly connecting and securing the hose fittings also helps prevent leaks. 3. Premature Wear: Over time, concrete pump hoses can wear out due to factors such as abrasion, bending, and exposure to harsh chemicals. Handling the hoses with care and avoiding dragging them on rough surfaces is important to prevent premature wear. Using protective sleeves or guards provides additional protection against abrasion. Regularly inspecting the hoses for signs of wear and replacing them when necessary is essential. 4. Storage Practices: Improper storage of concrete pump hoses can cause damage and reduce their lifespan. Storing the hoses in a clean and dry environment away from direct sunlight and extreme temperatures is recommended. Properly coiling the hoses and avoiding sharp bends or kinks helps maintain their integrity. 5. Pressure Management: Exceeding the recommended pressure limits can result in hose bursts or failures. Ensuring that the concrete pump operates within the specified pressure range is crucial. Regularly inspecting the pressure gauges and monitoring the pumping process aids in preventing over-pressurization. By adhering to these preventive measures, conducting regular inspections, and performing necessary maintenance, the common issues associated with concrete pump hoses can be minimized. This, in turn, leads to improved performance and increased longevity of the hoses.

- Q: How does a concrete pump clamp work?

- An integral part of a concrete pump is the concrete pump clamp, which is utilized to securely fasten and stabilize the concrete delivery pipeline. Its function is to firmly grasp the pipeline, eliminating any potential movement or leakage throughout the concrete pumping procedure. Typically comprised of two primary components, the concrete pump clamp consists of the clamp body and the wedge. The clamp body, constructed from durable steel, possesses a curved structure tailored to the pipeline's shape. Equipped with bolts or knobs, it can be tightened or loosened to attach the clamp to the pipeline. In contrast, the wedge is a metal piece that is inserted into the clamp body. Its purpose is to apply pressure to the pipeline when the clamp is tightened. By manipulating the bolts or knobs, the wedge is pushed deeper into the clamp body, effectively squeezing the pipeline and establishing a secure grip. The secure grip achieved by the concrete pump clamp is essential as it guarantees a seamless and uninterrupted flow of concrete without any leaks or disruptions. It upholds a consistent and steady movement of concrete from the pump to the desired destination. Furthermore, the clamp contributes to the stability of the pipeline, preventing any shifting or displacement during the pumping process. In summary, the concrete pump clamp assumes a crucial role in the efficient and safe operation of a concrete pump. It ensures the secure placement of the concrete delivery pipeline, facilitating a smooth and uninterrupted concrete pumping process.

Send your message to us

Concrete Pump Truck Parts Bend ZX-HD DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords