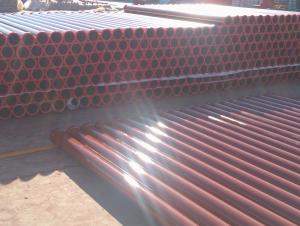

CONCRETE DELIVERY PIPE ST 52 WITH 148 FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Materials: ST 52

Concrete Pumping Capacity: about20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc)available.

Scope of Application of the Equipment

Concrete Delivery Pipe widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

Concrete Delivery Pipe are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete pipe and its major components

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Delivery Pipe according to customers request?

A4: Yes, we can produce Concrete Delivery Pipe according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: Are there any specific guidelines for the installation of sensors or transmitters in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of sensors or transmitters in concrete pump spare parts. These guidelines typically include ensuring proper alignment and positioning of the sensors or transmitters, securely mounting them to prevent movement or damage, and following manufacturer instructions for wiring and connection. It is important to adhere to these guidelines to ensure accurate and reliable operation of the sensors or transmitters in concrete pump spare parts.

- Q: How can one ensure proper documentation and record-keeping for concrete pump spare parts?

- To guarantee the appropriate documentation and record-keeping for concrete pump spare parts, one can take several measures: 1. Establishing a systematic inventory management system: A well-organized inventory management system should be implemented to track all spare parts effectively. Each part should be assigned unique codes or identification numbers, and a comprehensive inventory list should be maintained. 2. Maintaining accurate records: Detailed records should be created for each spare part, including its description, quantity, purchase date, supplier information, and cost. It is crucial to update this information regularly and make it easily accessible. 3. Implementing a standardized labeling system: Clear and consistent labels should be used on all spare parts to facilitate easy identification and location. This will minimize confusion and prevent misplacement. 4. Storing spare parts in a designated area: A specific storage area should be designated for spare parts, preferably a well-organized warehouse with proper shelving and sufficient space. This ensures secure and convenient storage. 5. Implementing a maintenance and repair schedule: A maintenance and repair schedule should be developed for the concrete pump and its spare parts. Regular inspections of all parts should be conducted, and any repairs or replacements should be documented and reflected in the inventory. 6. Training staff on documentation procedures: Employees responsible for managing spare parts should receive training on proper documentation procedures. This includes accurate recording, labeling, and updating of inventory records. 7. Performing periodic stock checks: Regular stock checks should be carried out to verify the accuracy of inventory records and identify any discrepancies. This helps identify missing or misplaced spare parts and ensures up-to-date documentation. 8. Implementing an integrated software system: An inventory management software system specifically designed for this purpose should be utilized. These systems automate documentation, track stock levels, and generate reports, enhancing efficiency and accuracy. By adhering to these measures, one can ensure proper documentation and record-keeping for concrete pump spare parts, reducing the risk of errors, improving efficiency, and guaranteeing the availability of the right spare parts when needed.

- Q: Are there any specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts. These guidelines typically vary depending on local regulations and environmental laws. It is generally recommended to follow the manufacturer's instructions for proper disposal methods. This may involve recycling the hydraulic fluids or disposing of them at designated waste management facilities to ensure minimal environmental impact.

- Q: What are the different types of concrete pump hopper cylinders seals?

- There are several different types of concrete pump hopper cylinder seals, each designed to meet specific needs and requirements. Some of the most common types include: 1. Piston seals: These seals are designed to prevent leakage between the piston and cylinder bore. They are typically made of durable materials such as rubber or polyurethane, and are resistant to abrasion and wear. 2. Rod seals: Rod seals are installed on the piston rod to prevent leakage between the rod and cylinder head. They are often made of materials such as rubber or fabric-reinforced rubber, and provide reliable sealing even under high pressure conditions. 3. Wiper seals: Wiper seals are used to remove dirt, dust, and other contaminants from the piston rod as it retracts into the cylinder. They are typically made of polyurethane or rubber, and are designed to provide effective sealing and protection for the cylinder. 4. Wear rings: Wear rings are used to reduce friction and prevent metal-to-metal contact between the piston and cylinder bore. They are typically made of materials such as bronze or Teflon, and help to extend the lifespan of the cylinder by reducing wear and tear. 5. Backup rings: Backup rings are used in conjunction with other seals to provide additional support and stability. They are typically made of materials such as rubber or PTFE, and help to prevent extrusion and damage to the primary seal. Overall, the selection of the appropriate concrete pump hopper cylinder seal depends on factors such as the specific application, operating conditions, and desired performance characteristics. It is important to choose seals that are compatible with the pumped material, provide effective sealing, and have a long lifespan in order to ensure optimal performance and minimize maintenance requirements.

- Q: How often should concrete pump pressure gauges be inspected and replaced?

- Regular inspections of concrete pump pressure gauges are necessary to ensure they are accurate and functioning properly. The frequency of inspections and replacements may vary depending on the specific conditions and usage of the pump. However, it is generally recommended to inspect and replace pressure gauges at least once a year or after every 500 pumping hours, whichever comes first. This regular schedule helps prevent any potential accuracy or functionality issues that could impact the safety and efficiency of the pumping operations. It is also essential to adhere to the manufacturer's recommendations and guidelines for pressure gauge maintenance and replacement to maintain optimal performance and longevity.

- Q: What are the different types of concrete pump rubber hoses?

- There are several different types of concrete pump rubber hoses available, including wire-reinforced hoses, fabric-reinforced hoses, steel wire braided hoses, and composite hoses. These hoses are designed to withstand the high pressure and abrasive materials involved in pumping concrete, ensuring safe and efficient operations.

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: What are the advantages of using tungsten carbide components in concrete pump spare parts?

- There are several advantages of using tungsten carbide components in concrete pump spare parts. Firstly, tungsten carbide is an extremely hard and durable material, which ensures longer lifespan and increased wear resistance of the components. This means reduced maintenance and replacement costs in the long run. Additionally, tungsten carbide has excellent corrosion resistance, making it suitable for use in harsh and corrosive environments commonly found in concrete pumping applications. Furthermore, tungsten carbide components offer superior strength and toughness, enabling them to withstand high-pressure and heavy-duty operations without compromising performance. Overall, the use of tungsten carbide in concrete pump spare parts leads to improved efficiency, reliability, and cost-effectiveness in concrete pumping operations.

- Q: What is the function of a concrete pump water pump?

- The primary role of a water pump in a concrete pump system is to provide water for various purposes. Its main responsibility is to ensure a continuous water flow to the concrete pump, which aids in the efficient mixing and pumping of concrete. By adding water when necessary during the pumping process, the water pump guarantees that the concrete mixture maintains the desired consistency. It plays a crucial role in controlling the hydration process of the cement, preventing it from drying out and becoming unworkable. Furthermore, the water pump also plays a vital role in cleaning the concrete pump system after use. It effectively flushes out any excess concrete residue or debris that may have accumulated inside the pump, thus ensuring its optimal operational condition. To summarize, the concrete pump water pump functions to supply water for concrete mixing, maintain the desired consistency, and clean the concrete pump system.

- Q: How often should hopper vibrators be inspected or replaced in a concrete pump?

- To ensure the proper functioning of hopper vibrators in a concrete pump and prevent any potential problems, it is important to conduct regular inspections. The frequency of these inspections or replacements may vary depending on several factors, such as the intensity of use, operating conditions, and the manufacturer's recommendations. As a general rule, it is recommended to inspect hopper vibrators at least once a year or after every 500-600 hours of operation, whichever comes first. However, if the concrete pump is heavily used or operates in harsh environments, more frequent inspections may be necessary. During the inspection, it is essential to check the hopper vibrators for any signs of wear, damage, or loose connections. Additionally, the vibration intensity and frequency should be assessed to ensure they are within the recommended range. Any issues identified during the inspection should be promptly addressed through repairs or replacements to ensure the hopper vibrators continue to function effectively. Regular inspections and timely replacements of hopper vibrators are crucial for maintaining the efficiency and reliability of a concrete pump. Neglecting these inspections can result in decreased performance, increased downtime, and potentially expensive repairs. Therefore, it is important to adhere to the manufacturer's guidelines and seek professional advice to determine the appropriate frequency for inspections and replacements based on the specific circumstances of your concrete pump.

Send your message to us

CONCRETE DELIVERY PIPE ST 52 WITH 148 FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords