PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

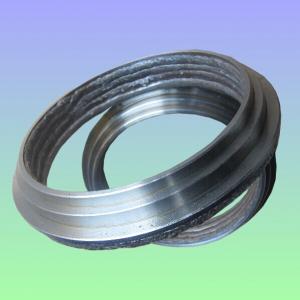

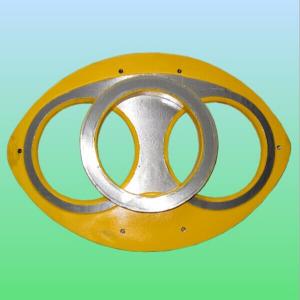

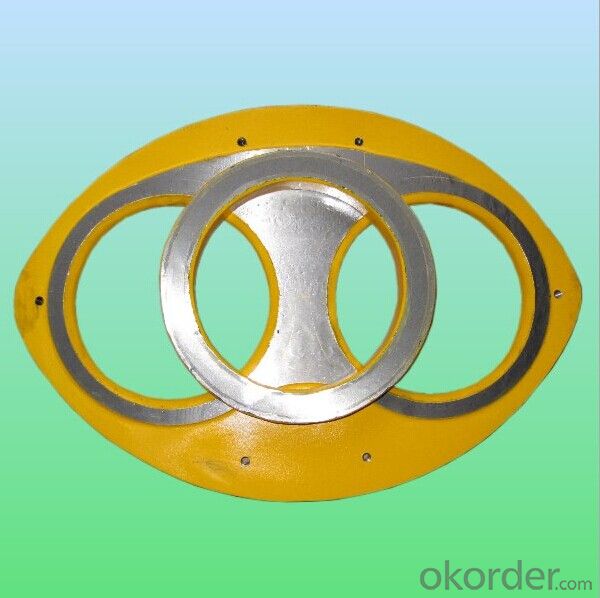

Product Name: PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Putzmeister concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide according to customers request?

A4: Yes, we can produce PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: What are the specifications for concrete delivery pumps?

- The staff shall not climb or ride on the pipeline, and should be absolutely avoided when working at high altitude

- Q: Are there any specific tools required for replacing concrete pump spare parts?

- Yes, there are specific tools required for replacing concrete pump spare parts. These tools typically include a wrench set, pliers, screwdrivers, hammer, hydraulic jack, grease gun, and a welding machine. Additionally, specialized tools such as a concrete pump cleaning ball and pipe wrench may be required depending on the specific spare part being replaced.

- Q: What is the purpose of a concrete pump agitator motor?

- The objective of a concrete pump agitator motor is to guarantee the uniformity and excellence of the concrete mixture being transported. Its role involves ensuring that the concrete mixture remains well-blended and prevents any settling or separation during the pumping procedure. The agitator motor aids in maintaining a consistent and homogeneous mixture, which is essential for achieving sturdy and long-lasting concrete structures. Through continuous agitation of the concrete inside the pump, the motor assists in averting any obstruction or congestion that may potentially disrupt the pumping operation. In general, the purpose of a concrete pump agitator motor is to optimize the efficiency and effectiveness of the concrete pumping process, ultimately leading to improved construction outcomes.

- Q: How often should I replace concrete pump spare parts?

- The frequency of replacing concrete pump spare parts depends on several factors such as the quality of the parts, the intensity of usage, and the maintenance practices. However, as a general guideline, it is recommended to inspect and replace worn or damaged concrete pump spare parts on a regular basis, typically every 6 to 12 months, to ensure optimal performance and avoid potential breakdowns or safety hazards.

- Q: Are there any specific maintenance procedures for concrete pump spare parts?

- Yes, there are specific maintenance procedures for concrete pump spare parts. Regular maintenance is crucial to ensure the effective functioning and longevity of the equipment. Here are some key maintenance procedures for concrete pump spare parts: 1. Lubrication: Regularly lubricate all moving parts such as pistons, cylinders, and valves to minimize friction and wear. This helps to maintain smooth operation and prevent premature failure. 2. Cleaning: Clean the spare parts regularly to remove any debris, dirt, or concrete buildup. Accumulated material can hinder the performance and cause damage to the parts. Use appropriate cleaning agents and tools to ensure a thorough cleaning. 3. Inspection: Conduct routine inspections of all spare parts to identify any signs of wear, damage, or deterioration. Check for cracks, leaks, loose connections, or any abnormal functioning. Timely detection of issues allows for prompt repairs or replacements. 4. Replacement: Replace worn-out or damaged concrete pump spare parts as soon as necessary. Delaying replacements can lead to further damage and potentially expensive repairs. Follow the manufacturer's recommendations for the lifespan of specific parts and replace them accordingly. 5. Calibration: Ensure that all spare parts are correctly calibrated to maintain optimum performance. This includes adjusting pressure settings, flow rates, and other parameters according to the manufacturer's guidelines. Regular calibration helps to ensure accurate and efficient concrete pumping. 6. Storage: Properly store spare parts when not in use to prevent damage from environmental factors. Keep them in a clean and dry place, away from direct sunlight or extreme temperatures. Additionally, follow any specific storage instructions provided by the manufacturer. 7. Training: Train operators and maintenance personnel on the proper handling, maintenance, and repair of concrete pump spare parts. This will ensure that the procedures are followed correctly, minimizing the risk of damage and maximizing the lifespan of the equipment. By following these specific maintenance procedures, concrete pump spare parts can be kept in optimal condition, enhancing their performance, reliability, and longevity.

- Q: How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- Hopper grate pin retainers in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure their proper functioning and prevent any potential issues. However, the frequency of inspections may vary depending on the specific conditions of use and the manufacturer's recommendations. During these inspections, it is essential to check for any signs of wear, damage, or corrosion on the hopper grate pin retainers. If any of these issues are detected, immediate replacement is necessary to maintain the efficiency and safety of the concrete pump. Additionally, it is crucial to adhere to the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may recommend replacing them after a certain number of operating hours, while others may suggest replacement based on the visual condition during inspections. Regular inspections and timely replacement of hopper grate pin retainers are crucial to prevent potential malfunctions or accidents during concrete pumping operations. It is always recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines regarding the inspection and replacement intervals for hopper grate pin retainers.

- Q: What are the different types of concrete pump hopper agitator motors?

- There are generally two types of concrete pump hopper agitator motors: electric motors and hydraulic motors. Electric motors are powered by electricity and are commonly used in smaller and portable concrete pumps. Hydraulic motors, on the other hand, are driven by hydraulic power generated by the concrete pump itself and are typically used in larger and stationary concrete pumps.

- Q: How do I troubleshoot common problems with concrete pump spare parts?

- To troubleshoot common issues with concrete pump spare parts, it is important to approach the task systematically. Here are a few steps that can assist you in identifying and resolving problems: 1. Start by observing the symptoms and pinpointing the specific problem you are facing. These may include leaks, reduced pumping efficiency, abnormal noise, or power failure. 2. Examine the pump's hoses, pipes, and valves for any clogs or blockages that may impede the flow of concrete. Remove any debris or obstructions you come across. 3. Inspect the wear parts, such as the pump's pistons, seals, or gaskets, for signs of wear and tear, cracks, or damage. Replace any worn-out components when necessary. 4. Check for any air leaks that may affect the pump's performance. Inspect the fittings, connections, and seals for signs of air leakage. Tighten loose fittings or replace faulty seals as required. 5. Ensure that the lubrication system is functioning properly. Lack of lubrication can cause friction and damage to the pump's moving parts. Add lubricant if needed. 6. Verify the electrical connections if you encounter power failure or electrical problems. Look for loose or damaged wires and connections. Repair or replace any faulty components. 7. Consult the manufacturer's manual for valuable troubleshooting information specific to your concrete pump spare parts. Refer to the manual to understand the recommended maintenance procedures and troubleshooting steps. 8. If you are unable to identify or resolve the issue on your own, it is advisable to seek professional assistance. Contact a qualified technician or the manufacturer's customer support for further guidance and support. Always remember that regular maintenance and proper usage of concrete pump spare parts can help minimize the occurrence of problems.

- Q: How can a faulty lubrication system affect the pump's performance?

- A faulty lubrication system can significantly affect the pump's performance in several ways. Firstly, a lubrication system is responsible for providing a thin film of lubricant between moving parts of the pump, reducing friction and wear. If the lubrication system is faulty or inadequate, it can result in increased friction between components, leading to excessive heat generation and accelerated wear and tear. This can ultimately reduce the efficiency and lifespan of the pump. Secondly, a faulty lubrication system can cause inadequate lubrication to critical components, such as bearings and seals. Insufficient lubrication can lead to increased friction, heat, and ultimately, premature failure of these components. This can result in increased downtime, costly repairs, and potential damage to other parts of the pump. Furthermore, a faulty lubrication system can also result in the contamination of the lubricant. Contaminants such as dirt, debris, or moisture can enter the system due to leaks or improper maintenance. These contaminants can cause abrasive damage to the pump's internal components, leading to reduced efficiency, increased wear, and potential failure. Lastly, a faulty lubrication system can also impact the pump's overall performance and energy consumption. Insufficient lubrication can increase the power requirements of the pump as it works harder to overcome friction and resistance. This can result in higher energy consumption and increased operating costs. In conclusion, a faulty lubrication system can severely impact the pump's performance by causing increased friction, accelerated wear and tear, premature failure of critical components, contamination of the lubricant, and increased energy consumption. Regular maintenance and proper lubrication are crucial to ensure the pump operates at its optimal level and to extend its lifespan.

- Q: Can concrete pump spare parts be coated with corrosion inhibitors for long-term storage?

- Concrete pump spare parts have the capability to be coated with corrosion inhibitors in order to ensure long-term storage. Corrosion inhibitors, which are chemicals, can be applied onto metal surfaces to either prevent or minimize the corrosion process. By administering a coating of corrosion inhibitor onto concrete pump spare parts, a protective layer can be formed, preventing any contact between moisture, oxygen, and the metal. Consequently, the chances of corrosion are significantly reduced. This becomes particularly crucial when considering long-term storage, as the spare parts might encounter harsh environmental conditions or be stored in damp areas. Ultimately, the corrosion inhibitor coating serves to extend the lifespan of the spare parts and guarantee their preservation until they are required for use.

Send your message to us

PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords